Process for the oligomerization of butenes

A technology of polybutene and butene, applied in chemical instruments and methods, hydrocarbons, hydrocarbons, etc., to achieve the effects of good separation, low investment cost, and energy saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

[0141] Examples 1-3 exemplify the following advantages by converting the dried unsaturated C 4 The reflux of the hydrocarbon stream to the oligomerization reaction is achieved.

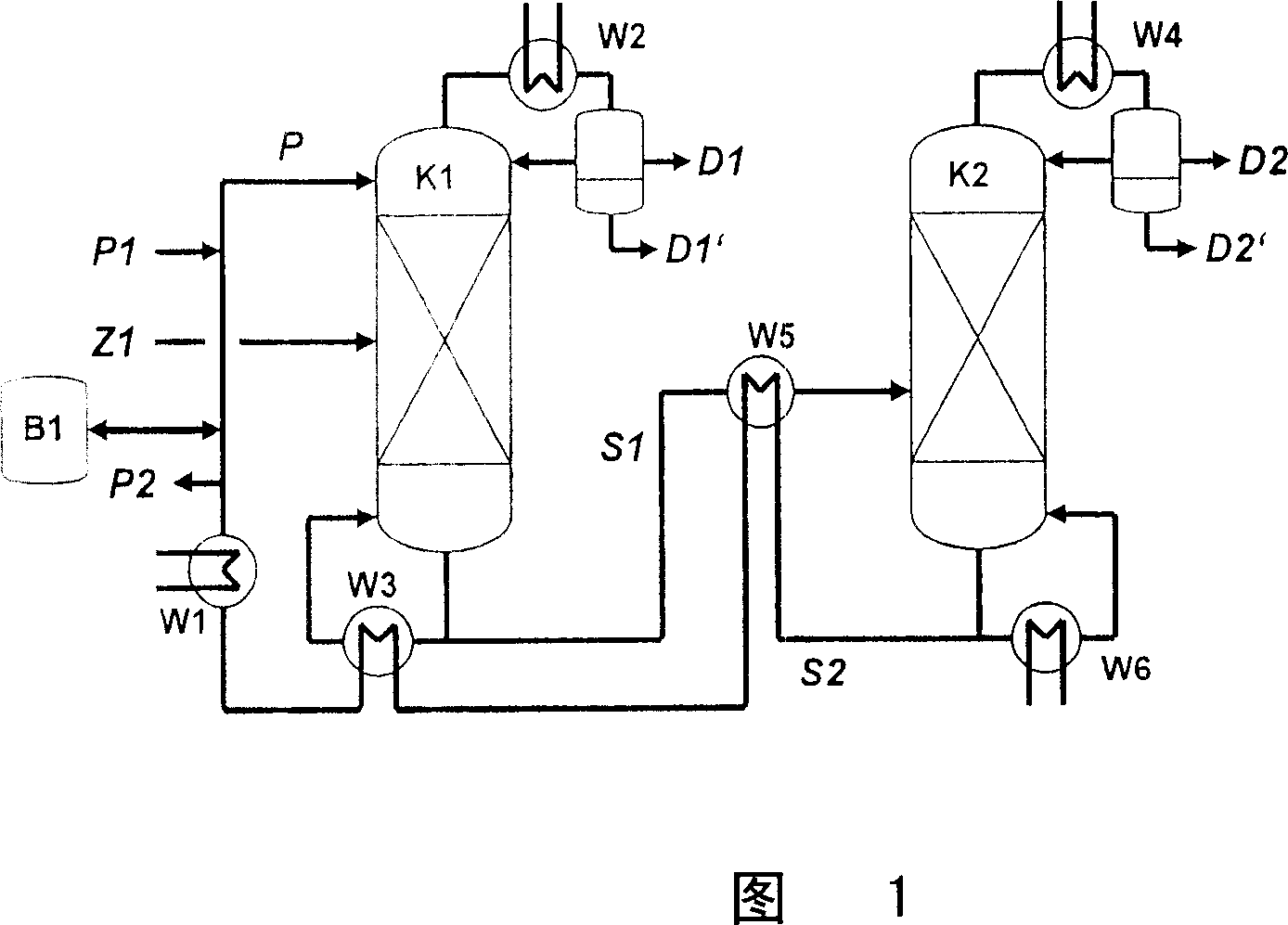

[0142] The schematic structure of the device proceeds corresponding to FIG. 11 . Feed stream Z1 supplied to unit F1 is obtained by separating unconverted C from the oligomerization product 4 Hydrocarbons obtained, in unit F1 C 4 The hydrocarbons are separated into a stream enriched in n-butanes (D1) and a stream enriched in n-butenes (D2). The butene-rich stream (D2) obtained in F1 is subsequently washed and dried in unit F2. The resulting C 4 The hydrocarbon stream S4 is fed to the oligomerization reaction together with the feed stream Z3.

[0143] According to known prior art, the oligomerization was carried out in a mobile phase in a tube bundle reactor at a reaction temperature of 80° C. over a heterogeneous nickel catalyst (prepared analogously to US 5169824, Example 1). Distillation to sep...

Embodiment 4 and 5

[0149] Examples 4 and 5 show the effect of unit F2 on the activity of heterogeneous nickel catalysts in oligomerization reactions.

[0150] The experiments were performed in a pilot scale facility. As a reactor for the oligomerization reaction, an externally temperature-adjustable tube having an inner diameter of 2 cm and a length of 200 cm was used, and a heterogeneous nickel catalyst was filled in the tube. The reactor temperature was adjusted to 90 °C and C was supplied from above 4 hydrocarbon. Samples were drawn at the reactor inlet and reactor outlet and analyzed for their composition by gas chromatography. by C 4 The hydrocarbon composition (n-butane as internal standard) determines the conversion achieved in the oligomerization.

[0151] The raw materials used in the experiments were obtained from large industrial plants. In run 4, after drying in the water wash and drying tower, there was essentially no acetonitrile. In Test 5, 2.5 ppm of acetonitrile was contai...

Embodiment 6-8

[0156] The advantage of preheating the feed to the exhaust column (stage b) with the thermal energy of the bottom stream of stage b) is demonstrated with the aid of the following examples. The feed stream of 225 t / h consisted of a mixture of 89.2% by mass of NMP, 8.1% by mass of water and 2.7% by mass of butenes. The exhaust column has 12 theoretical separation stages with 6 feed stages and operates at 0.5 MPa. The calculations were performed using AspenTech's simulation software AspenPlus version 12.1. The model was fitted to experimentally measured phase equilibrium data.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com