Apparatus for cleaning and transporting coal-mine water sump slurry

A technology of transportation device and water tank, which is applied in transportation and packaging, underground transportation, earthwork drilling and mining, etc. It can solve the problems of poor control of loading volume, pollution along the transportation, and the impact of normal use of transportation safety facilities, etc., and achieve economic benefits Significant and social benefits, convenient safety production organization management, and simplified safety production organization management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

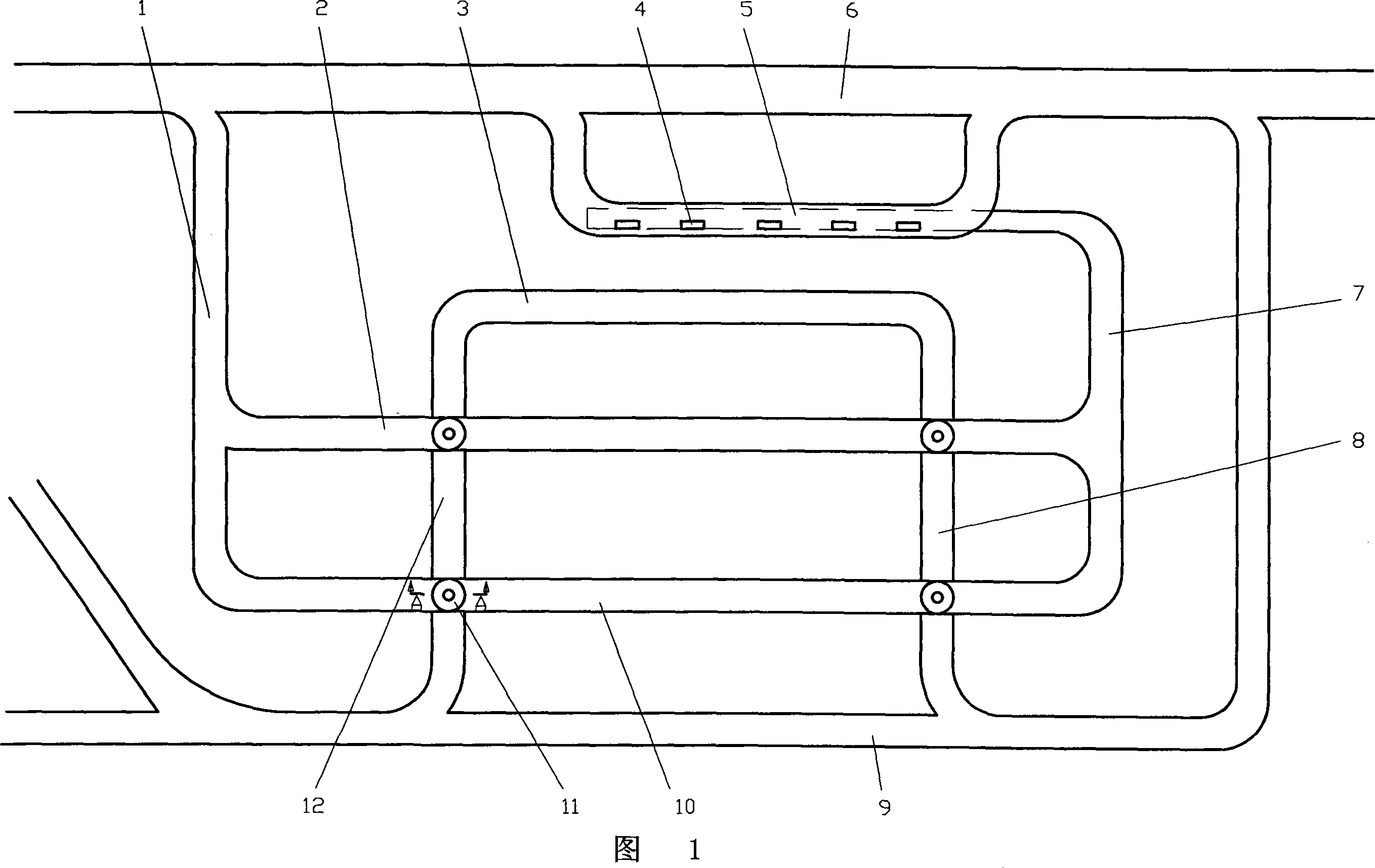

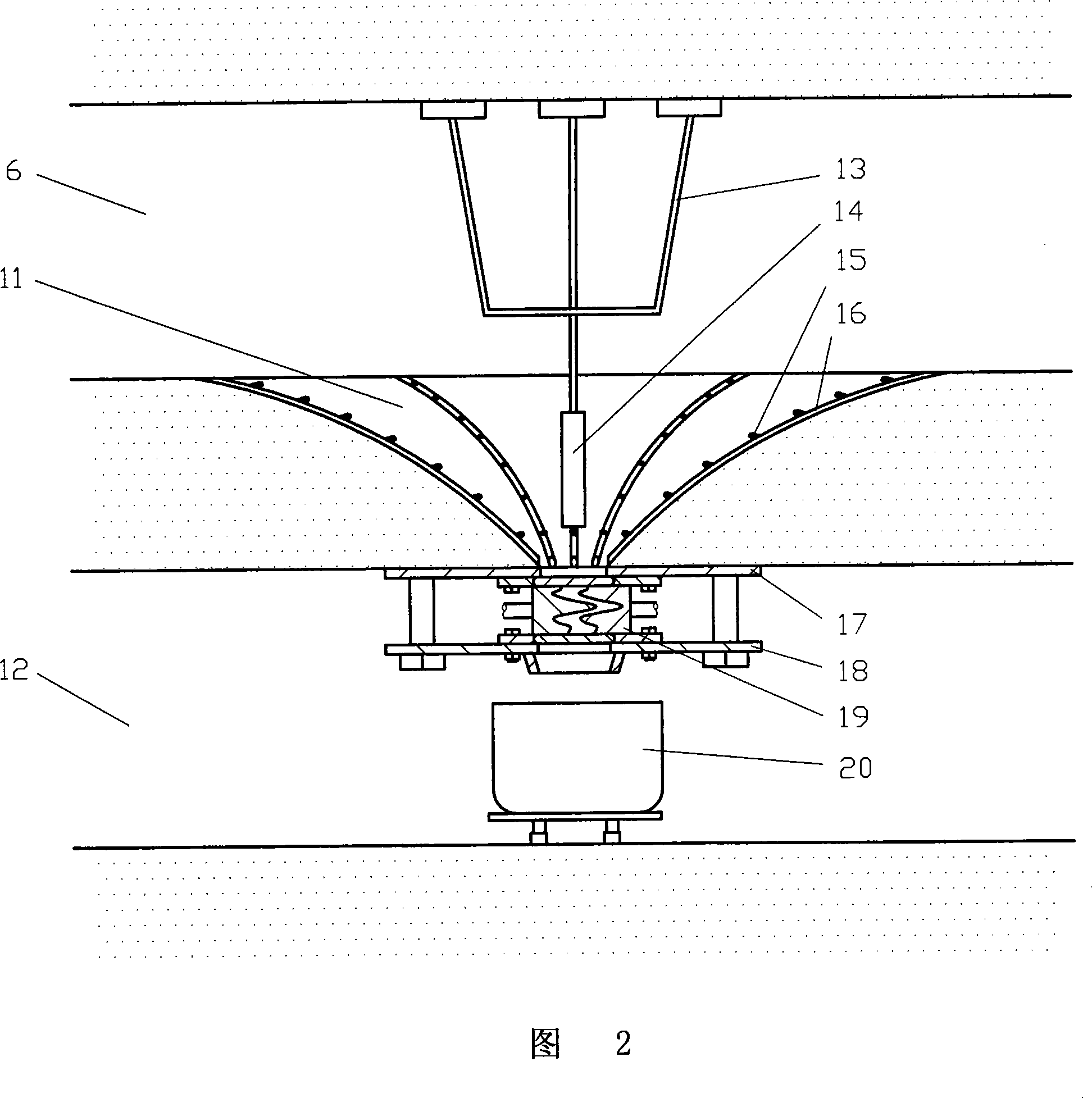

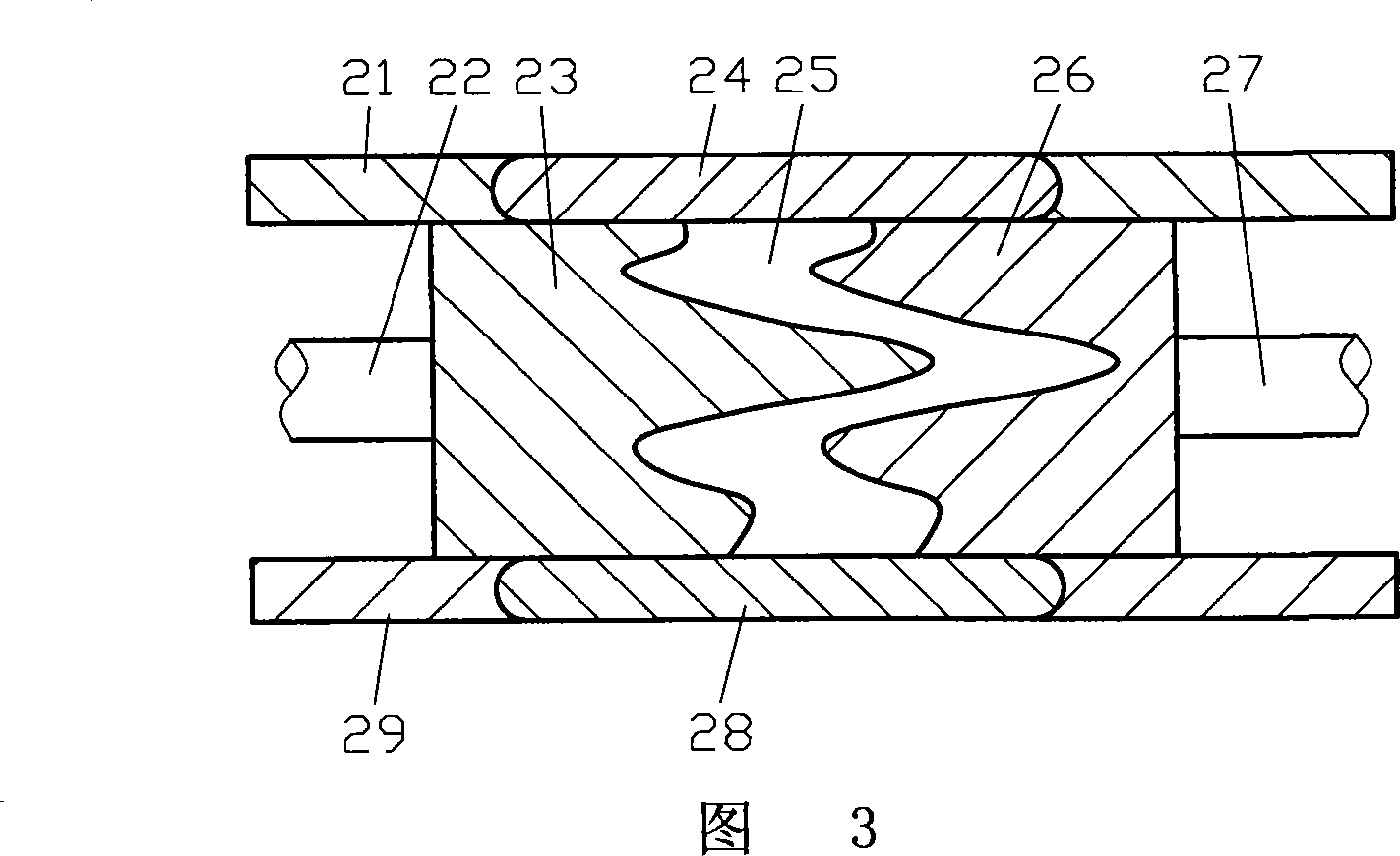

[0020] As shown in Figure 1, a central pump room 5 (elevation -600m), inner and outer central water tanks 2 and 10 (entrance elevation -609m, exit elevation -608m), detour 9 (elevation -600m), the inner and outer central water tanks 2 and 10 communicate with the transportation lane 6 through the water inlet channel 1, communicate with the central pump room 5 through the connecting road 7 (elevation -607m), and the central pump There is a small well 4 for extraction in the room 5. The detour 9 communicates with the transportation alley 6. The lower ends of the inner and outer central water tanks 2 and 10 are provided with left and right discharge lanes 12 and 8 (both with an elevation of -614m) and a connecting lane 3 (with an elevation of -614m). Lane 3 communicates, and communicates with bypass 9 through an upward ramp. There is a vertical discharge hole 11 between the inner and outer central water tanks 2, 10 and the left and right discharge lanes 12, 8. The discharge hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com