Fly ash charcoal-removing parallel plate electrostatic separator and friction charged electrostatic field sorting process

An electrostatic separator, fly ash technology, applied in electrostatic effect separation, solid separation, chemical instruments and methods, etc., to achieve the effect of small maintenance, low power consumption and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

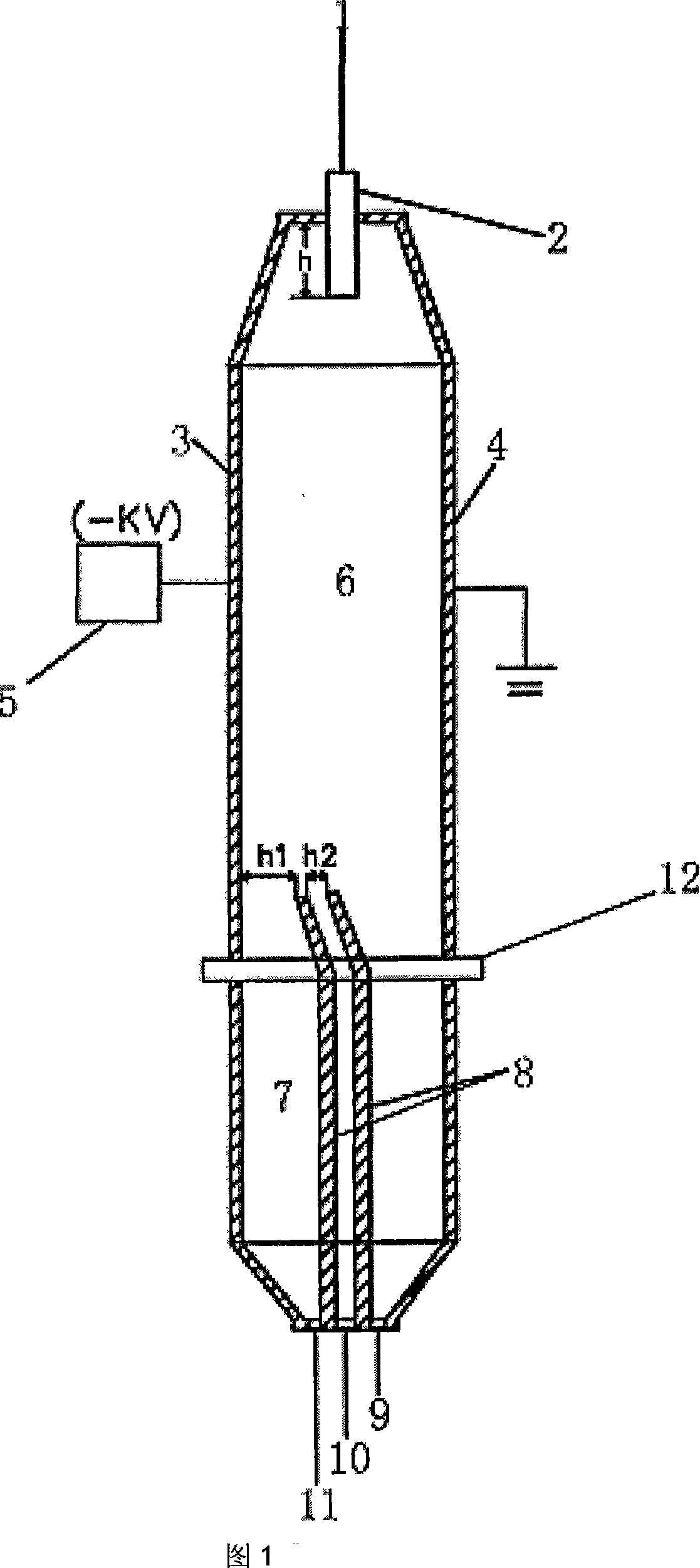

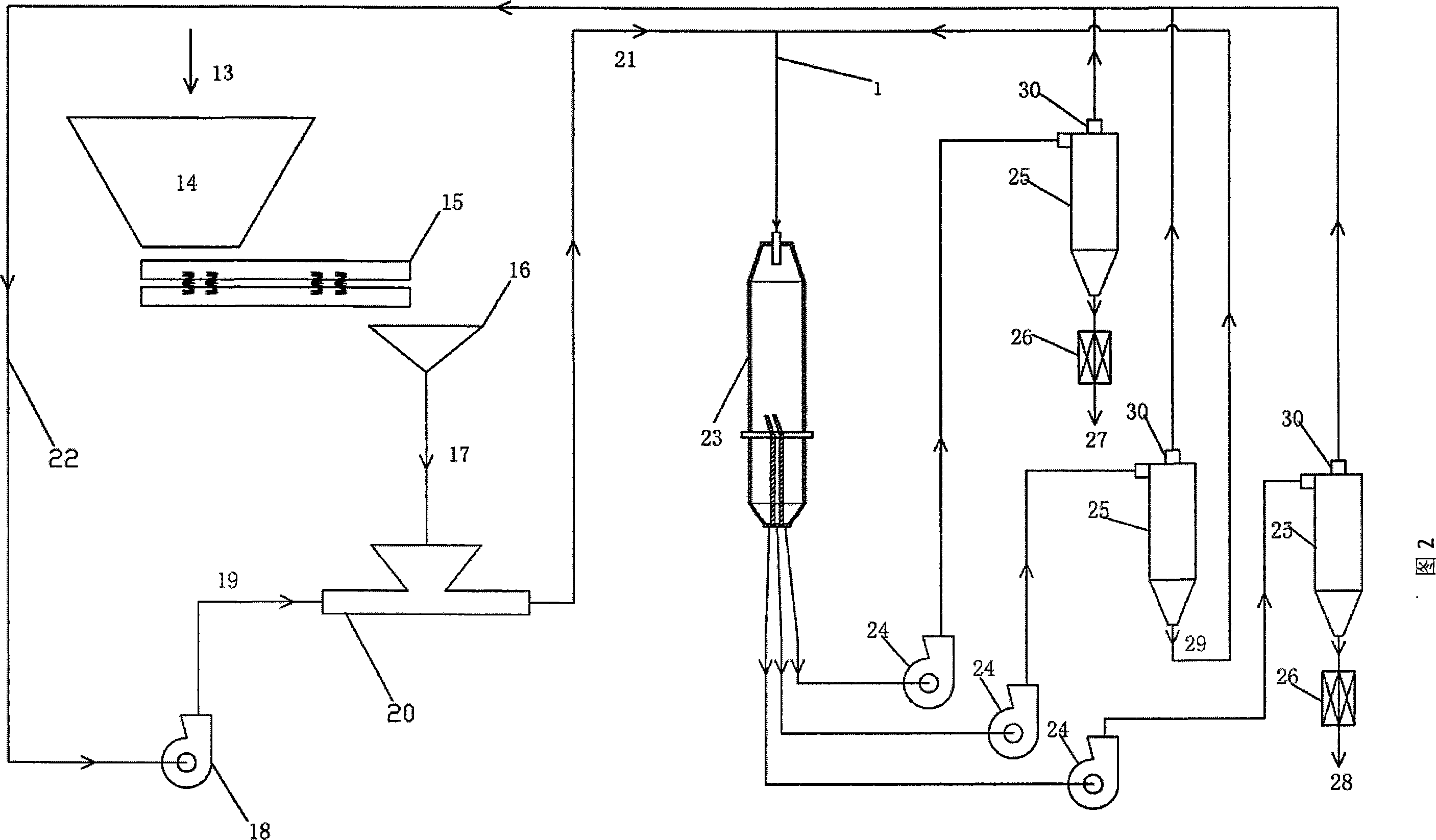

[0023] Here, the present invention is further illustrated by examples. Two kinds of fly ash raw ash from a certain coal-fired power plant in Shaanxi are selected, which are characterized by a high loss on ignition index (8%-25%). Sorting is carried out by using the triboelectric electrostatic field sorting process shown in the accompanying drawing.

[0024] SiO 2

[0025] Operating process and conditions

[0026] The guide for the parallel plate electrostatic separator used had an inner diameter of 80 mm and an insertion depth h of 125 mm. First turn on the 2.1kV negative high voltage generator power supply to make the electrostatic separation chamber generate a high voltage electric field with a field strength of 200kV / m. And start the blower of each product to make the electrostatic separator system enter the working state. Then start the feeding system: first turn on the carrier gas blower of the pneumatic conveyor, and blow air to the pneumatic conveyor. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap