Real time monitoring device of the three-dimensional laser beam welding and incising process

A real-time monitoring and three-dimensional laser technology, applied in laser welding equipment, welding equipment, program control, etc., can solve the problems of simultaneous acquisition, difficulty in accurately judging welding and cutting quality, narrow application range, etc., to achieve real-time quality monitoring, Realize the effect of penetration monitoring and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

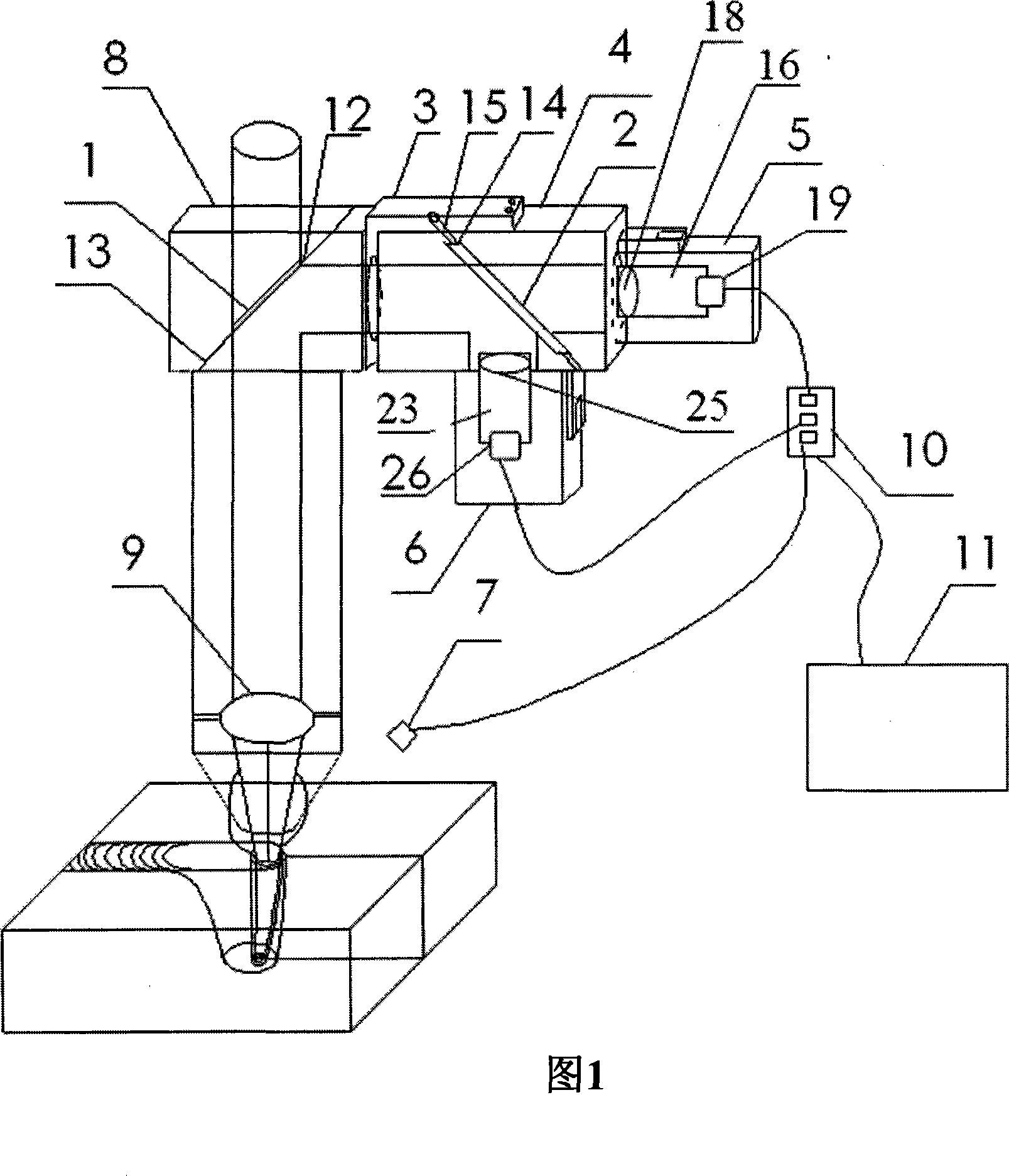

[0023] Explain the specific embodiment of the present utility model below in conjunction with accompanying drawing:

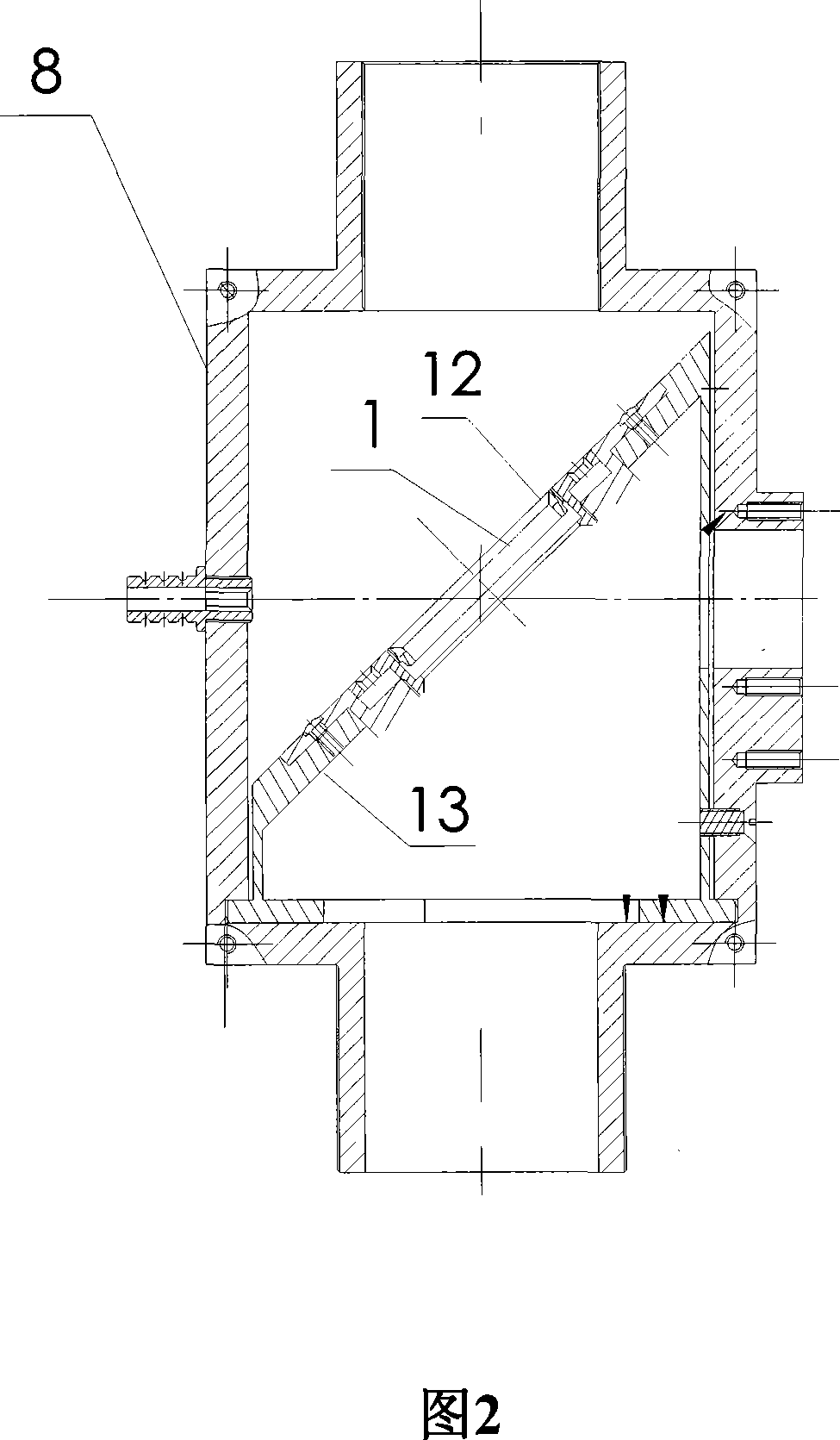

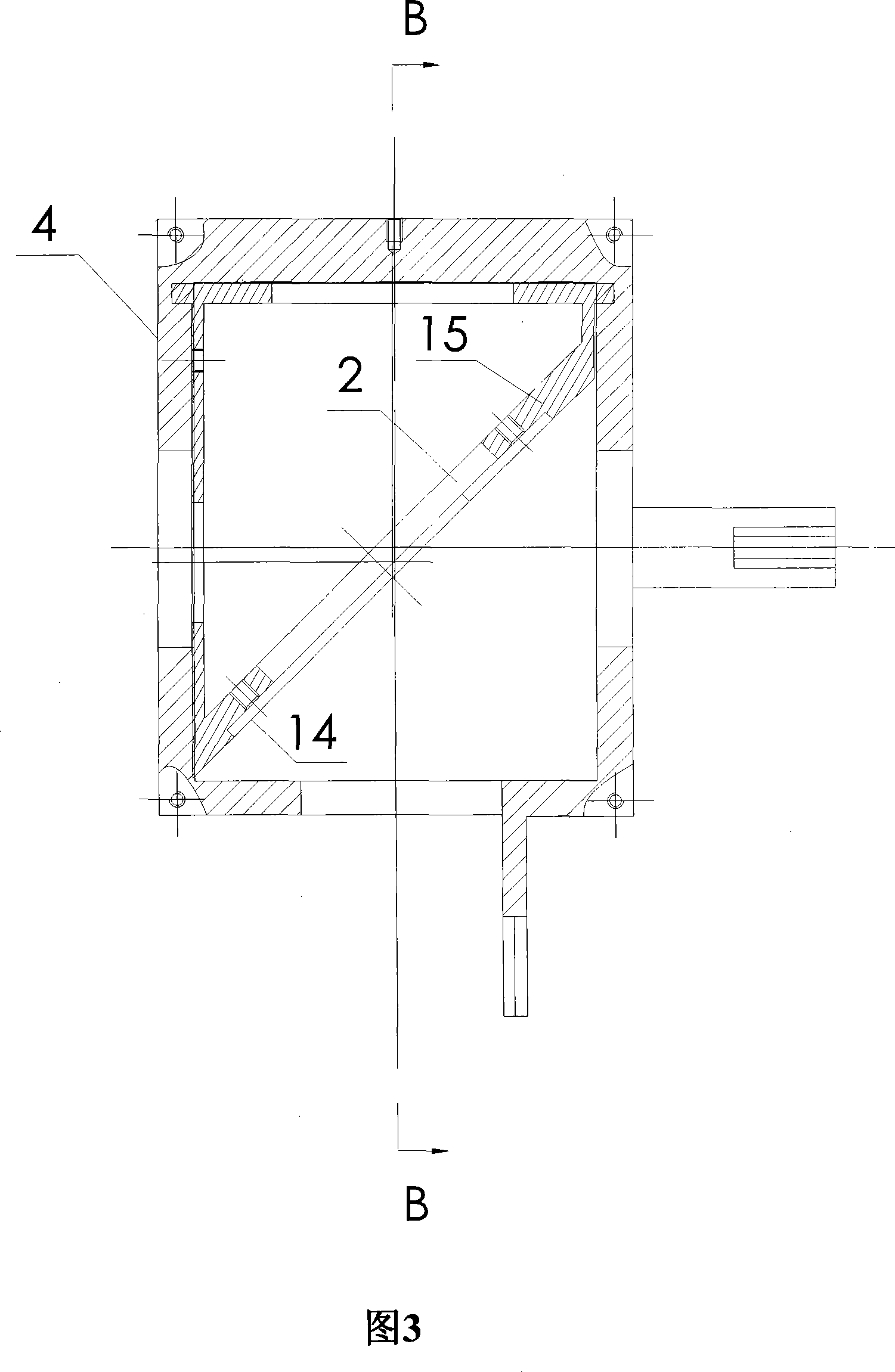

[0024] Figure 1 shows a schematic diagram of a coaxial monitoring device for three-dimensional laser welding and cutting processes. The light guide mirror 1 is fixed on the first lens support 13 by the first lens pressure ring 12, and the first lens support 13 is fixed on the main box 8. middle. The laser focusing mirror 9 is fixed in the mechanism above the nozzle. The beam splitter 2 is fixed on the second lens support 15 by the second lens pressure ring 14 , and the second lens support 15 is fixed in the side box 4 . The connecting plate 3 connects the main box body 8 on the left side and the side box body 4 on the right side. The infrared photoelectric sensor clamping tube 5 used to collect infrared radiation light is fixed on the convex plate on the right side of the side box 4 by bolts, and the photoelectric sensor clamping tube 6 used to collect plasma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com