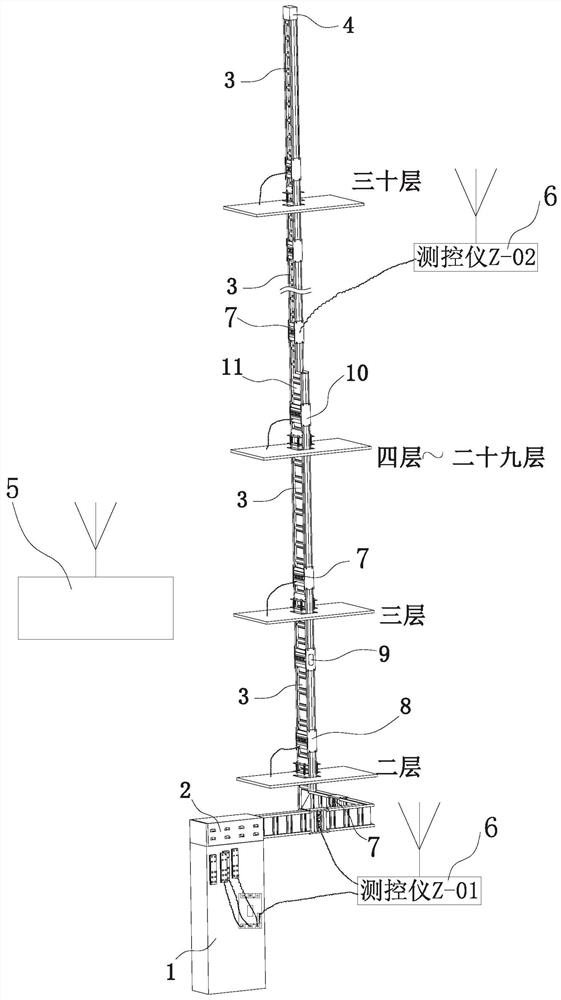

Copper-aluminum alloy intelligent bus trunk line system

A copper-aluminum alloy and busbar technology, which is applied in the installation of busbars, fully enclosed busbar devices, and information technology support systems, etc., can solve problems such as engineering safety hazards, waste of resources, and copper stealing from busway, to improve safety performance, The effect of reducing project cost and improving flow capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

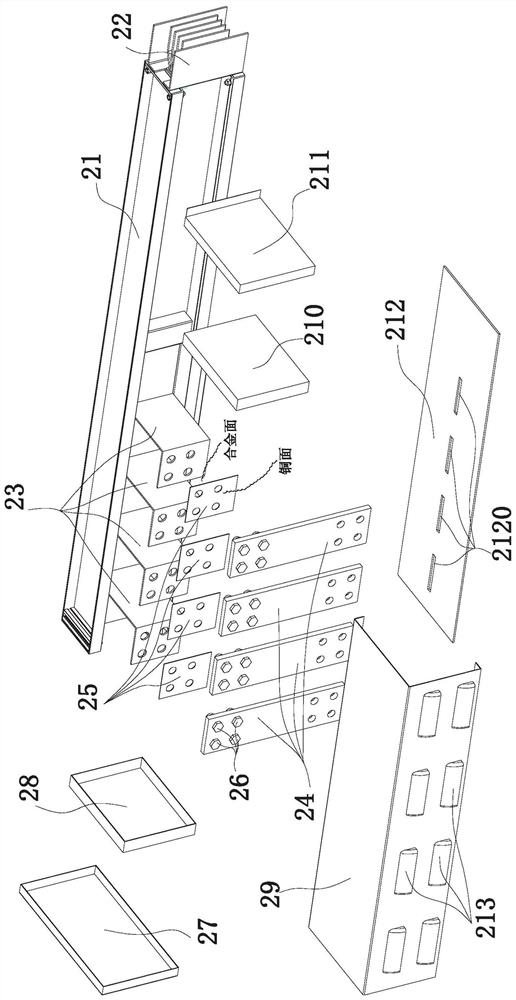

[0121] Such as Figure 2 to Figure 4As shown, the busway start section includes a shell assembly, a conductor assembly, a busbar body 21 using an aluminum alloy conductor, and a busbar connection end 22; the busbar connection end 22 is connected to one end of the busbar body 21, and the conductor assembly connection end is connected to the busbar body The other end of 21 is sealed by the cover of the shell assembly; four sets of aluminum alloy busbars 23 are arranged on the busbar body 21, and the corresponding conductor assembly is provided with a starting copper bar that is connected with each set of aluminum alloy busbars 23 24. Between the butt joint surfaces of each group of aluminum alloy busbars 23 and the corresponding butt joint copper bars 24, a copper-aluminum alloy cladding sheet 25 is respectively attached to the inner surfaces of the two. The copper-aluminum alloy cladding sheet 25 adopts Copper-aluminum clad double-layer structure with a thickness of 1.0mm, the ...

Embodiment 2

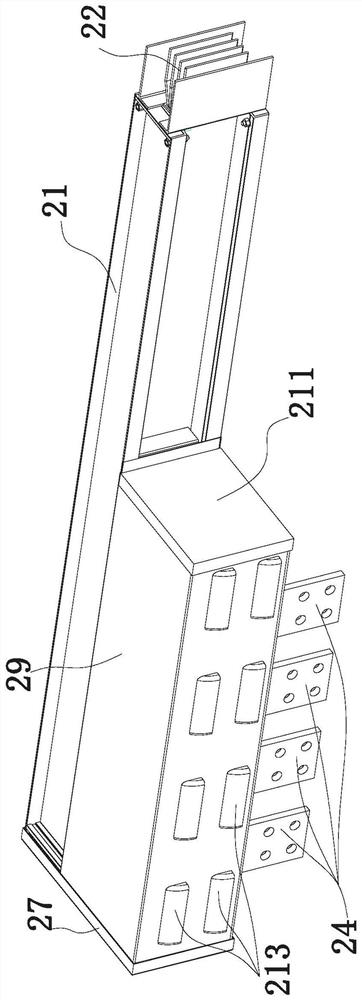

[0126] Such as Figure 5 and Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the ends of the bus bar body 21 are evenly spaced apart along the width direction, and there are four sets of aluminum alloy bus bars 23 distributed in a step-shaped dislocation at the end faces, and the corresponding conductors The four groups of starting copper bars 24 on the assembly are respectively superimposed with copper-aluminum alloy cladding sheets 25 and then connected to the outer edge of each group of aluminum alloy bus bars 23, and protrude from the lower side of the housing assembly in the vertical direction.

[0127] Wherein, the housing assembly is a rectangular parallelepiped box wrapped around the aluminum alloy busbar 23 and the outer end. The inner supporting plate 215 supported on the right side of the housing, the top outer sealing plate 216 for the top side cover, the front side support frame and outer sealing plate 217 for the front side su...

Embodiment 3

[0131] Such as Figure 7 to Figure 10 As shown, the busbar connector 8 is used for the connection of the aluminum joint busbar 83 between the two adjacent butt first busbar slots 81 and the second busbar slots 82, including a front connecting side plate 84 and a rear connecting side plate 85, The front connection side plate 84 and the rear connection side plate 85 are used for the sealing of the front and rear sides of the joint busbar 83, and the connection and fixation between the front and rear ends of the first bus duct 81 and the second bus duct 82; The slot 81 and the second bus slot 82 are butted with the joint busbar 83 adjacent to the side, and five groups are provided for conducting connection between the joint busbars 83 and insulating connection between adjacent joint busbars 83 Part 86, the insulating connector 86 includes an insulating partition 860, two copper connecting pieces 861 and two copper-aluminum alloy cladding sheets 862, the insulating partition 860 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com