Preparation technique for abstraction of inulin from chicory

A preparation process, the technology of chicory, applied in the chemical extraction process, the field of preparation process for extracting inulin, can solve the problems of low purity and yield of inulin, complicated process, long extraction time, etc., and achieve enhanced extraction purity and yield, extraction process Reasonable and shortened extraction time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

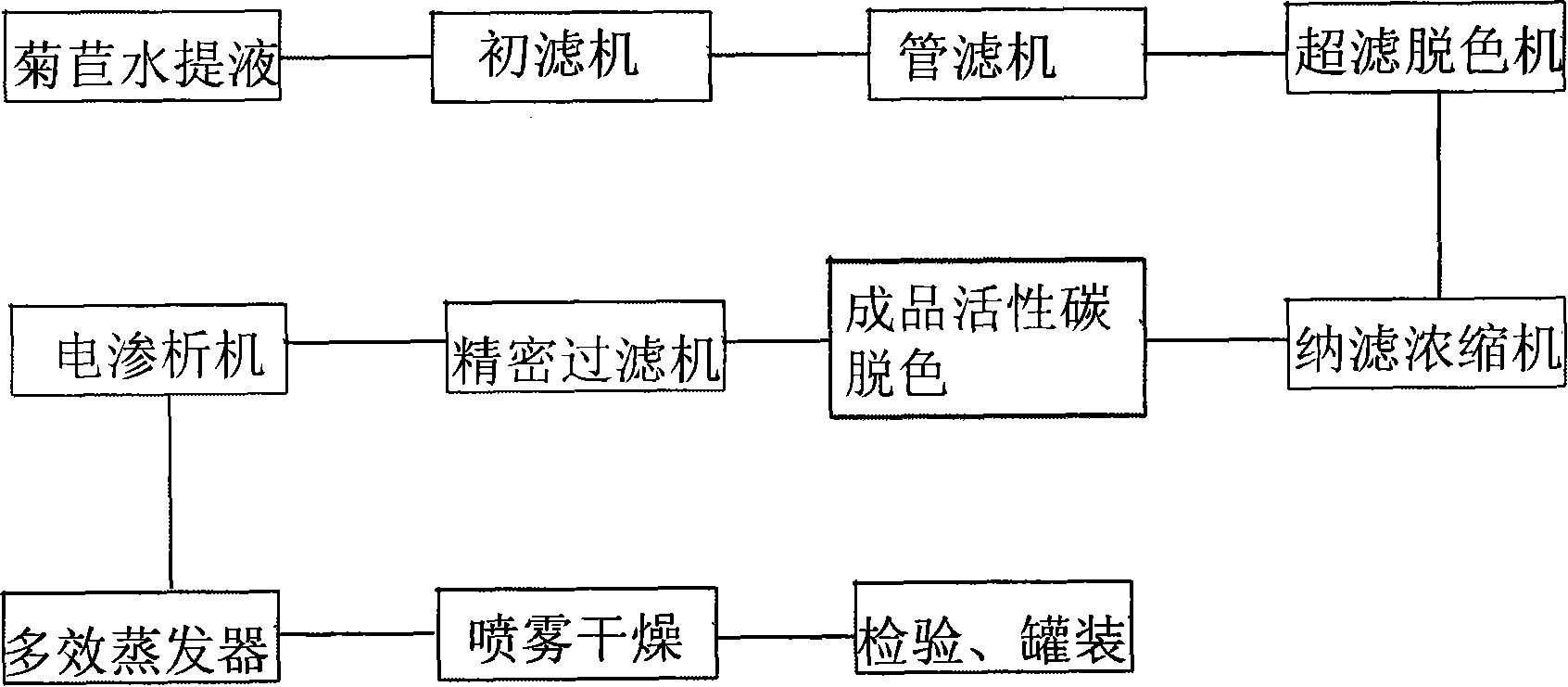

[0026] Extraction process of the present invention comprises the following steps:

[0027] Cleaning: remove impurities from fresh chicory rhizomes and wash them with water;

[0028] Broken: the washed chicory rhizomes are processed and cut into shreds;

[0029] Extraction: extract the rhizome of chicory processed into silk in countercurrent with water, the water consumption is 8 times that of the rhizome of chicory, the temperature is controlled at 50°C, the extraction time is 60min, until the residue remains, and the water extract A is obtained;

[0030] Filtration: Filter the residue in the extraction through the primary filter, tube filter, and ultrafiltration decolorization machine in sequence. The filtration temperature of the ultrafiltration decolorization machine is controlled at 40°C, and the recovery rate is controlled at 90%, to obtain filtrate B;

[0031] Nanofiltration concentration: the water extract A and filtrate B are filtered and concentrated by a nanofiltrat...

Embodiment 2

[0038] In the extraction step, the water consumption is 6 times that of the rhizome of chicory, the temperature is controlled at 40° C., and the extraction time is 80 minutes;

[0039] In the filtration step, the filtration temperature of the ultrafiltration decolorization machine is controlled at 30°C, and the recovery rate is controlled at 90%;

[0040] In the nanofiltration concentration step, the temperature is controlled at 35°C, the recovery rate is controlled at 50%, and the concentrated concentration is controlled at 18 B2iX;

[0041] In the decolorization step, the decolorization is carried out at 30°C, the concentrated solution C:activated carbon=350:1;

[0042] In the evaporation and concentration step, the water evaporation rate is 260Kg / H, the water content is controlled at 20%, and the concentration is concentrated to a solid content of 18%;

[0043] In the drying step, spray drying was carried out at 150° C., and other steps were the same as in Example 1.

Embodiment 3

[0045] Choose dried chicory, in the extraction step, the water consumption is 10 times that of chicory rhizome, the temperature is controlled at 60°C, and the extraction time is 40min;

[0046] In the filtration step, the filtration temperature is controlled at 50°C, and the recovery rate is controlled at 100%;

[0047] In the nanofiltration concentration step, at 55°C, the recovery rate is controlled to 70%, and the concentrated concentration is controlled to 28 B2iX;

[0048] In the decolorization step, the decolorization is carried out at 50° C., concentrated solution C:activated carbon=500:1;

[0049] In the evaporation and concentration step, the water evaporation rate is 150Kg / H, the water content is controlled at 40%, and the concentration is concentrated to a solid content of 40%;

[0050] In the drying step, spray drying is carried out at 200° C., and the water content is lower than 5%. The other steps are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com