Method for bleaching gauze by employing ozone water

A technology of ozone water and gauze, which is applied in the direction of bleaching products, textiles and papermaking, etc. It can solve problems such as uneven concentration, uneven bleaching, and inability to simply transplant gauze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

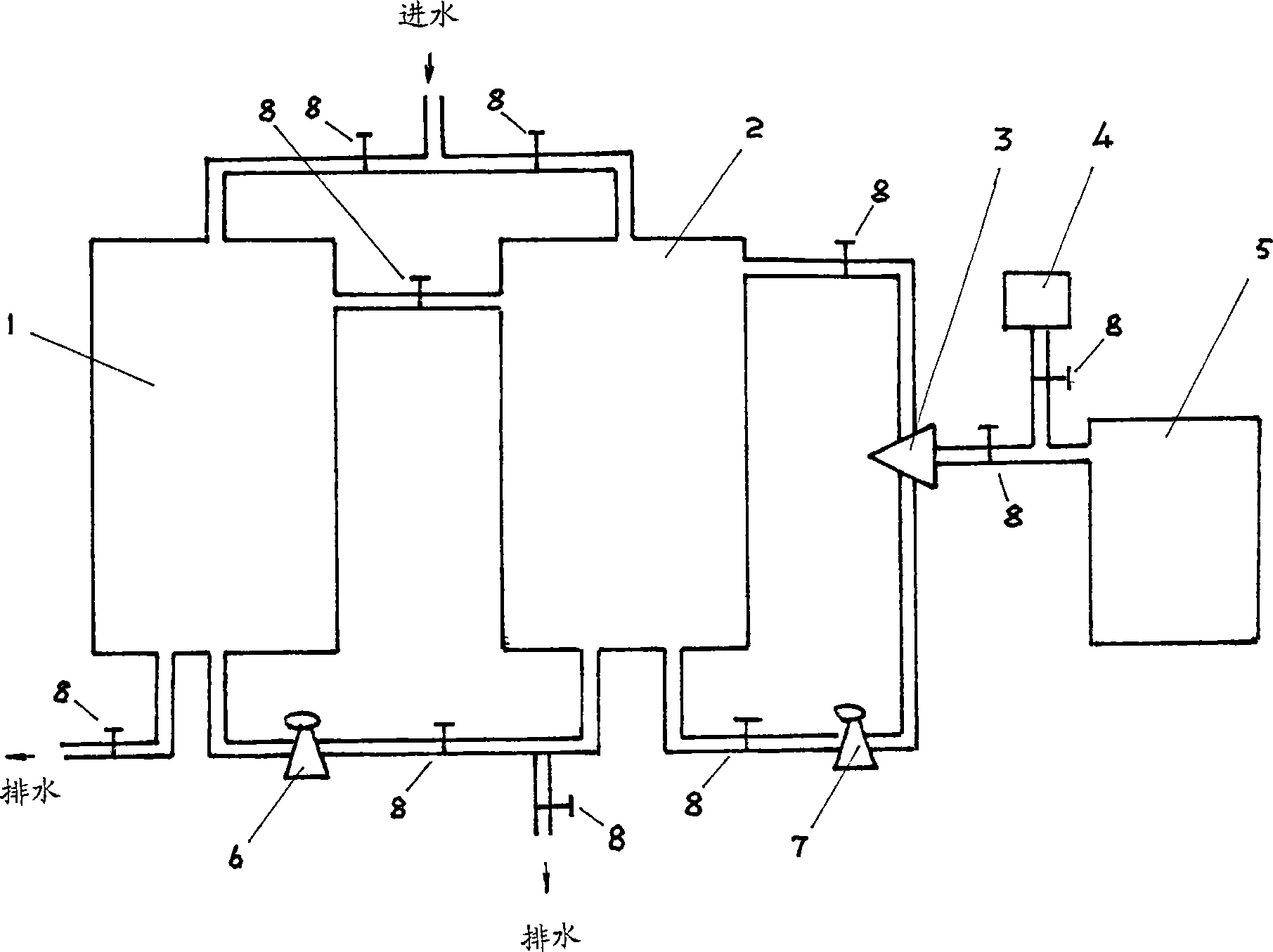

Image

Examples

Embodiment 1

[0013] Put 10,000 meters of gauze into the bleaching pot, pour in demineralized water, and scour the gauze with high-efficiency compound enzymes. After scouring, the gauze is washed with alkali and water, and the water in the pot is removed. Prepare 1.2 tons of water with a pH value of 4.5 in the batching tank, add 600g of surfactant 601, turn on the ozone generator, open all the electrolytic cells of the ozone generator at the same time, ventilate for about 60 minutes, and the ozone concentration in the water reaches 0.018g / L. 0.8 tons of ozone water in the batching barrel are squeezed into the bleaching pot, and the initial concentration of ozone water in the bleaching pot is 0.016g / L. The remaining 0.4 tons of water continue to pass through the ozone in the material tank, and the ozone water in the material tank and the bleaching pot become an external circulation system through the pump. The concentration of ozone water is adjusted by changing the number of electrolytic c...

Embodiment 2

[0015] Put 10,000 meters of gauze into the bleaching pot, add demineralized water, and use high-efficiency compound enzymes to scour the gauze. After scalding, the gauze is washed with alkali and water, and the water in the pot is drained. Prepare 1.0 tons of water with a pH value of 5 in the batching tank, add 500g of surfactant 601, turn on the ozone generator, open all the electrolytic cells of the ozone generator at the same time, ventilate for about 30 minutes, and the ozone concentration in the water reaches 0.018g / L. Pour 0.8 tons of ozone water in the batching barrel into the bleaching pot, and measure the initial concentration of ozone in the bleaching pot to be 0.016g / L. The remaining 0.2 tons of water continue to pass through the ozone in the batching tank, and the ozone water in the batching tank and the bleach pot become an external circulation system through a pump. Adjust the concentration of ozone water by changing the number of electrolytic cells used in the o...

Embodiment 3

[0017] Put 10,000 meters of gauze into the bleaching pot, pour in demineralized water, and scour the gauze with high-efficiency compound enzymes. After scouring, the gauze is washed with alkali and water, and the water in the pot is removed. Prepare 1.4 tons of water with a pH value of 5.5 in the batching tank, add 700g of surfactant 601, turn on the ozone generator, open all the electrolytic cells of the ozone generator at the same time, ventilate for about 30 minutes, and the water temperature is 20 ° C. The ozone concentration in the water reaches 0.018 g / L. 0.8 tons of ozone water in the batching barrel is driven into the bleaching pot, and the initial concentration of ozone in the bleaching pot is measured to be 0.015g / L. The remaining 0.6 tons of water continue to pass through the ozone in the material tank, and the ozone water in the material tank and the bleaching pot become an external circulation system through the pump. Adjust the concentration of ozone water by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com