Wood-plastic foam rise, steel tube combined pipes and formula thereof

A wood-plastic foaming and combined pipe technology, applied in building elements, slender elements, etc., can solve the problems of waste of resources, inconvenient installation, and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

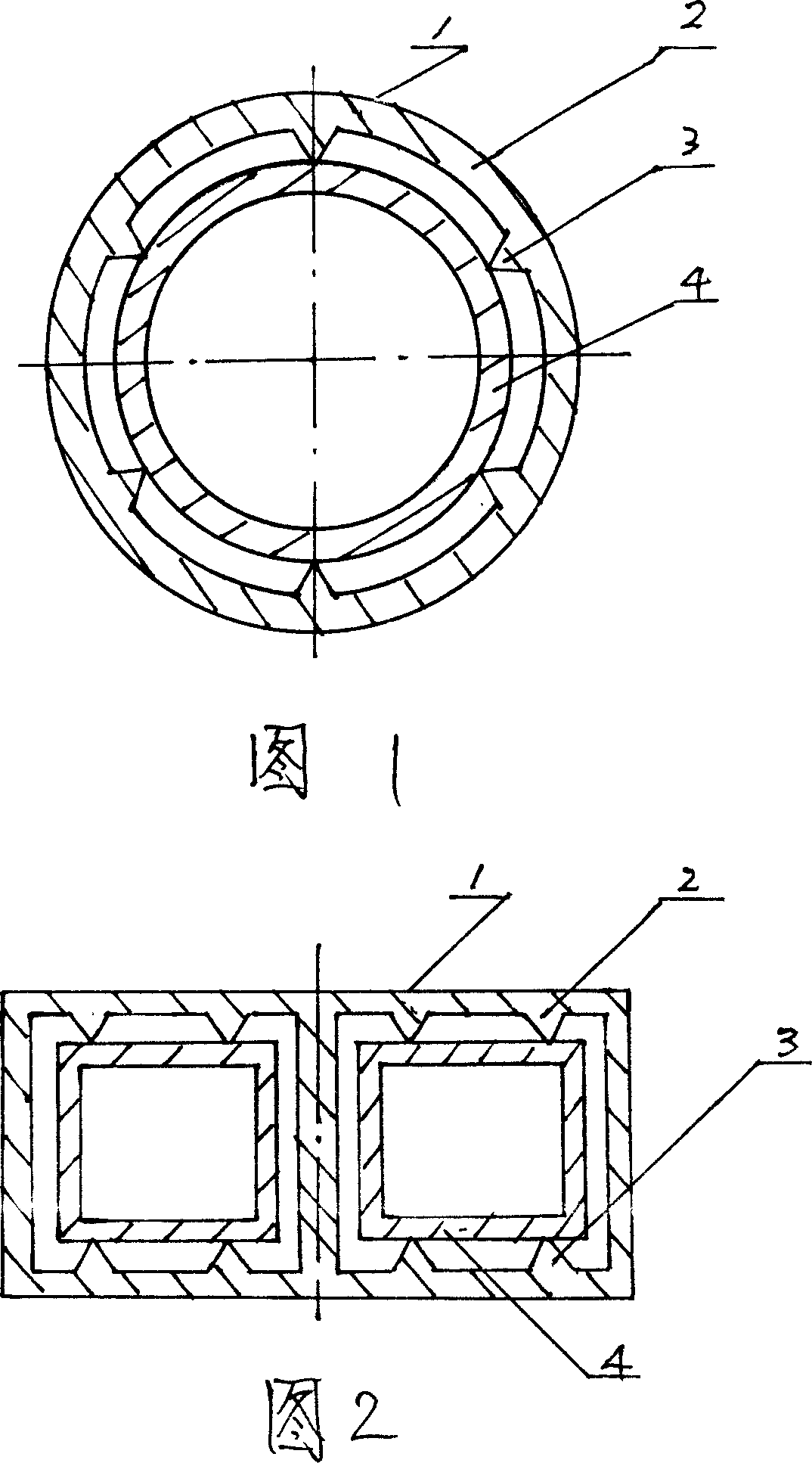

[0029] See accompanying drawing 1, a kind of circular wood-plastic foaming, steel pipe composite pipe, according to thermal transfer hot stamping foil (1), wood-plastic foaming pipe (2), the inner wall is evenly distributed with 6 triangular reinforcing ribs ( 3), the structure in which the steel pipe (4) is arranged in the inner circle at the top of the reinforcing rib (3).

[0030] Its manufacturing method: according to the material composition ratio of the wood-plastic foam pipe (calculated by weight percentage), the crop straw straw fiber is crushed into 80-100 mesh powder, and the surface is treated; all the main materials, auxiliary agents, fillers Put it into a high-speed mixer, perform high-speed stirring, fully mix, and heat up. When the temperature rises to 75°C, put the hot material into the cold pot and continue stirring at a low speed. When the temperature drops to 30°C, it can be discharged into the storage barrel; The mixed mold material is granulated through a ...

Embodiment 2

[0032] See accompanying drawing 2, a kind of square wood-plastic foaming, steel pipe combined pipe material, according to thermal transfer hot stamping foil (1), wood-plastic foam pipe material (2), the inner wall is evenly distributed with 4 triangular reinforcing ribs (3 ), steel tubing (4) is located at the structure in the inner circumference of the top of the reinforcing rib (3).

[0033] Its manufacturing method: according to the material composition ratio (calculated by weight percentage) of the wood-plastic foam pipe, surface treatment is carried out; the crop straw straw fiber is crushed into 80-100 mesh powder, and the measurement is carried out according to the above formula. Put the materials, additives and fillers into the high-speed mixer, stir at high speed, fully mix, heat up, when the temperature rises to 75°C, put the hot materials into the cold pot, continue stirring at low speed, and discharge the materials when the temperature drops to 30°C to the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com