DC electric machine

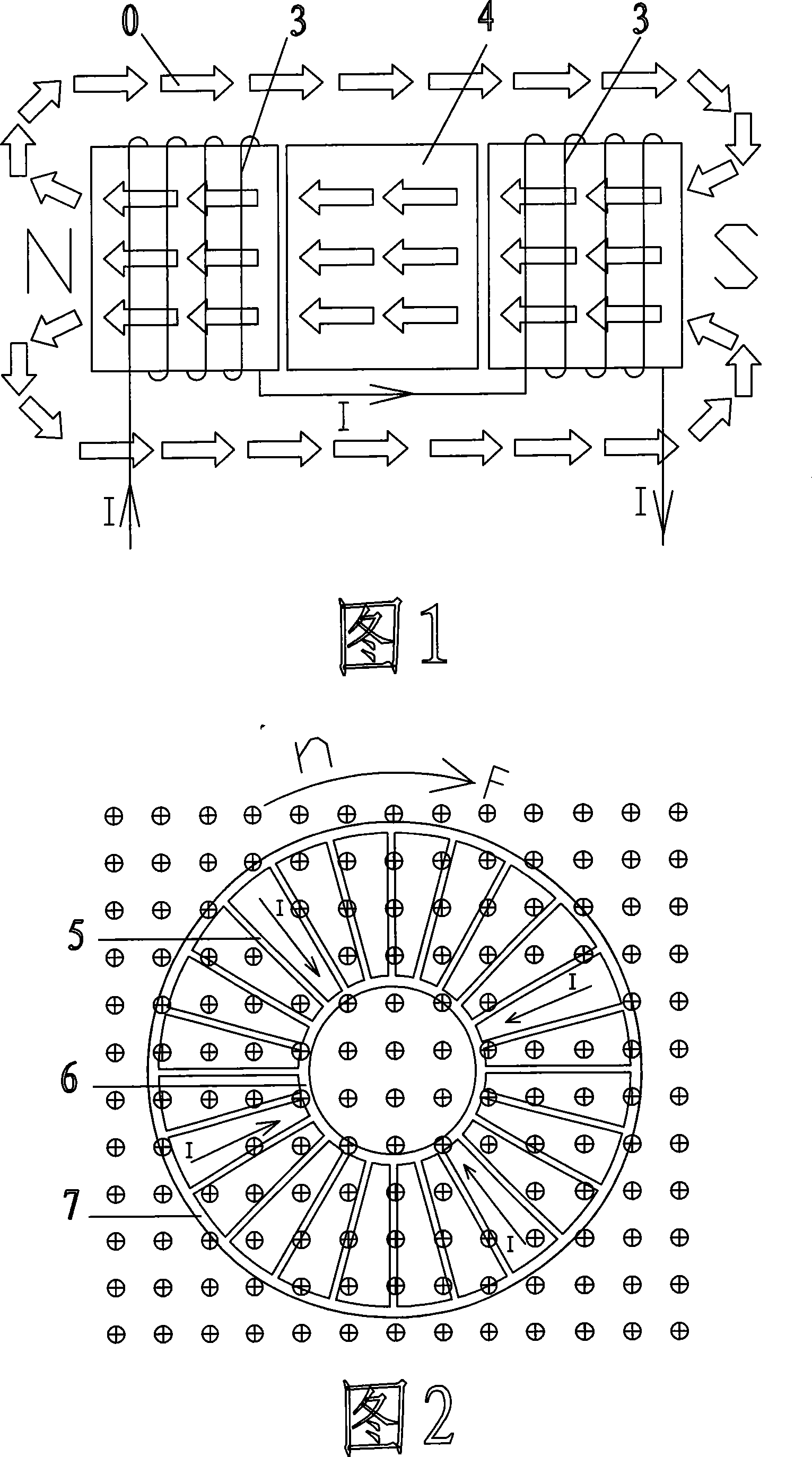

A technology of DC motors and rotors, applied in the direction of electrical components, etc., can solve the problems of complex manufacturing of DC motors, restrictions on the application of DC motors, and persistent difficulties of DC motors, and achieve the effects of less magnetic flux leakage, compact size, and easy manufacturing and processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

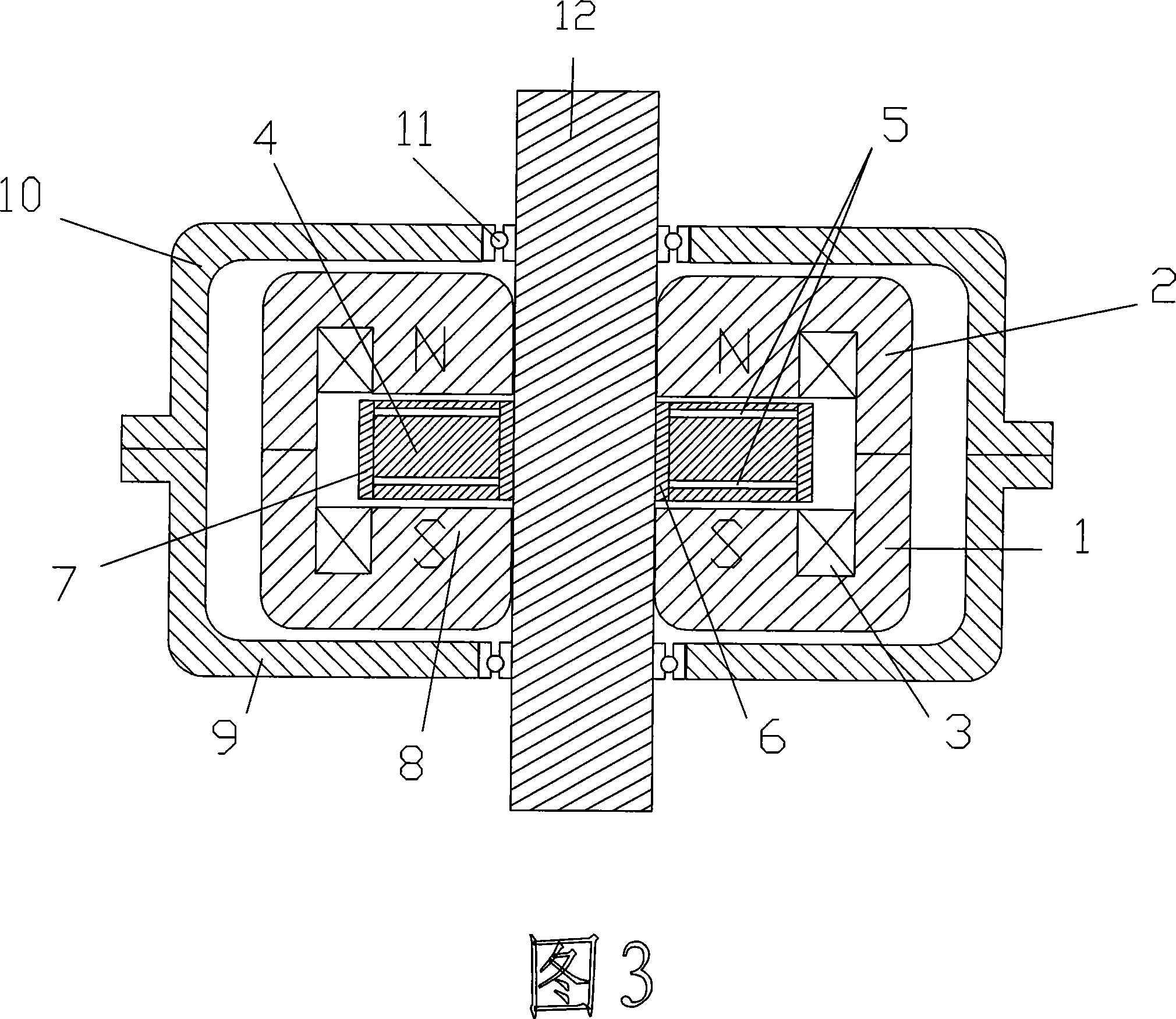

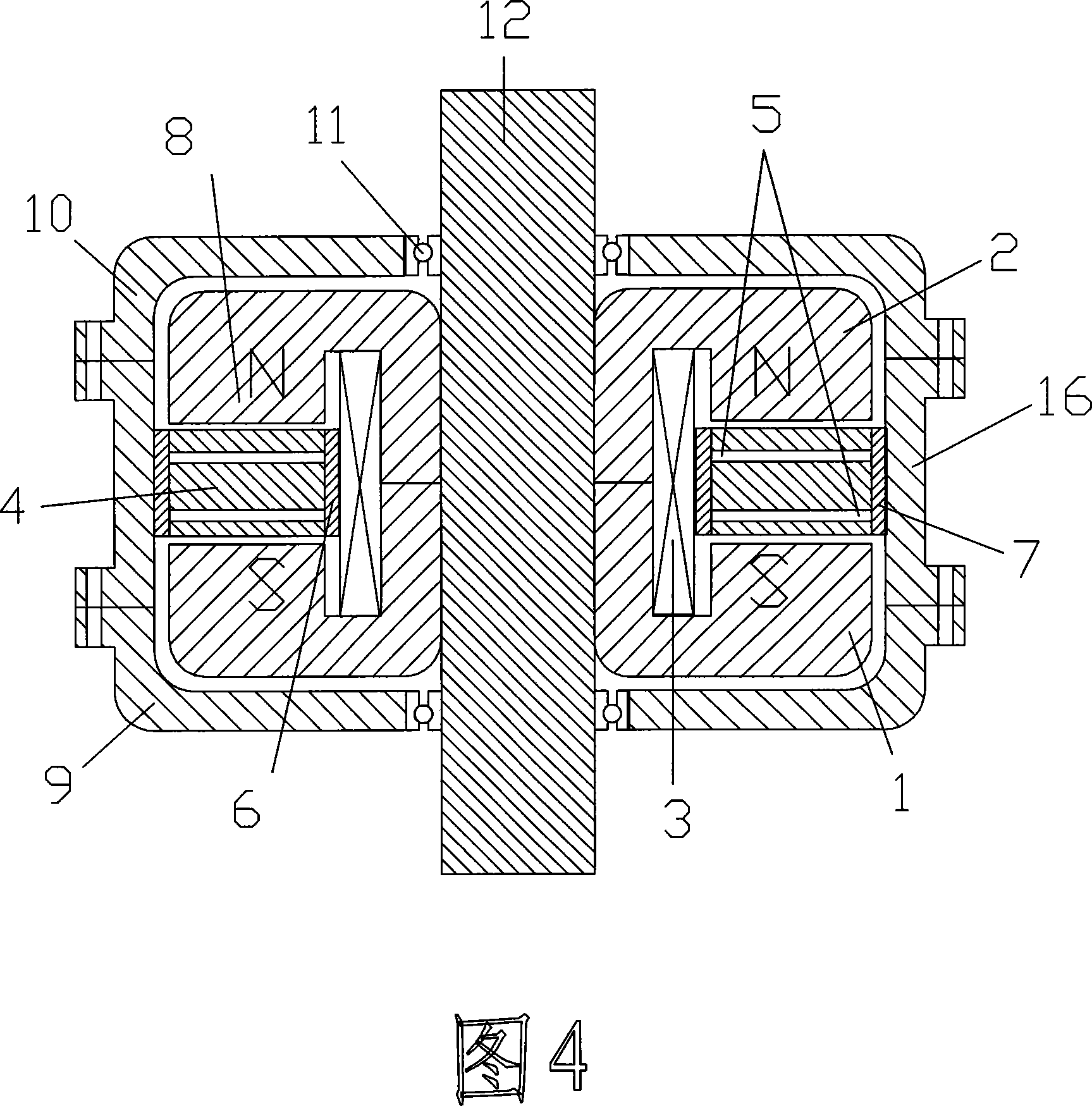

[0022] The DC motor of the present invention is different from ordinary motors in manufacture. Its key components, the rotor and the stator, are made of strip-shaped silicon steel sheets and are automatically completed by computer control on the iron core punching and coiling machine. Before that, open a set of molds for the rotor, and install the molds on the iron core punching and coiling machine. After the rotor and the stator are made, the front stator core (1) and the rear stator core (2) are put together again. The stator coils (3) are wound in one direction and are respectively mounted on the circular magnetic poles (8) of the front stator core (1) and the rear stator core (2). Front end cover (9), rear end cover (10) and support all are cast by pig iron or aluminum alloy. After forming, it can be processed on the machine tool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com