Electronic device and heat radiating module

A heat dissipation module and electronic device technology, which is applied in the direction of circuits, electrical components, electric solid devices, etc., can solve the problems of unable to dissipate heat from FB-DIMM, reduced airflow intensity, limited internal space of the host, etc., and achieve the best heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

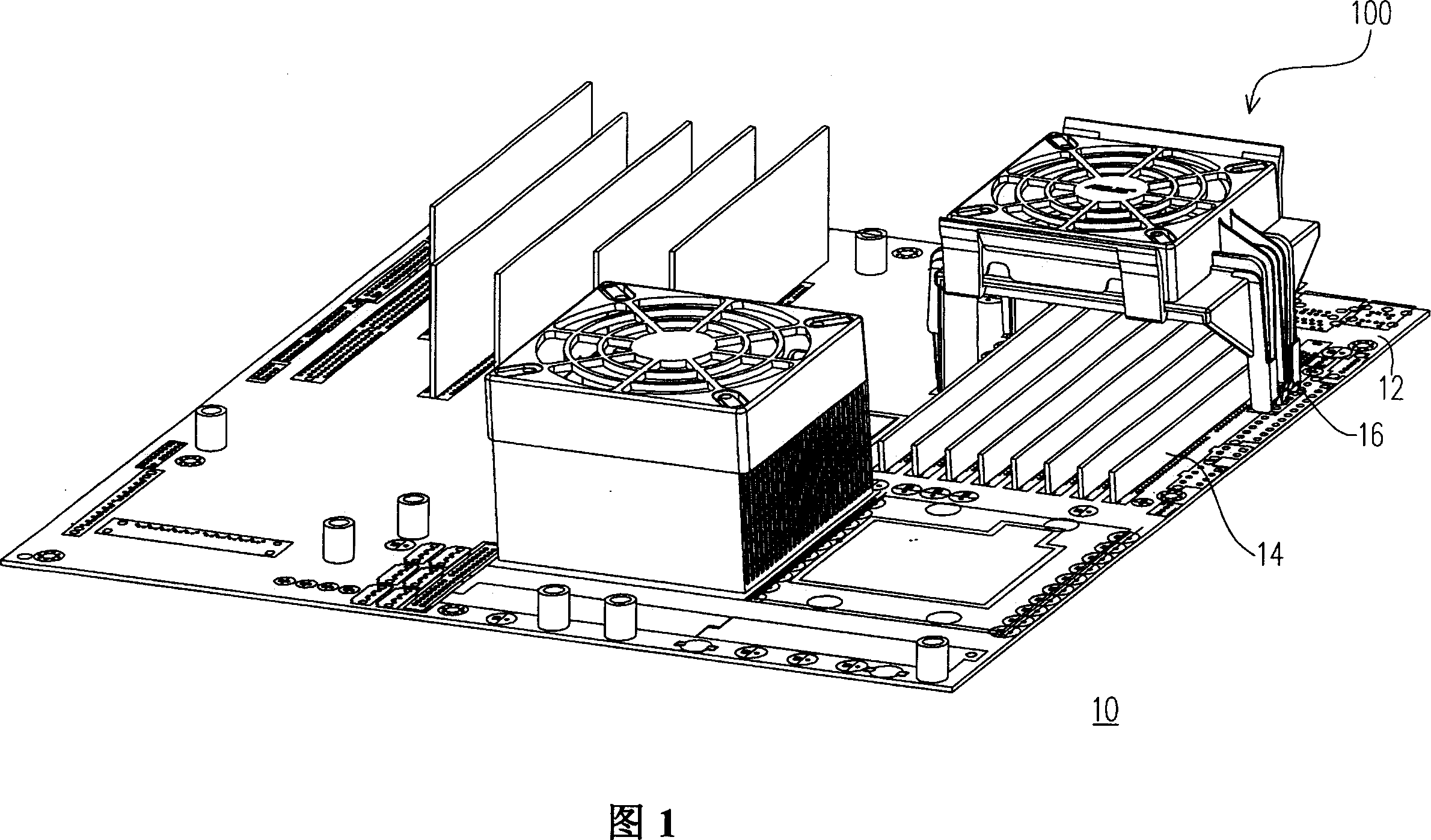

[0055]FIG. 1 is a schematic diagram of a heat dissipation module 100 assembled in an electronic device 10 according to a preferred embodiment of the present invention. Please refer to FIG. 1 , the heat dissipation module 100 of this embodiment is suitable for being assembled on the circuit board 12 of the electronic device 10 to dissipate heat from the heat source 14 on the circuit board 12 , wherein the heat dissipation module 100 is fixed around the heat source 14 A plurality of engaging holes 16 are provided for assembling on the circuit board 12 .

[0056] In this embodiment, the electronic device 10 is a server. In other embodiments, the electronic device 10 may be a 2U disk array (RAID) device or a computer device host. In addition, in this embodiment, the heat source 14 is a plurality of memory modules, and these memory modules are preferably fully buffered memory modules (FB-DIMMs). In other embodiments, the heat source 14 can also be a North Bridge chip, Graphics chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com