Physical method for drawing pattern on tropism silicon steel surface

A technology for oriented silicon steel and the surface of workpieces, which is applied in the fields of technology and decorative art for producing decorative surface effects, can solve problems such as surface damage of metal workpieces, and achieve the effects of reducing stress, strong three-dimensional effect, and preventing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

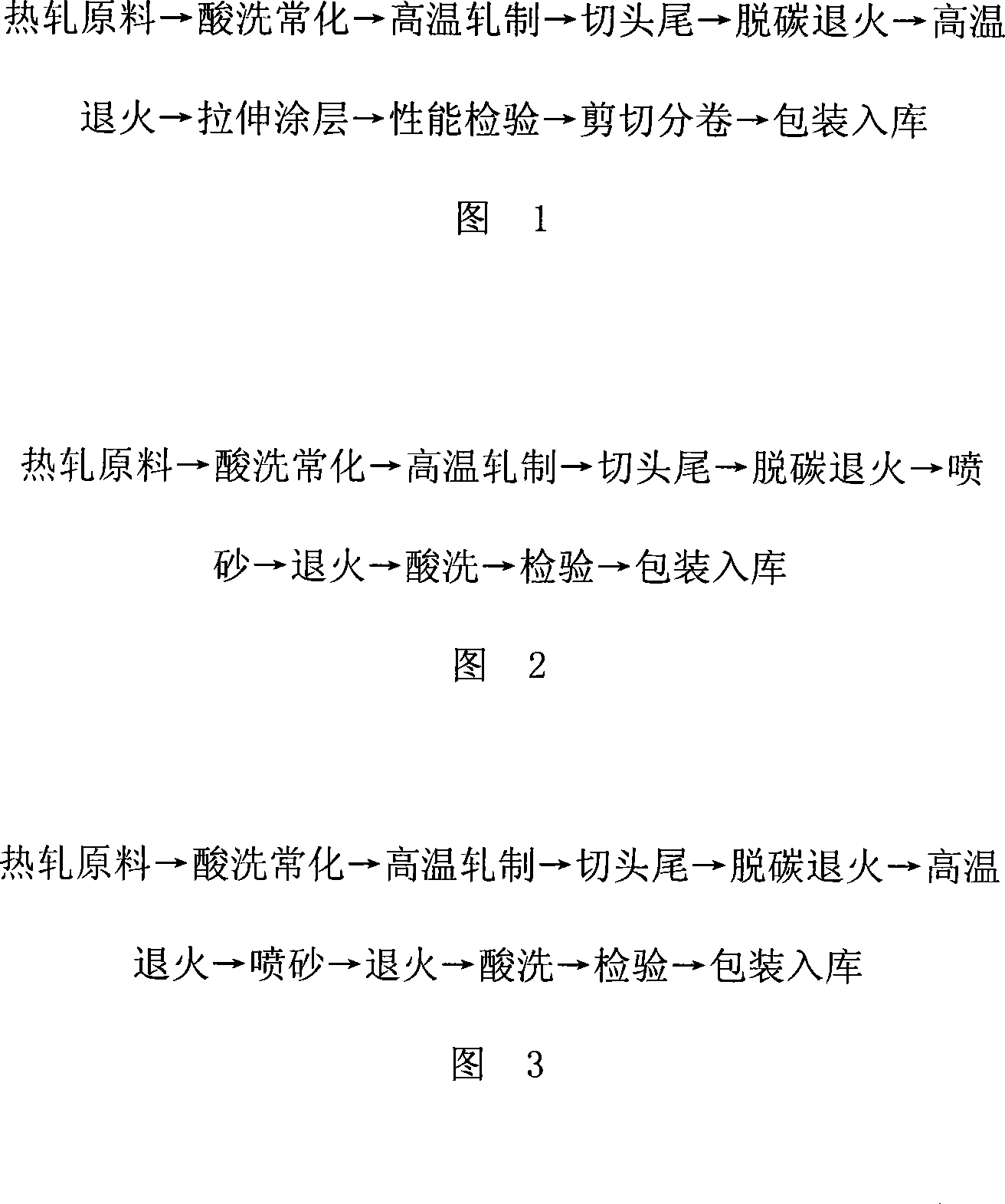

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 of the method of the present invention comprises the following steps:

[0036] (1) According to the required drawing pattern, use a sandblasting machine to blast the patterned parts on the surface of the decarburized and annealed oriented silicon steel workpiece, and then apply a release agent on the surface of the workpiece.

[0037] The above annealed oriented silicon steel workpiece is a decarburized annealed oriented silicon steel workpiece.

[0038] The weight percentage ratio of each component of the release agent is: MgO 5%, TiO 2 5%, and the rest is deionized water. The thickness of the release agent coating is 0.5 μm.

[0039] Sandblasting is sandblasting with corundum. The sandblasting machine is mainly composed of a gas cylinder, a sand storage box, a nozzle and a workpiece moving platform. It uses compressed air or inert gas to drive the emery to the surface of the workpiece, and the emery passes through the sand storage box. To the sandblas...

Embodiment 3

[0050] Embodiment 3 of the physical method for drawing patterns on the surface of an oriented silicon steel workpiece according to the present invention is a physical method for drawing a pattern on the surface of a high magnetic induction oriented silicon steel workpiece, which includes the following steps:

[0051] (1) A step of sandblasting the surface of the annealed grain-oriented silicon steel workpiece according to the required drawing pattern.

[0052] Specifically: direct sandblasting on the patterned parts on the surface of the workpiece. The sandblasting is made of corundum, the pressure of the nitrogen cylinder is 0.3Mpa, the distance between the nozzle and the sample is 40mm, and the particle size of the corundum is 20 mesh. Then apply a release agent, the ratio of the release agent is the usual coating in this field, and the thickness of the coating is 0.1 μm.

[0053] The above annealed oriented silicon steel workpiece is an oriented silicon steel workpiece subj...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com