Biochip hybridization procedure optimization control method and apparatus employing the method

A biochip and chip technology, applied in biochemical equipment and methods, biochemical cleaning devices, microbial measurement/inspection, etc., can solve the problems of long reaction time of hybridization solution, small number of hybridization chips, and large operator dependence , to achieve optimization of hybridization process, good vibration effect, friendly keyboard and display interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

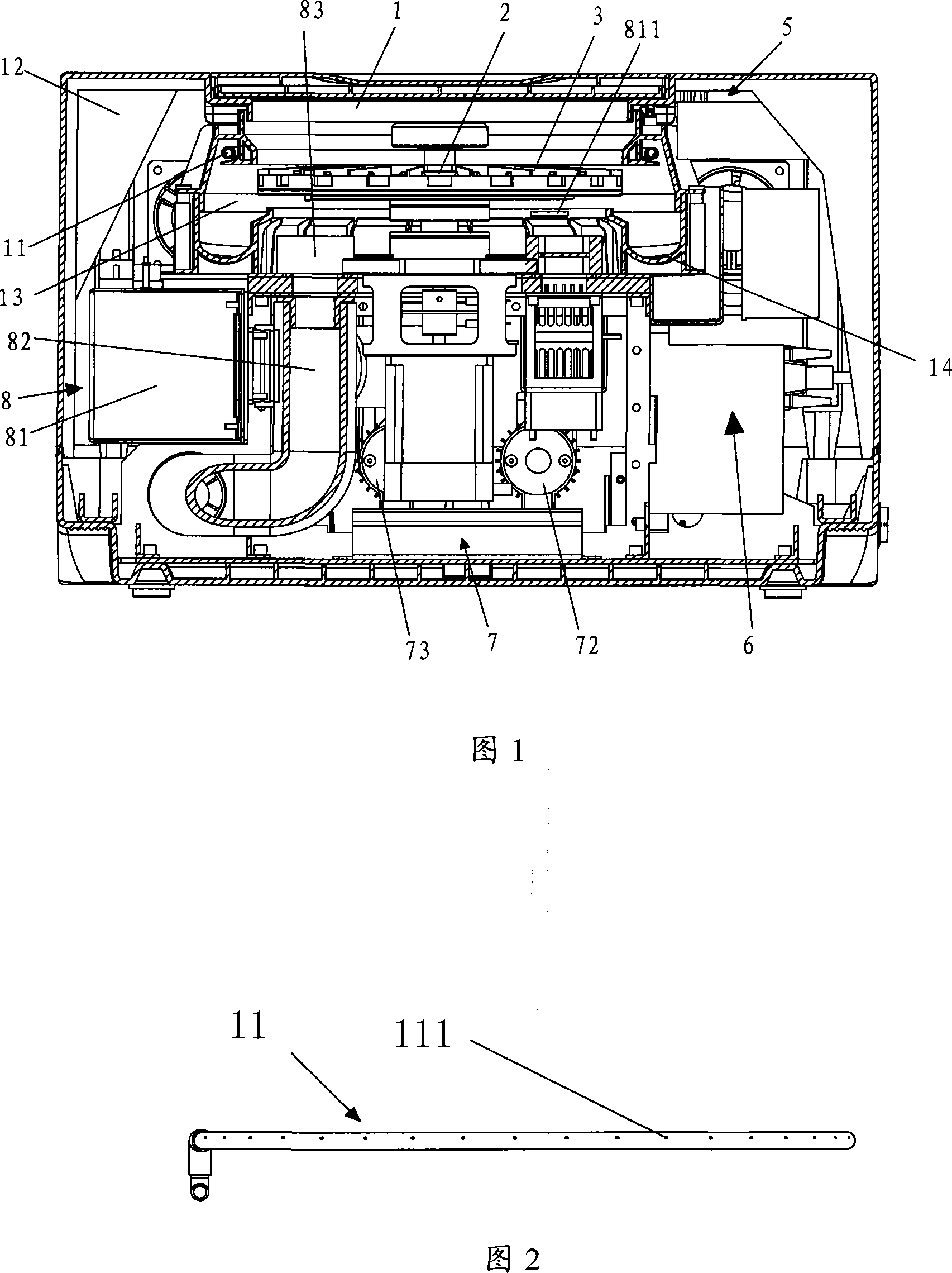

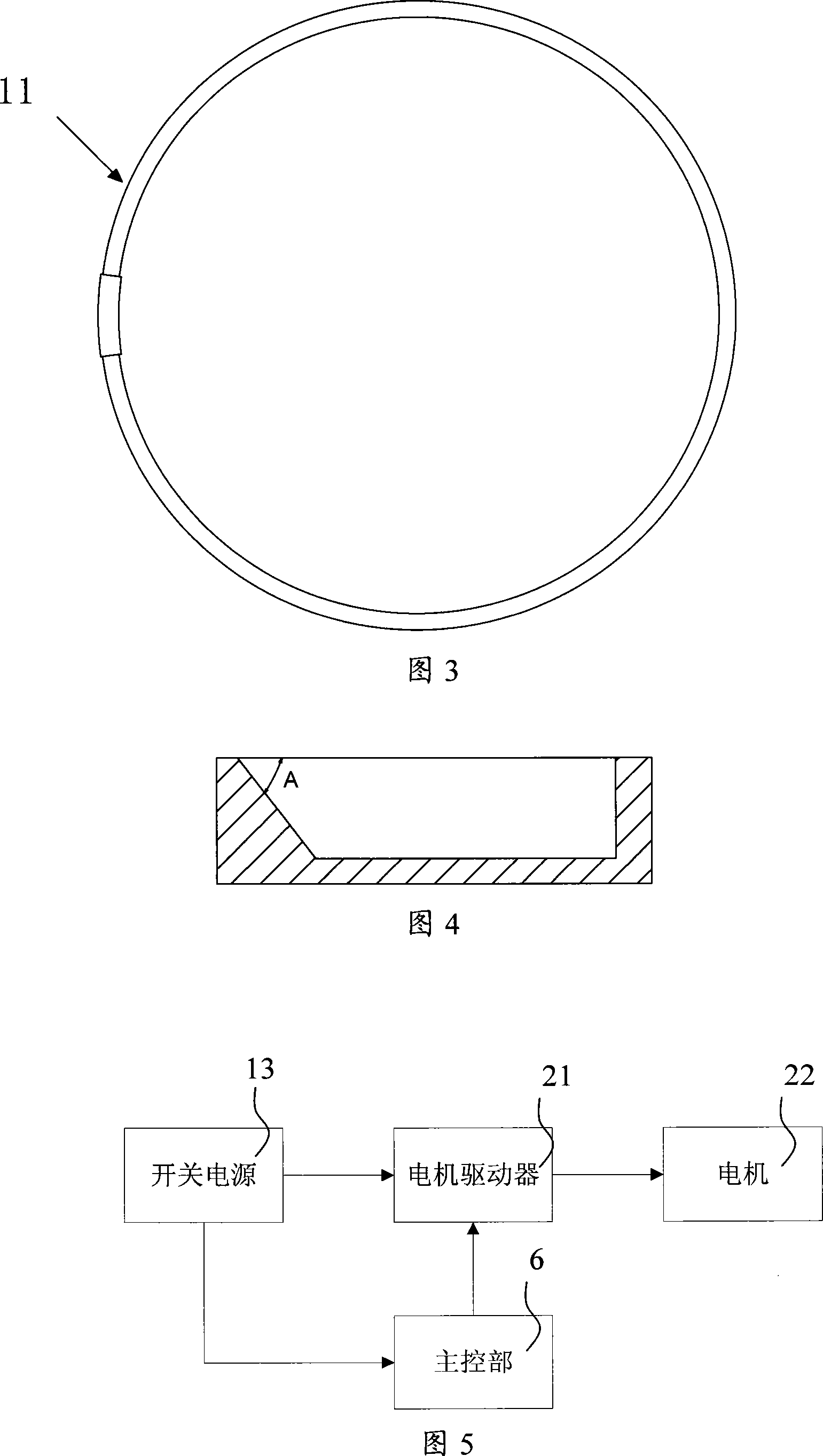

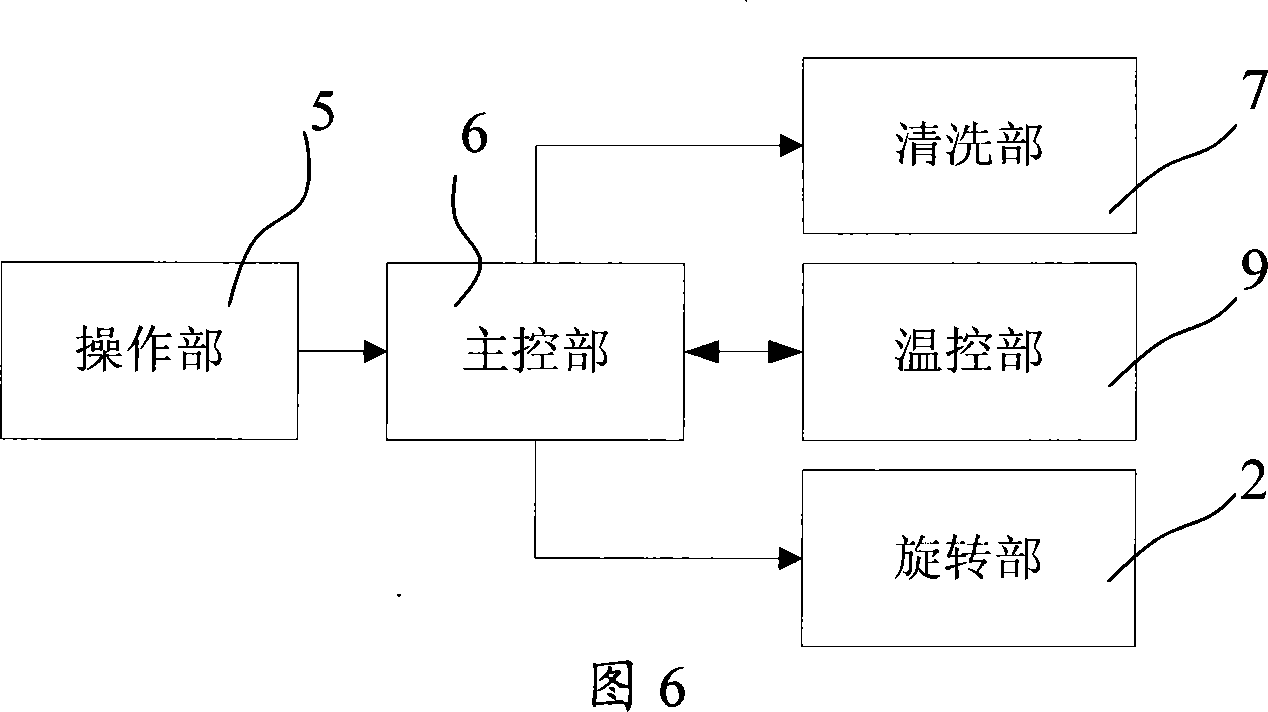

[0031] As shown in FIG. 1 , the present invention includes: a hybridization chamber 1 , a rotating part 2 , a chip carrier 3 , a cleaning tube 4 , an operating part 5 , a main control part 6 , a cleaning part 7 and a casing 12 . The operation part 5 is arranged on the upper part of the casing 12, and it is mainly composed of a keyboard and a display screen. The hybridization chamber 1 is installed in the middle upper position of the casing 12, and the hybridization chamber 1 is provided with a chip carrier 3, on which the chip carrier 3 can place chip cassettes, and the chip carrier 3 can be designed to bear the structure of n chip cassettes, n The optimal choice is 18, and when the number of chip cassettes changes, only the area of the chip carrier 3 needs to be changed. The chip carrier plate 3 is made of plastic, and a metal plate 13 which can control the temperature of the hybridization solution in the chip box is arranged on the bottom thereof, and the metal plate 13 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com