Spring strut bearing

A technology of struts and suspensions, applied in the direction of suspensions, elastic suspensions, shock absorbers, etc., can solve problems such as expensive and complex structures, and achieve a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

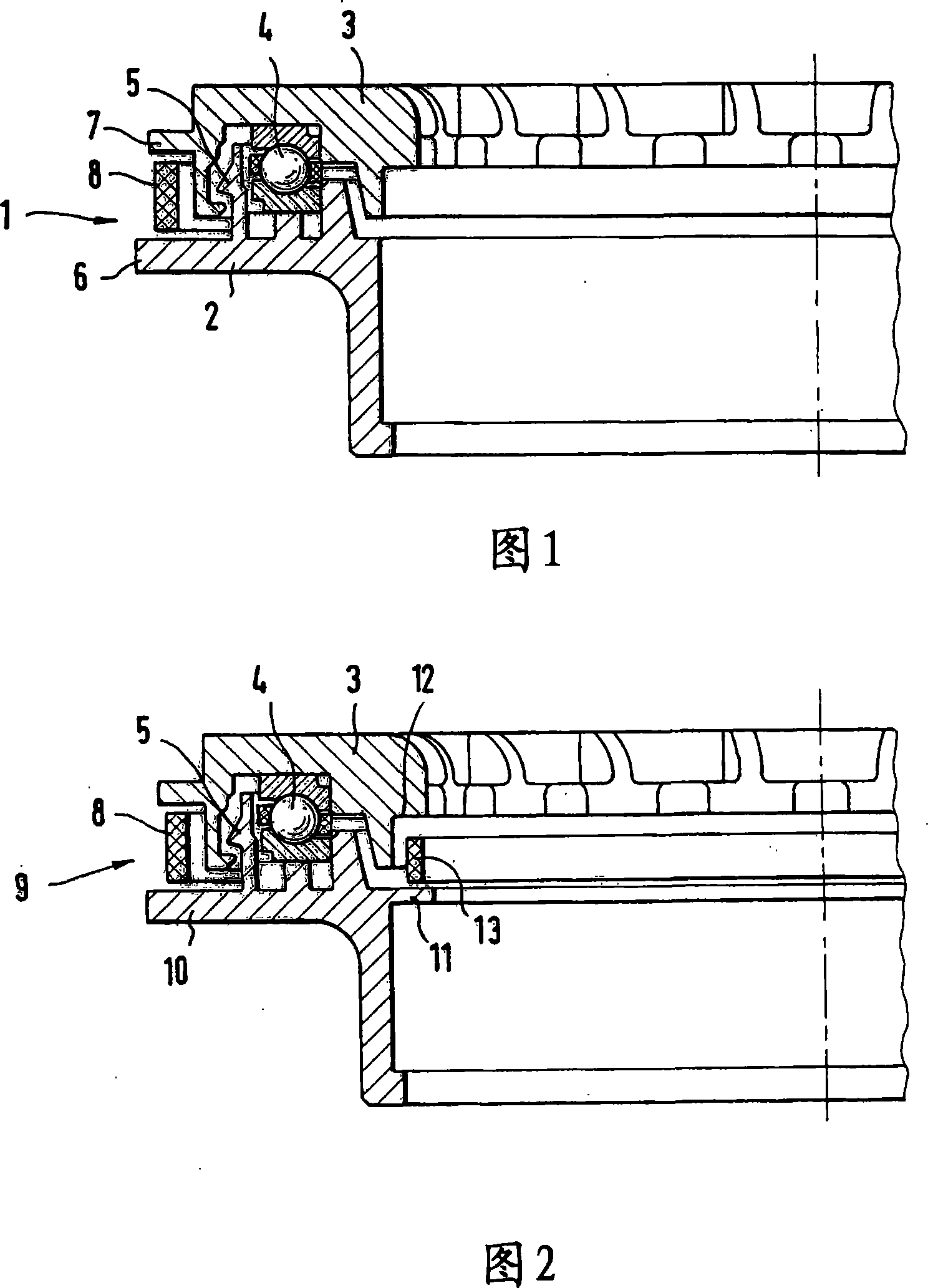

[0017] The suspension strut bearing 1 shown in FIG. 1 basically comprises a housing lower part 2 and a housing upper part 3 which together form a bearing housing in which an axial rolling bearing is accommodated 4. Housing lower part 2 and housing upper part 3 are connected to one another via a snap connection, the two housing parts forming a labyrinth seal 5 which prevents dirt, sand or moisture from penetrating into axial rolling bearing 4 .

[0018] In the region of the parting gap between the housing lower part 2 and the housing upper part 3, the housing parts 2, 3 each have a radial projection 6, 7 on which a sealing ring 8 is held. between.

[0019] The sealing ring 8 has a rectangular cross section and is arranged displaceably between the projections 6 , 7 . When the suspension strut is cleaned with a high-pressure water jet, the sealing ring 8 acts as a splash guard and prevents moisture or dirt from reaching the area of the labyrinth seal 5 or from entering the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com