Partial radiation cooling device

A radiant refrigeration and partial technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of induced discomfort, discomfort, and short service life, so as to maintain comfort, prevent condensation, prevent The effect of increasing the temperature deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

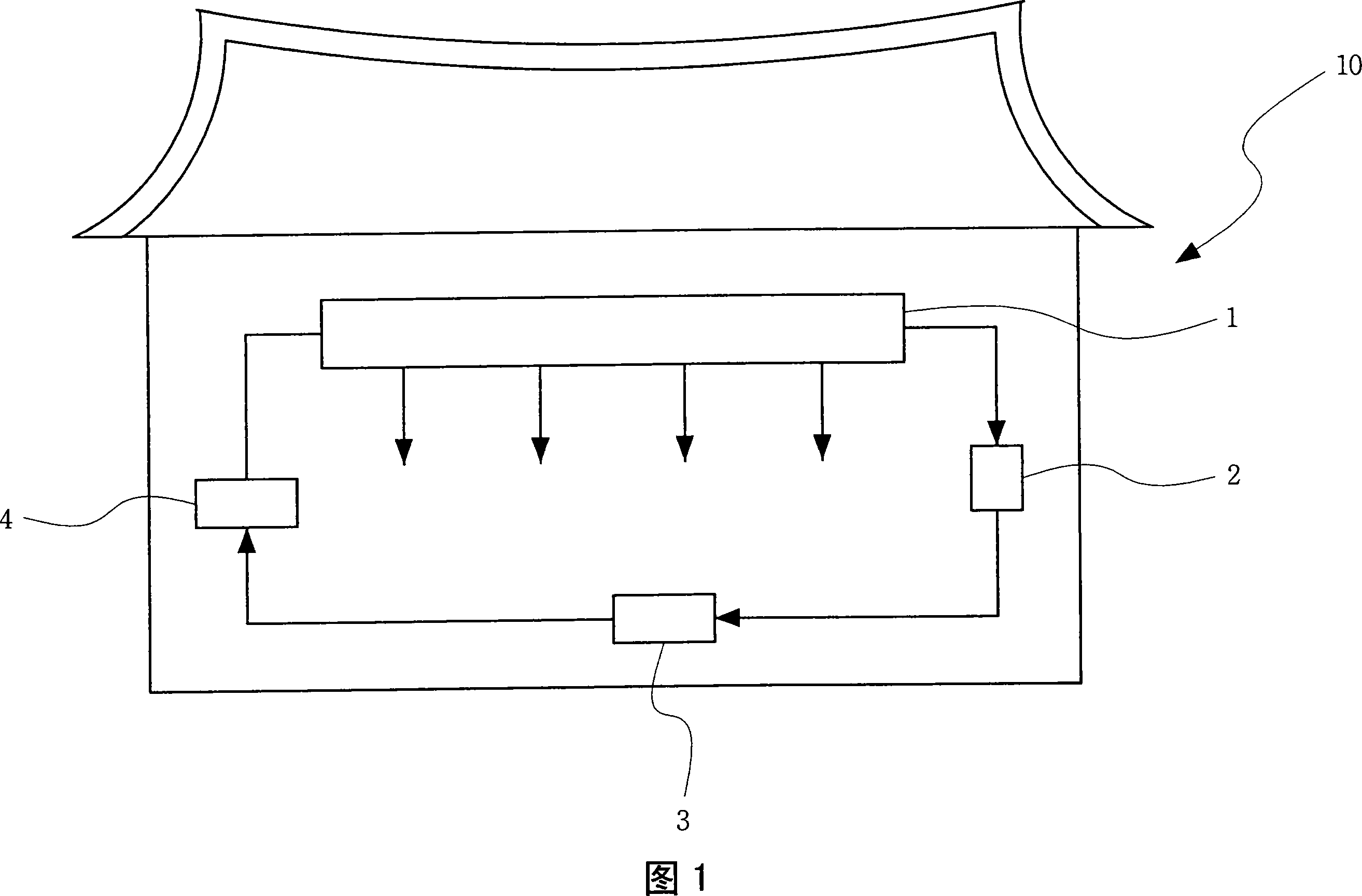

[0042] The local radiant refrigeration device of the present invention can be roughly classified into direct expansion type and indirect cooling type.

[0043] The direct expansion type is a direct cooling method in which the refrigerant is directly evaporated in the pipeline installed inside the radiant panel, and the indirect cooling type is to exchange heat between the refrigerant and the second refrigerant to make it undergo a one-time evaporation process, and then The indirect cooling method is an indirect cooling method in which the second refrigerant cooled by heat exchange is passed through a pipe provided inside the radiant panel to cool it.

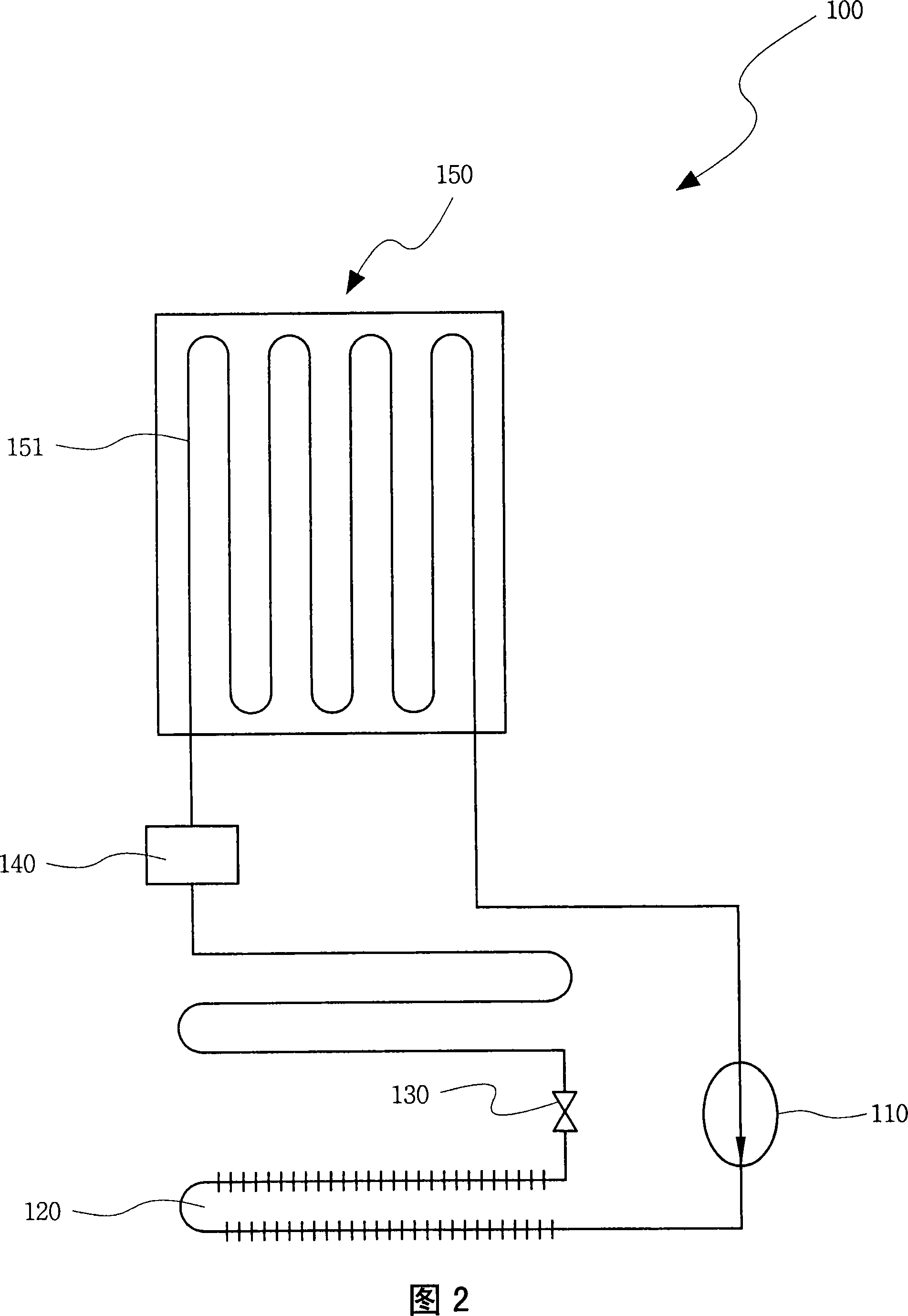

[0044] First, the direct expansion radiant refrigeration device in an embodiment of the present invention is as follows.

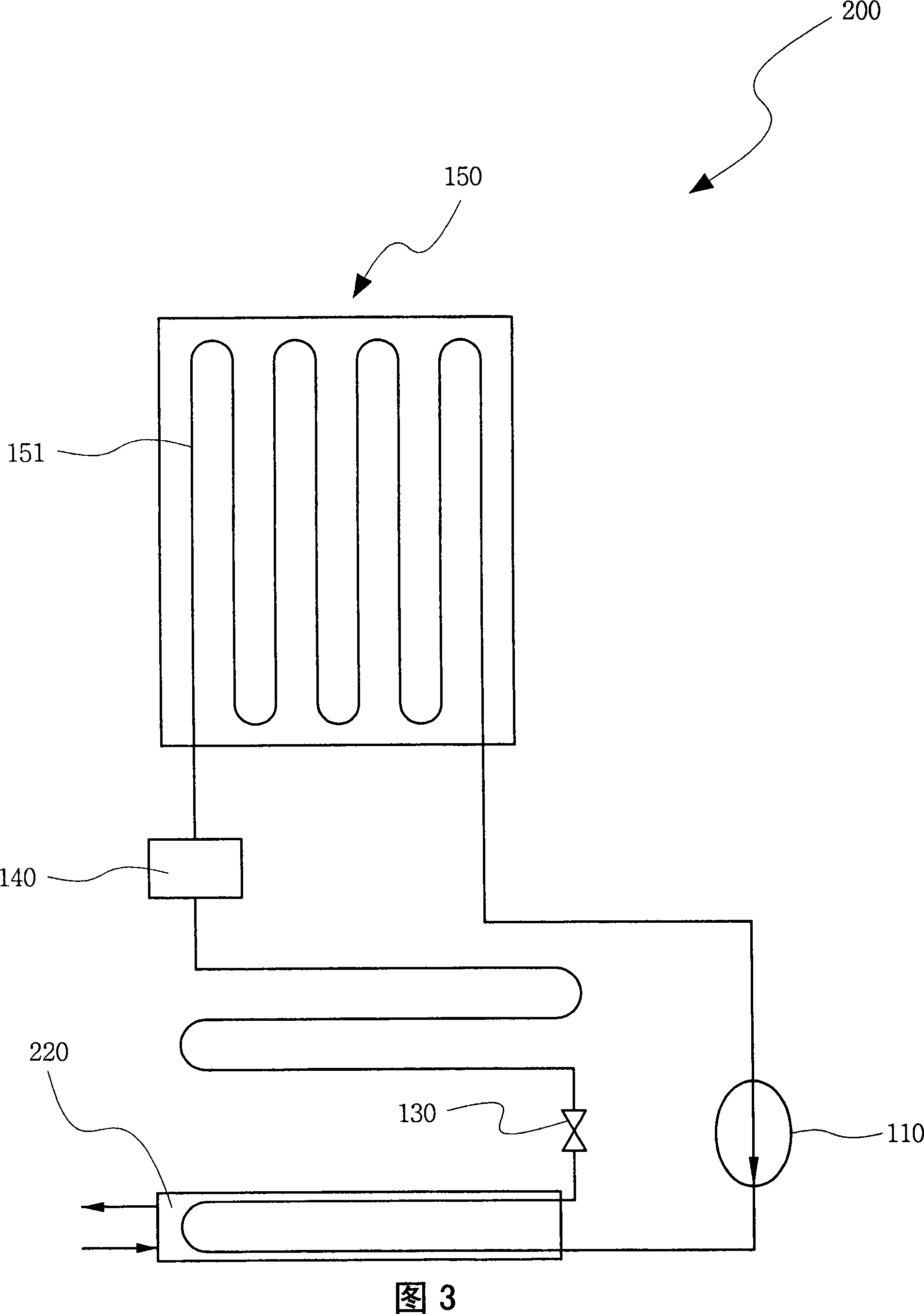

[0045] Fig. 2 is the accompanying drawing that shows the direct expansion type partial radiation refrigeration device of the first embodiment of the present invention, Fig. 3 is the accompanying drawing that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com