Method for carving cutting tool

A technology of knives and blades, applied in the field of chiseling knives, which can solve problems such as waste, short tool life cycle, and inability to continue grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

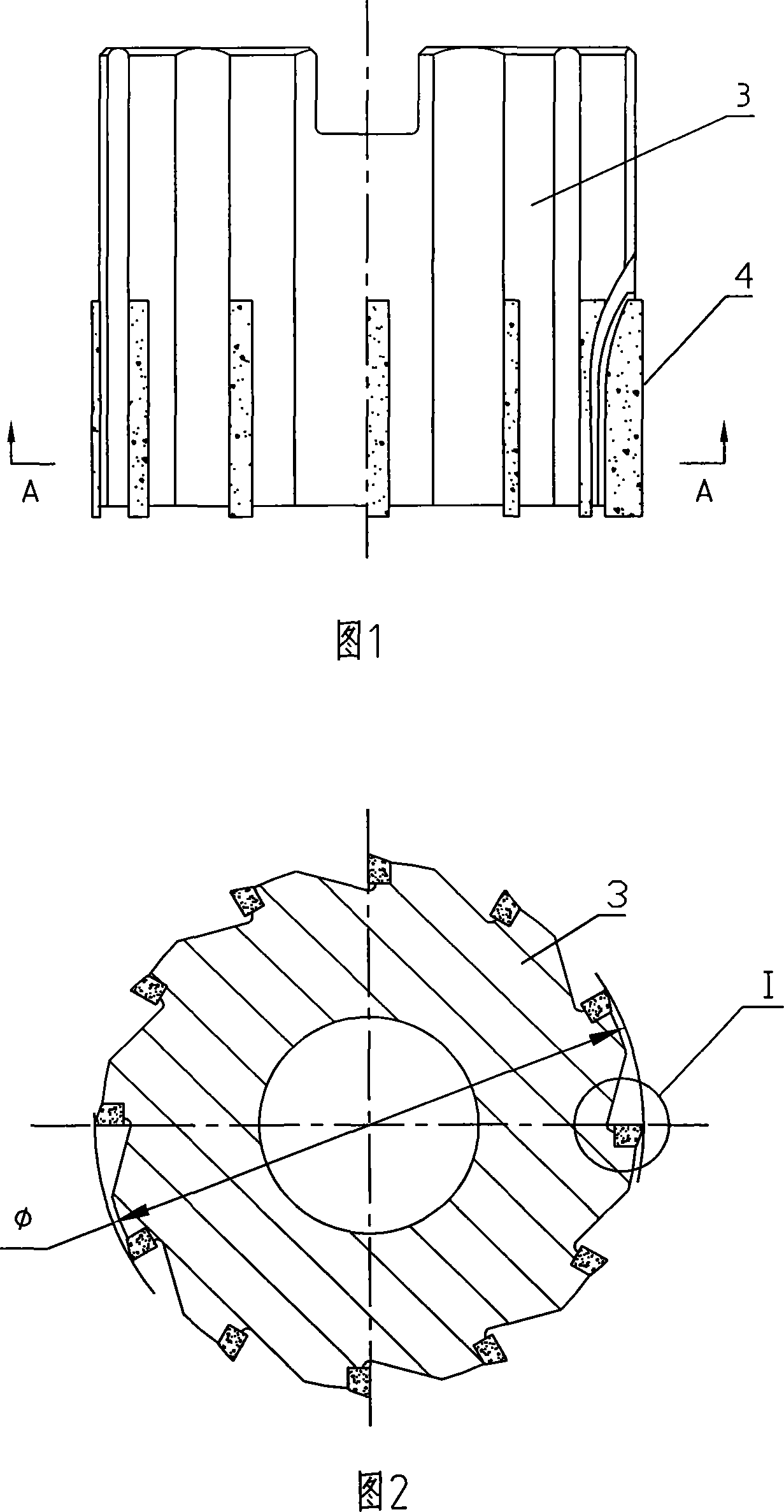

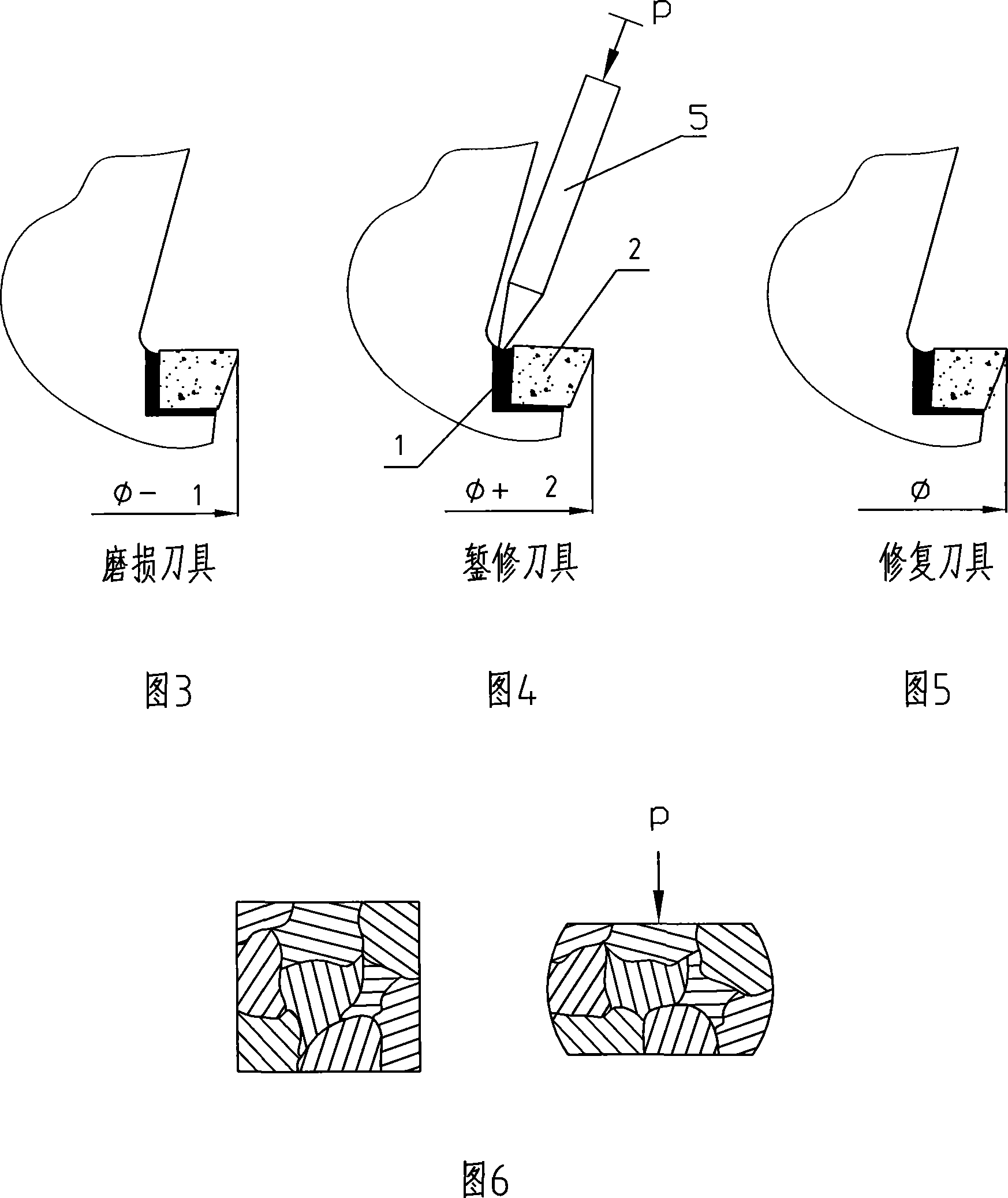

[0017] With reference to accompanying drawing, the method for this chisel repair tool, comprises the following steps:

[0018] (1) use the chisel tool 5 to moderately chisel the copper solder 1 between the cutter body 3 and the blade 2 of the wear cutter, so that a small amount of plastic deformation is produced between the copper solder 1 metal crystal and the amount of plastic deformation. Between 0.03-0.05mm, the blade 2 is slightly moved away from the center of the cutter body 3, the distance from the blade 4 to the center of the cutter 2 is increased, the overall diameter of the cutter is increased, and the diameter of the cutter reduced due to wear is compensated . This chisel tool 5 can adopt common chisel tool grinding to make, and the shape between chisel tool and cutter body 3 and blade 2 is adapted to get final product, also can adopt specially made chisel tool.

[0019] (2) Grinding the outer circle of the tool after chiseling, so that the blade 4 can be restored ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| plastic strain | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com