A method of preparing silicon carbide single crystal by using long crystal component

A technology of silicon carbide single crystal and silicon carbide powder, which is applied in the direction of chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problem of slow atmosphere transmission, difficulty in further increasing the diameter of seed crystal expansion, and failure to improve Ingot quality and other issues, to improve the diameter size and crystal quality, reduce the generation of carbon inclusions, and ensure the effect of crystal growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

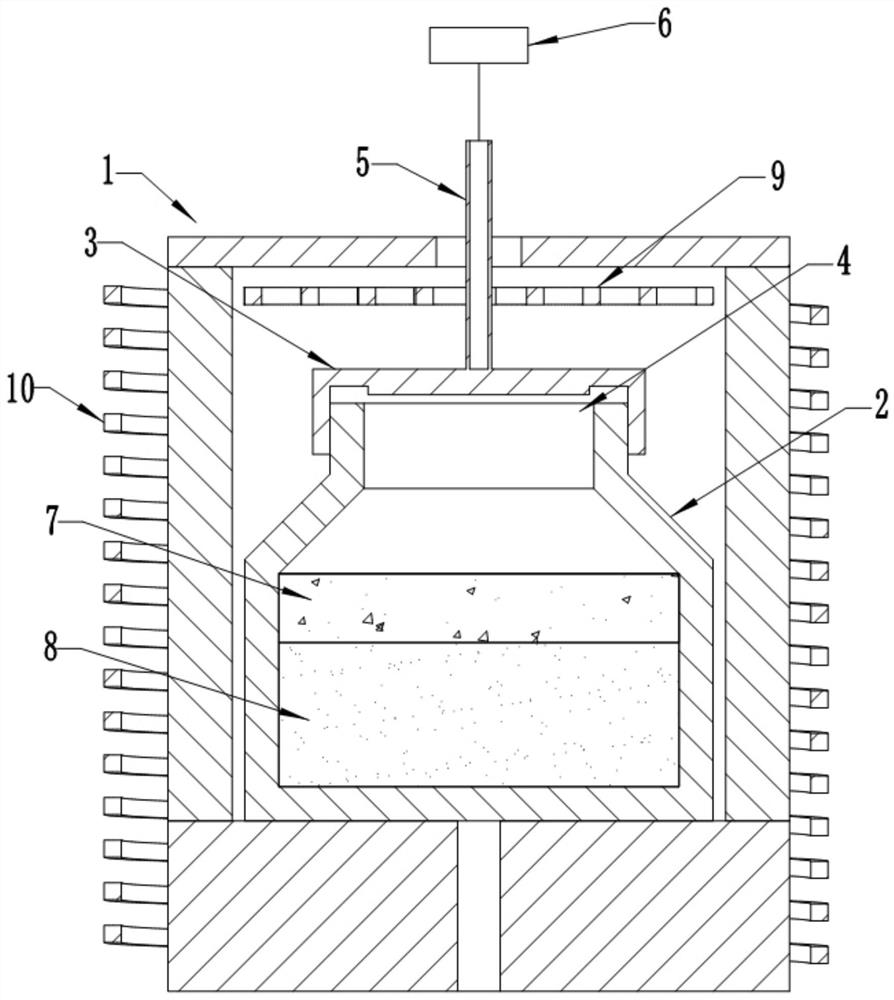

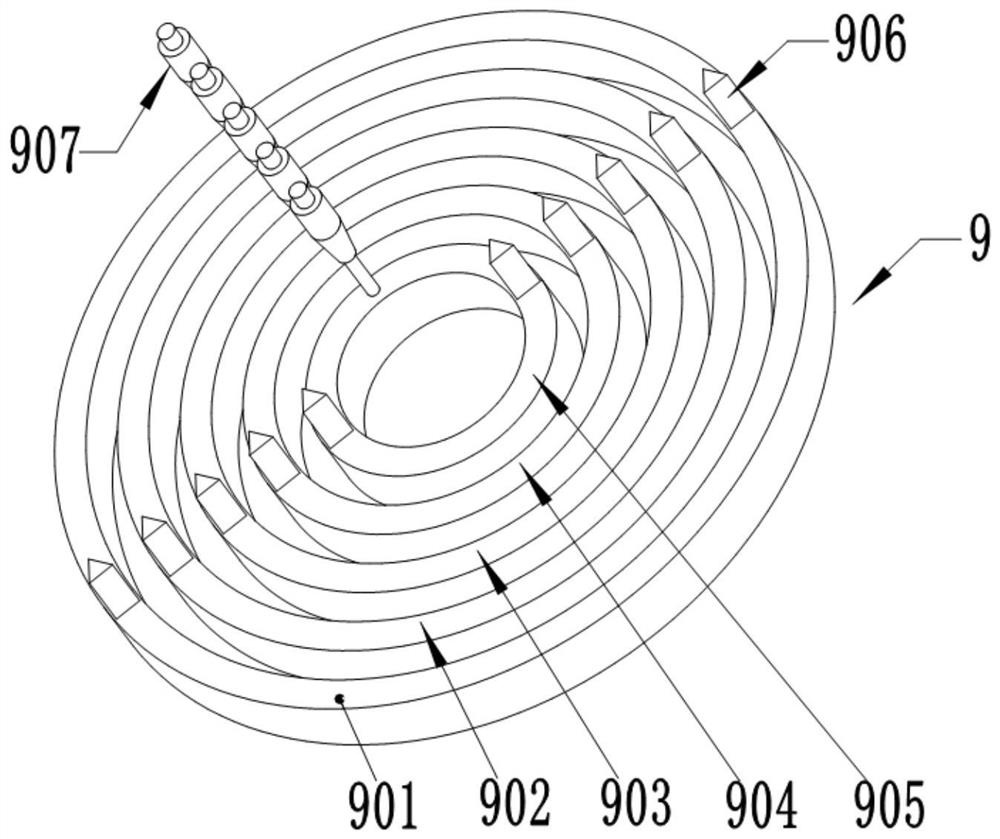

[0070] This embodiment provides a method for preparing a high-quality silicon carbide single crystal, the method comprising the following steps:

[0071] Step 1: Mix silicon carbide powder with a particle size of 1000 μm (that is, the second silicon carbide powder, the same below) and carbon powder with a particle size of 1000 μm in a mass ratio of 5:1 to obtain a mixed powder, and then mix the The mixed powder is loaded into the bottom of the crucible and paved, and then a layer of pure silicon carbide powder with a particle size of 300 microns (i.e. the first silicon carbide powder, the same below) is placed on the top of the mixed powder, wherein the mixed powder The mass is 3kg, the mass of pure silicon carbide powder is 1kg, that is, the total mass of crystal growth raw materials is 4kg;

[0072] Step 2: Fix the silicon carbide seed crystal on the inner side of the upper cover of the crucible, adjust the position of the upper cover of the crucible to the lowest position, ...

Embodiment 2

[0080] This embodiment provides a method for preparing a high-quality silicon carbide single crystal, the method comprising the following steps:

[0081] Step 1: Mix silicon carbide powder with a particle size of 800 μm and carbon powder with a particle size of 600 μm evenly in a mass ratio of 5:2 to obtain a mixed powder, then put the mixed powder into the bottom of the crucible and spread it flat, then Place a layer of pure silicon carbide powder with a particle size of 200 microns above the mixed powder, wherein the quality of the mixed powder is 3.5kg, the quality of the pure silicon carbide powder is 1kg, that is, the total mass of the crystal growth raw material is 4.5kg ;

[0082] Step 2: Fix the silicon carbide seed crystal on the inner side of the upper cover of the crucible, adjust the position of the upper cover of the crucible to the lowest position, merge it with the crucible, and assemble the crystal growth furnace completely;

[0083] Step 3: Turn on the air pu...

Embodiment 3

[0090] This embodiment provides a method for preparing a high-quality silicon carbide single crystal, the method comprising the following steps:

[0091] Step 1: Mix silicon carbide powder with a particle size of 800 μm and carbon powder with a particle size of 800 μm in a mass ratio of 6:1 to obtain a mixed powder, then put the mixed powder into the bottom of the crucible and spread it flat, then Place a layer of pure silicon carbide powder with a particle size of 400 microns above the mixed powder, wherein the quality of the mixed powder is 3.5kg, the quality of the pure silicon carbide powder is 1kg, that is, the total mass of the crystal growth raw material is 4.5kg ;

[0092] Step 2: Fix the silicon carbide seed crystal on the inner side of the upper cover of the crucible, adjust the position of the upper cover of the crucible to the lowest position, merge it with the crucible, and assemble the crystal growth furnace completely;

[0093] Step 3: Turn on the exhaust pump,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com