Terminal system

A terminal system, input and output technology, applied in general control systems, control/regulation systems, program control, etc., can solve the problems of complex wiring layout, multi-core cable wiring disconnection, wiring changes, etc., and achieve layout changes. It is easy to realize the effect of improving the number of wiring and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

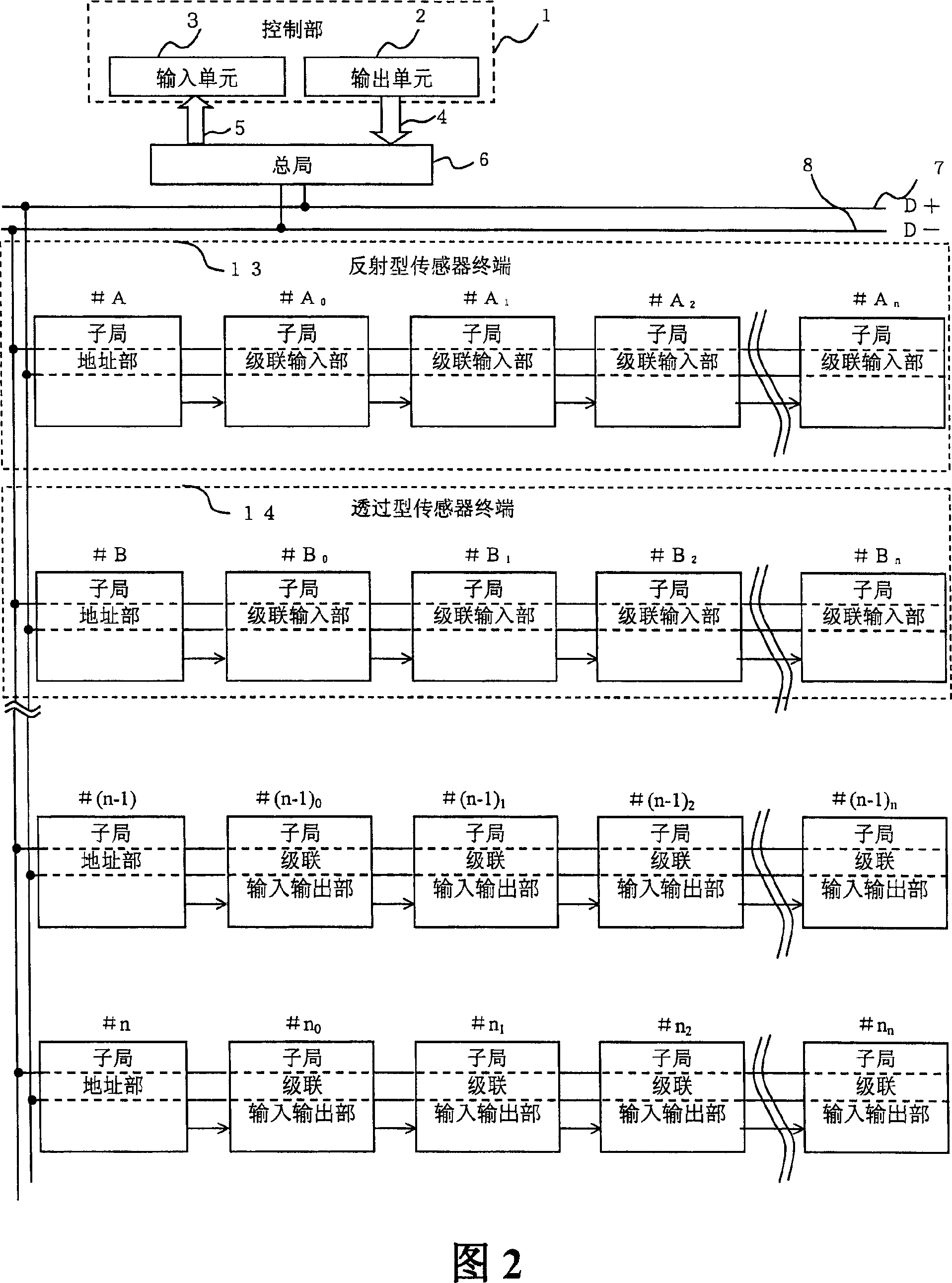

[0146] Embodiments of the present invention will be described with reference to FIGS. 1 to 15 .

[0147] Fig. 1 shows a plurality of input and output systems in the present invention.

[0148]In the I / O system of FIG. 1 , the central office 6 is connected to the control unit that receives and receives input and output information, and is connected to the sub-office address unit 9 through the D+ power overlapping common data signal line 7 and the D- power overlapping common data signal line 8 . The sub-office address part 9 is connected to the sub-office input and output terminal unit 10 with the D+ power supply overlapping common data signal line 7 and the D-power supply overlapping common data signal line 8 as it is, and to a plurality of sub-offices installed on the jacket conduit 12 as sub-offices. The sub-office input-output terminal unit 10 of the office cascade input-output section transmits the cascade mobile signal 11 successively, thus forming an input-output system. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com