Computer aided scheduling model for guiding rhythm of steel making, and continuous casting steel supply

A computer-aided, scheduling model technology, applied in the computer field, can solve problems such as waste of material resources and achieve accurate calculations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Example 1: An example of independent operation of the steelmaking and continuous casting timetable model

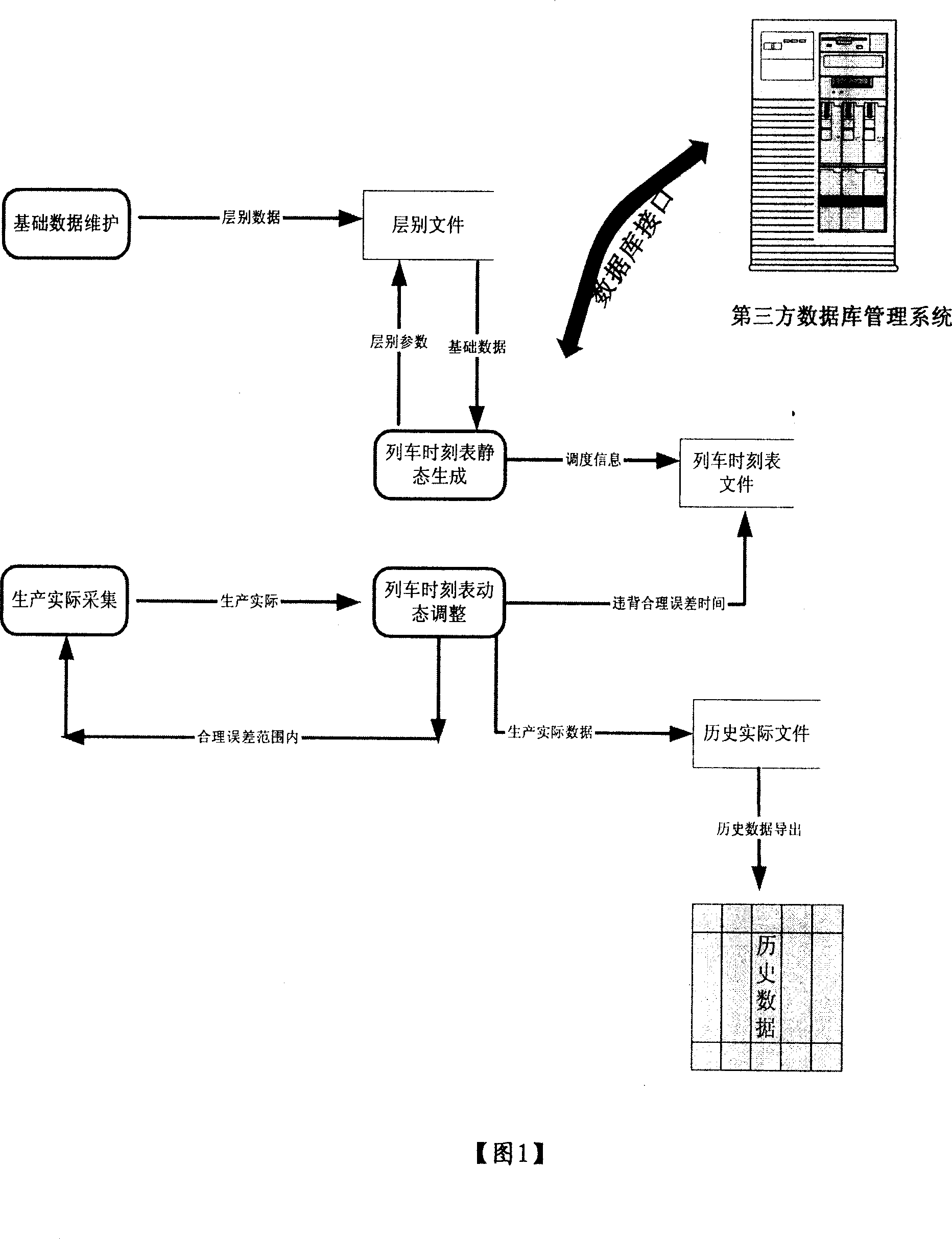

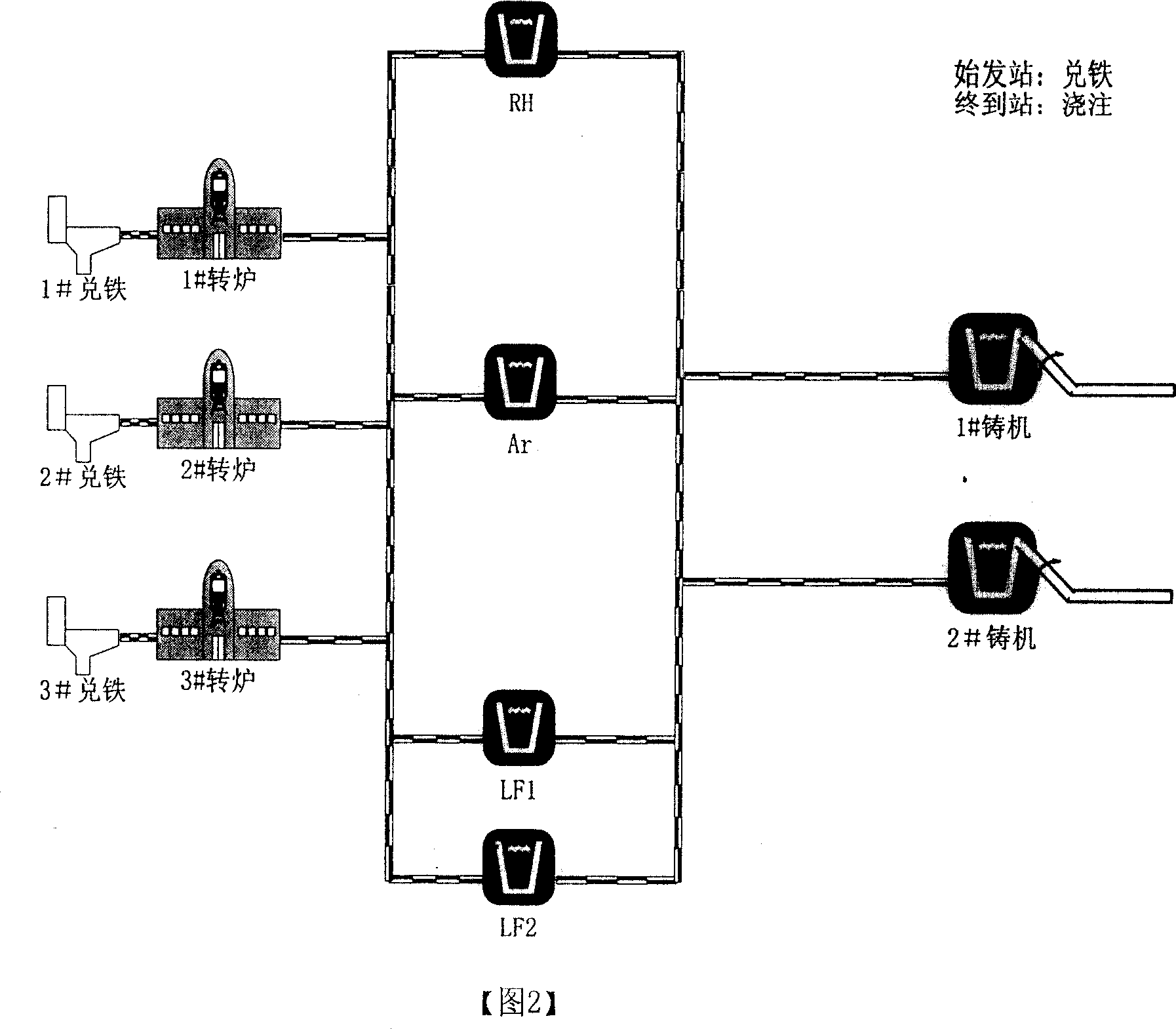

[0072] As shown in Figure 1, the production plant in this example has three converters, 1#, 2#, and 3#, 1 argon blowing station, 2 LF furnaces, 1 RH, and 2 continuous casting machines.

[0073] 1. Basic data layer maintenance

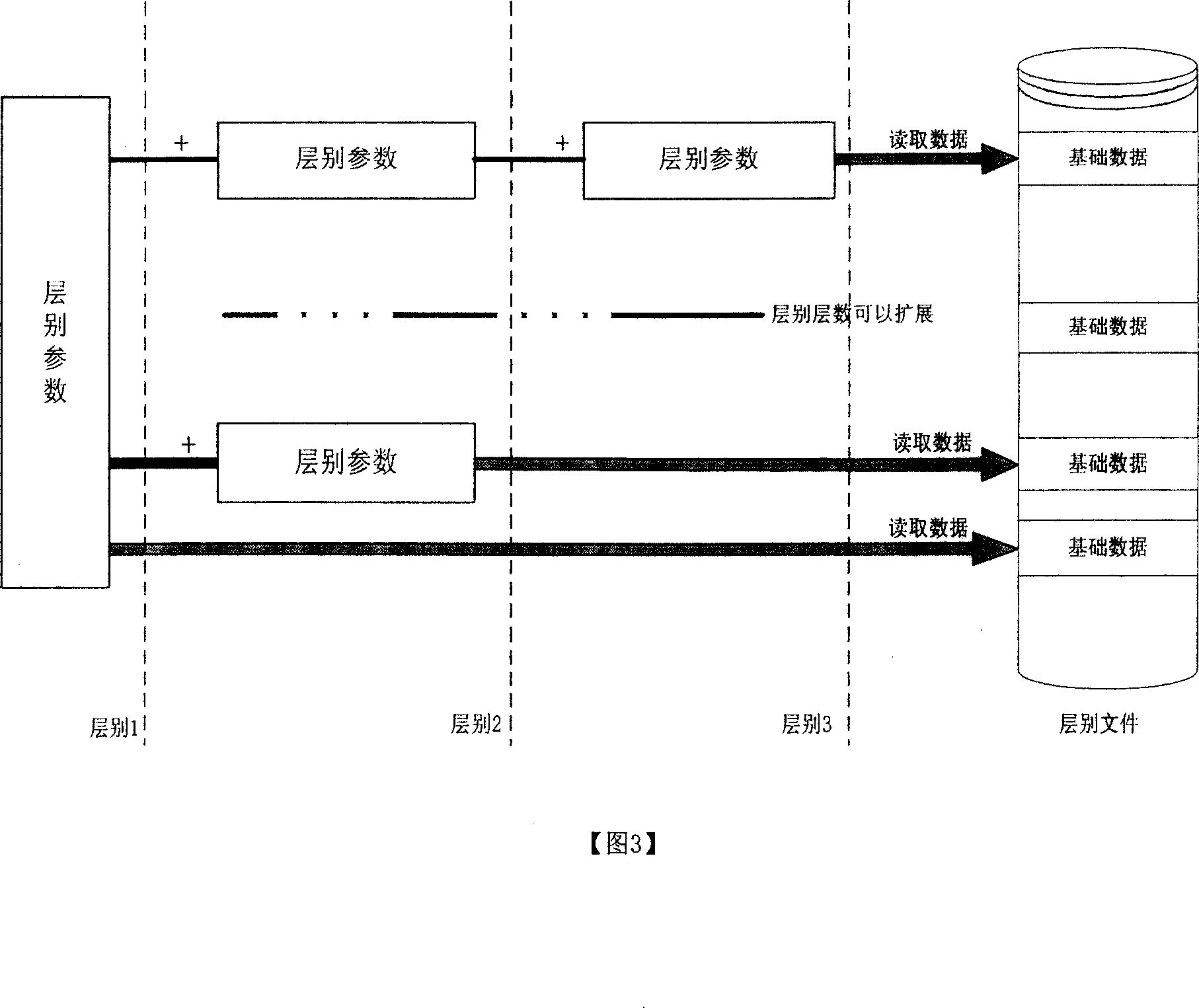

[0074] The user first selects the name of the layered data to be maintained, and then enters the layered parameters needed to extract the layered data, and the system automatically exports the standard layered data to the layered data maintenance interface according to the contents of the layered parameters. Then the user enters and modifies layer data through the layer data maintenance interface. The specific content of the basic data is described in item 2 of the content of the invention in the description.

[0075] For example, in this example, the user requests that the target casting speed of the continuous casting machine need to be ...

Embodiment 2

[0089] Example 2: An example of embedding the timetable model of steelmaking and continuous casting into a third-party system for operation

[0090] As shown in Figures 1 and 2, the production plant in this example has three converters, 1#, 2#, and 3#, 1 argon blowing station, 2 LF furnaces, 1 RH, and 2 continuous casting machines. Complete production planning management system, its relational database is oracle9i, but the third-party system lacks the computer-aided guidance part of steel supply rhythm, the present invention can be embedded in this management system, and realize the scheduling of steelmaking and continuous casting steel supply rhythm automation.

[0091] 1. Embedded in third-party systems

[0092] According to item 6 of the content of the invention in the description:

[0093] 1) Understand that the service name of the oracle9i database in the third-party system is ora, and the server name is steel_server, and use the tools provided by oracle to create a net...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com