Optical element

A technology of optical components and components, applied in the field of optical components, can solve problems such as difficult manufacturing, and achieve the effect of uniform electric field and uniform conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

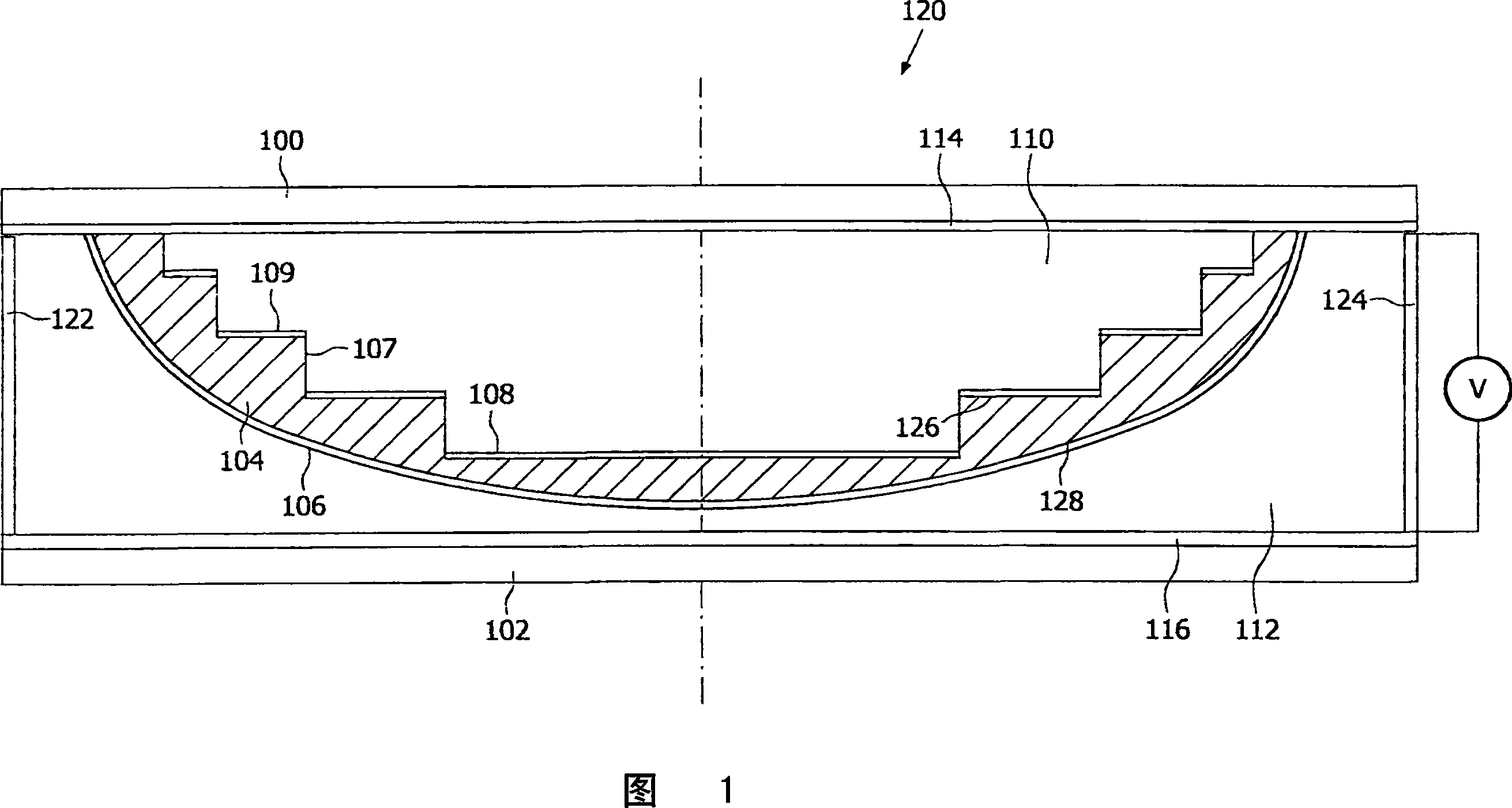

[0018] Fig. 1 is an enlarged cross-sectional view of one embodiment of an optical element according to the present invention. In this embodiment, the optical element 120 includes two transparent plates 100, 102, and two transparent electrodes 114, 116, which are respectively arranged perpendicular to the optical axis indicated by the dashed line. The electrodes are connected to a power supply V and are joined by insulating spacers 122 , 124 . The two electrodes may be formed, for example, of indium tin oxide (ITO) coated glass and are typically applied by evaporation or sputtering on the inner sides of the transparent plates 100, 102. The optical element also comprises a fluid material 104 having a variable refractive index depending on the voltage applied between the electrodes, preferably an AC voltage. In this embodiment, the element is a liquid crystal (LC) lens and the fluid material is a liquid crystal material. The thin layer of material 104 is sandwiched between a fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com