Cigarette package, wrapping paper for cigarette package, and method and machine for manufacturing wrapping paper

A technology for manufacturing equipment and wrapping paper, applied in the directions of wrapping paper, wrapping paper, packaging, etc., can solve the problems of lack of direct decomposability, increased environmental burden of laminated paper, hindering the flavor and smell of smoking articles, etc., and achieves direct decomposability. Excellent, the effect of reducing the burden on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] wrapping paper

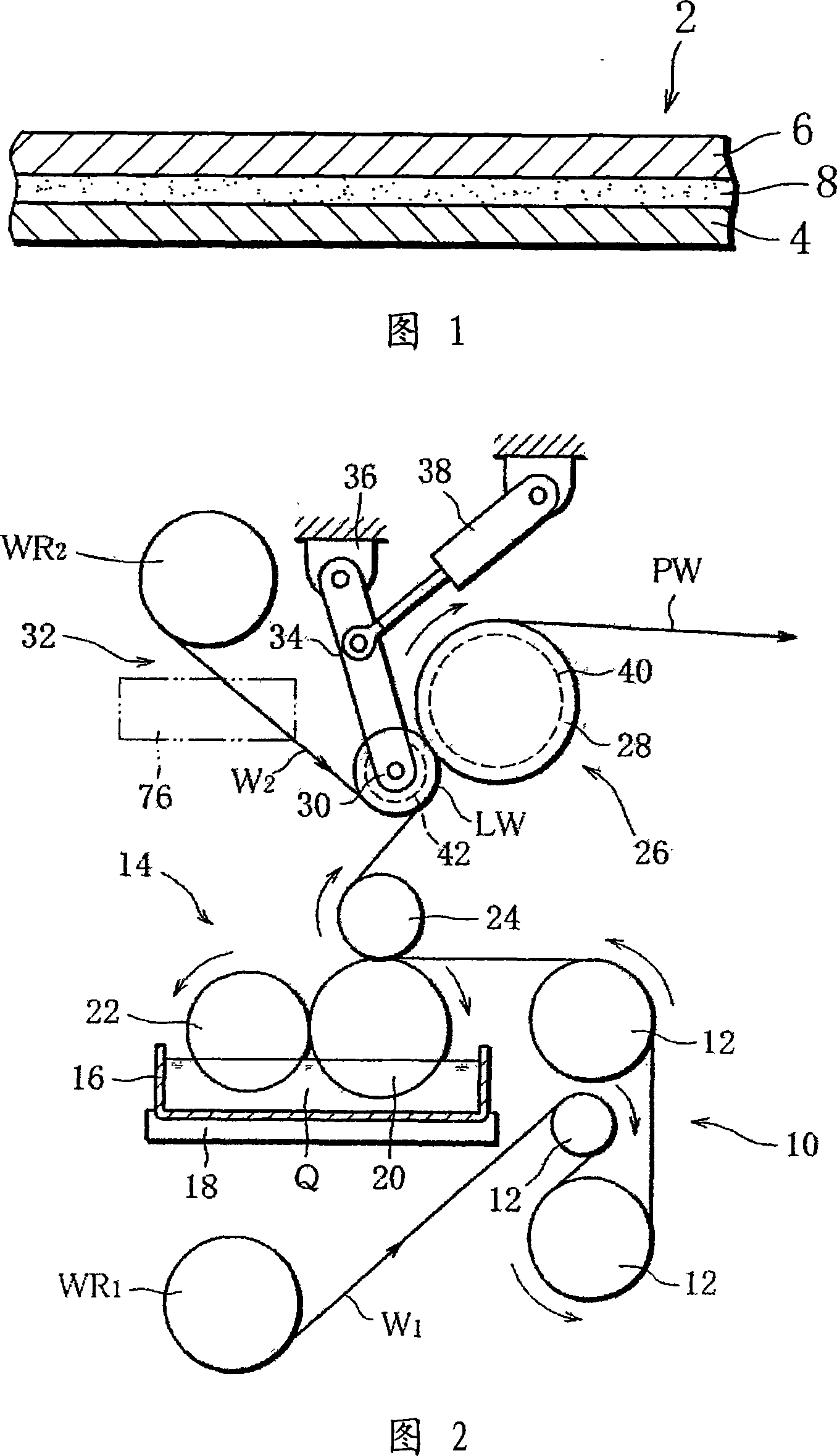

[0030] As shown in FIG. 1, the wrapping paper 2 of one embodiment has a triple structure. The wrapping paper 2 comprises translucent first and second paper layers 4, 6, which respectively form the two sides of the wrapping paper 2. Preferably, both the first and the second paper layer 4, 6 consist, for example, of cellophane. At this time, the weight of cellophane is from 20 to 40g / m 2 range selection, preferably from 25 to 35g / m 2 Select the range, specifically the grammage of the first and second paper layers 4 and 6 is 30.5g / m 2 .

[0031] The wrapping paper 2 also comprises, between the first and second paper layers 4, 6, a moisture-proof layer 8 consisting essentially of paraffin wax. Here, the word "substantially" means that materials other than paraffin wax are allowed to be mixed into the moisture-proof layer 8 to the extent that the direct decomposability of the moisture-proof layer 8 is not adversely affected.

[0032] However, in order ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com