Exhaust gas subsequent processing method and method therefor

A technology of metering device and conveying device, which is applied in exhaust treatment, exhaust device, muffler device, etc., can solve the problem of not setting heat exchange, save space, ensure anti-freezing protection, and save energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

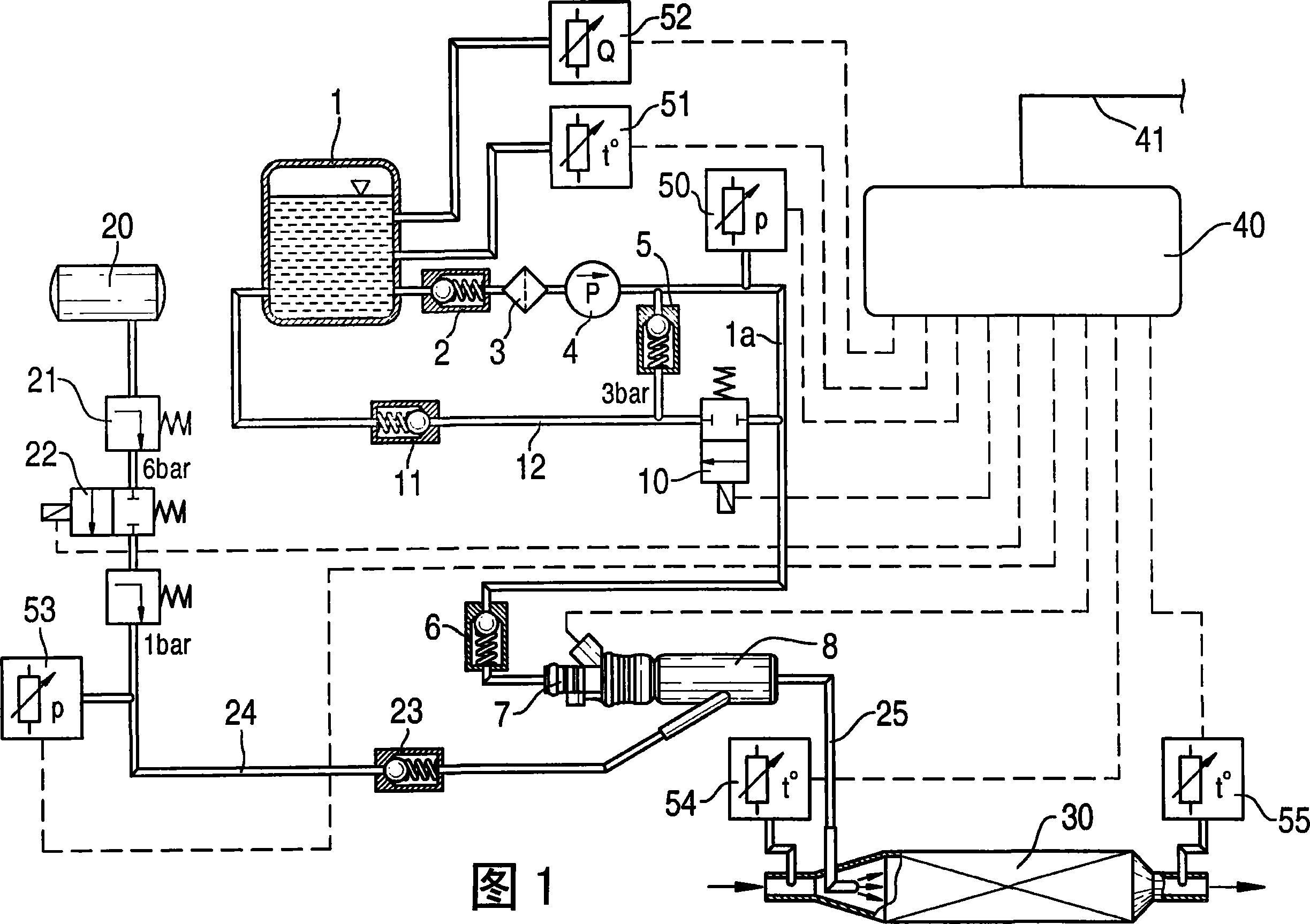

[0018] FIG. 1 shows a device for aftertreatment of exhaust gases. Reference numeral 1 denotes a urea container from which aqueous urea solution is drawn by a delivery pump 4 via a line 1a, for example a hose line, with a non-return valve 2 and a filter 3 formed as a filter sieve and is drawn via Another check valve 6 feeds a metering valve 7 . The metering valve 7 meters the required aqueous urea solution into a mixing chamber 8 . A possible overflow of aqueous urea solution can be conveyed back to the urea container 1 via a return line 12 via a pressure regulator 5 and a further non-return valve 11 . Any necessary degassing of line 1 a takes place via a degassing circuit with a degassing valve 10 . Furthermore, reference numeral 20 denotes a compressed air container, from which compressed air can be introduced into the mixing chamber via a pressure limiter 21 , a 2 / 2-way valve 22 and a non-return valve 23 . The introduction of the reducing agent-air mixture from the mixing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com