Method for processing fish meat extrusion puffing food

A technology of puffed food and processing method, which is applied in the field of muscle tissue processing, to achieve the effects of simple operation, improved nutritional value, and beneficial to industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1: the preparation of quality improver

[0029] Take 10kg of 45% white wine, add 15g of antioxidant BHA, add part of water, then add 100g of sodium polyphosphate, 45g of glucono-δ-lactone, glucose oxidase (derived from Aspergillus niger, activity ≥ 10000u / ml (pH7 .0), liquid, Shanghai Baofeng Biochemical Co., Ltd.) 500u, trehalose 2g, ascorbic acid 10g, add water quantitatively to 30000g, mix evenly to obtain a quality improver.

Embodiment 2

[0030] Embodiment 2: the preparation of quality improver

[0031] Get 8 kg of 55-degree liquor, add antioxidant TBHQ 8 g, add water, then add sodium hexametaphosphate 60 g, glucono-δ-lactone 45 g, glucose oxidase (derived from Aspergillus niger, activity ≥ 10000u / ml (pH7. 0), liquid, Shanghai Baofeng Biochemical Co., Ltd.) 30000u, trehalose 0.5g, D-iso-Vc sodium 50g, add water quantitatively to 30000g, mix well to obtain a quality improver.

Embodiment 3

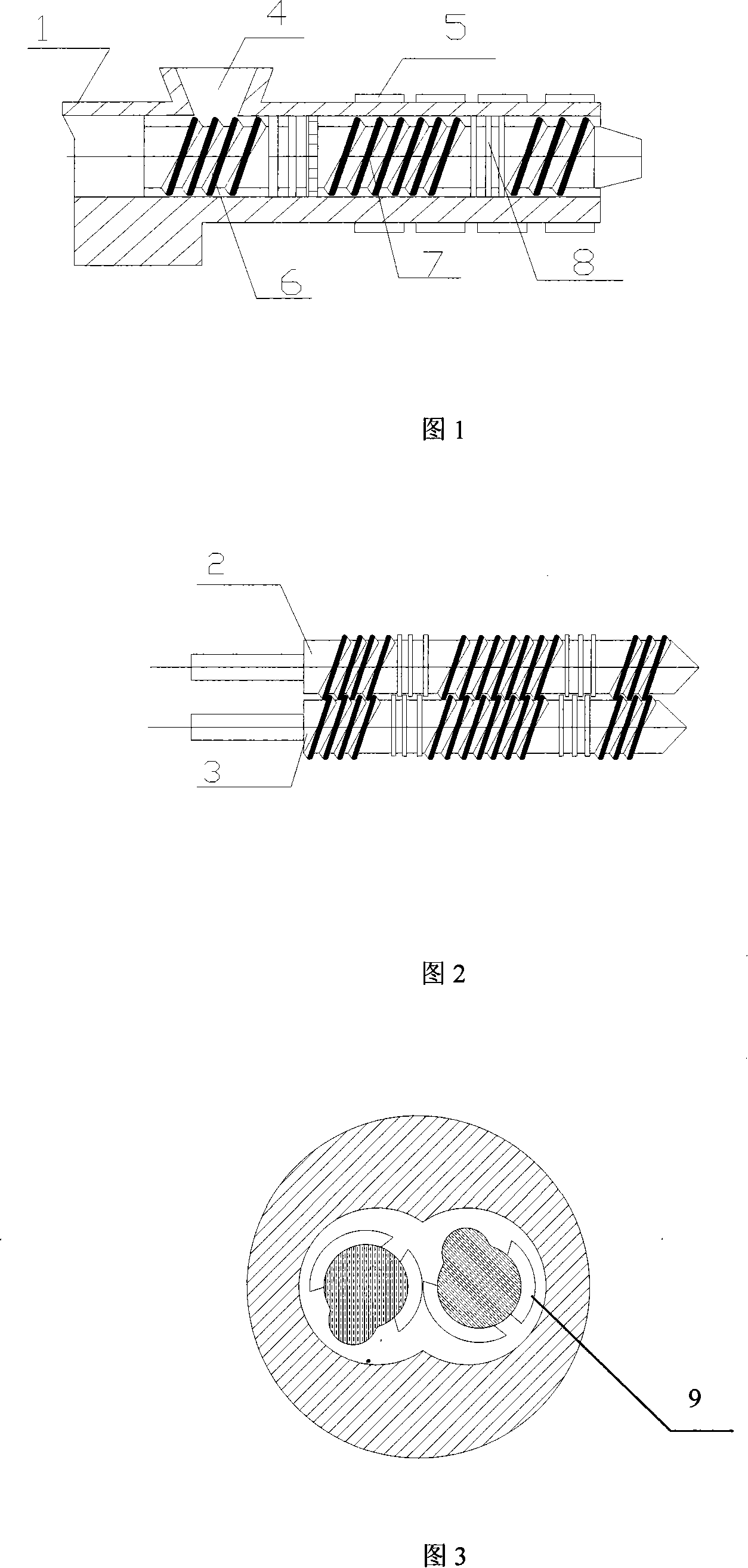

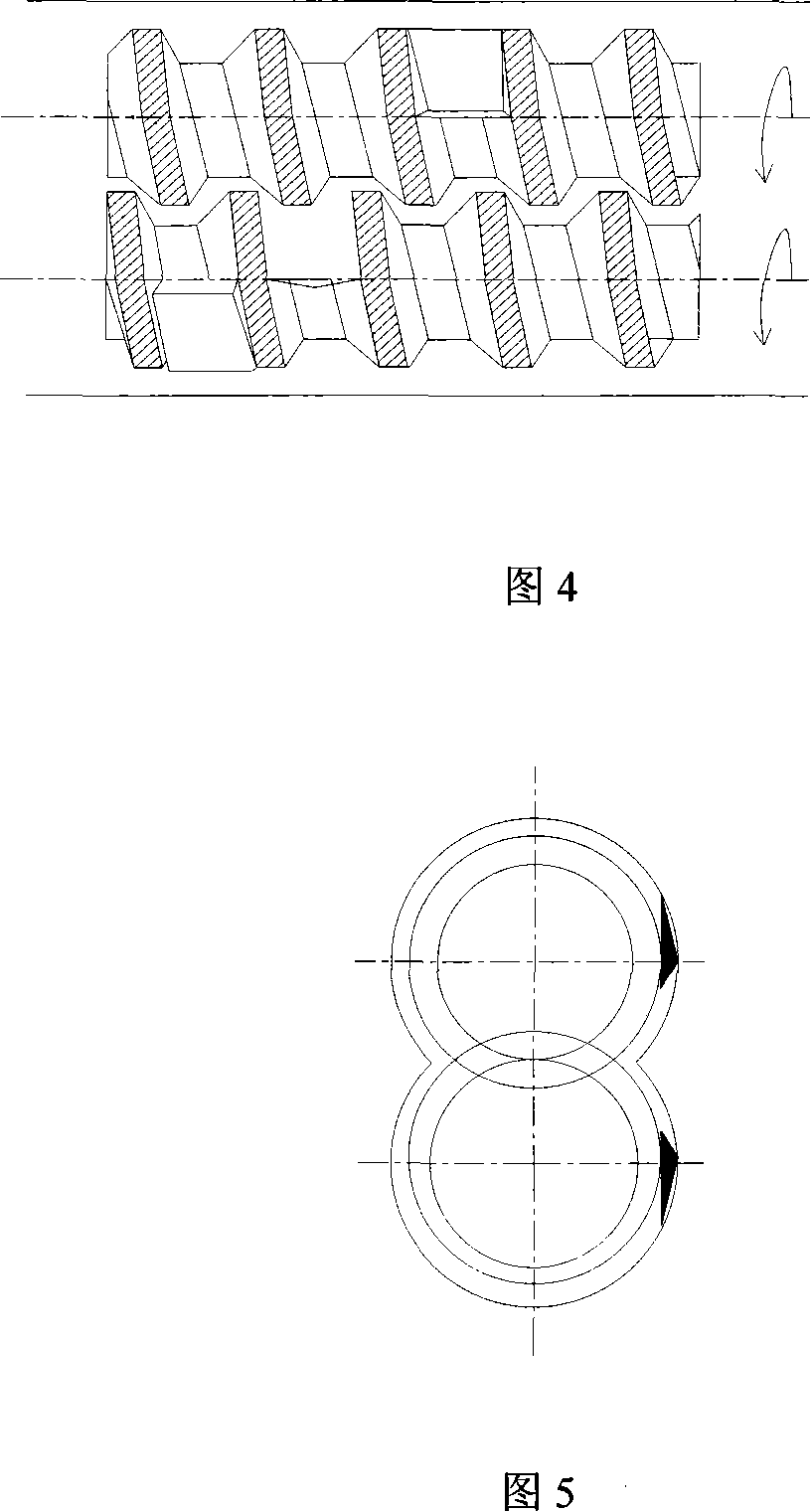

[0033] The structural diagram of the twin-screw extrusion puffing machine is shown in Figures 1 to 5. The twin-screw extrusion puffing machine includes a barrel 1, a first screw 2 and a second screw 3 connected to the power unit. There is a feed port 4, the first screw 2 and the second screw 3 are located in the barrel 1, the first screw 2 is engaged with the second screw 3, the barrel 1 is provided with a jacket, the The first screw 2 and the second screw 3 sequentially include a feeding screw section 6, a plasticizing screw section 7, and an extrusion screw section 8 along the processing direction, and the described feeding screw section 6, plasticizing screw section 7, extrusion Corresponding heating devices 5 are respectively installed in the jackets on the outside of the outlet screw section 8, the feed inlet 4 is connected to the feeding screw section 6, the thread on the feeding screw section 7 is provided with sawtooth, and the The screw end of the extruding screw segm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com