Electromotor structure

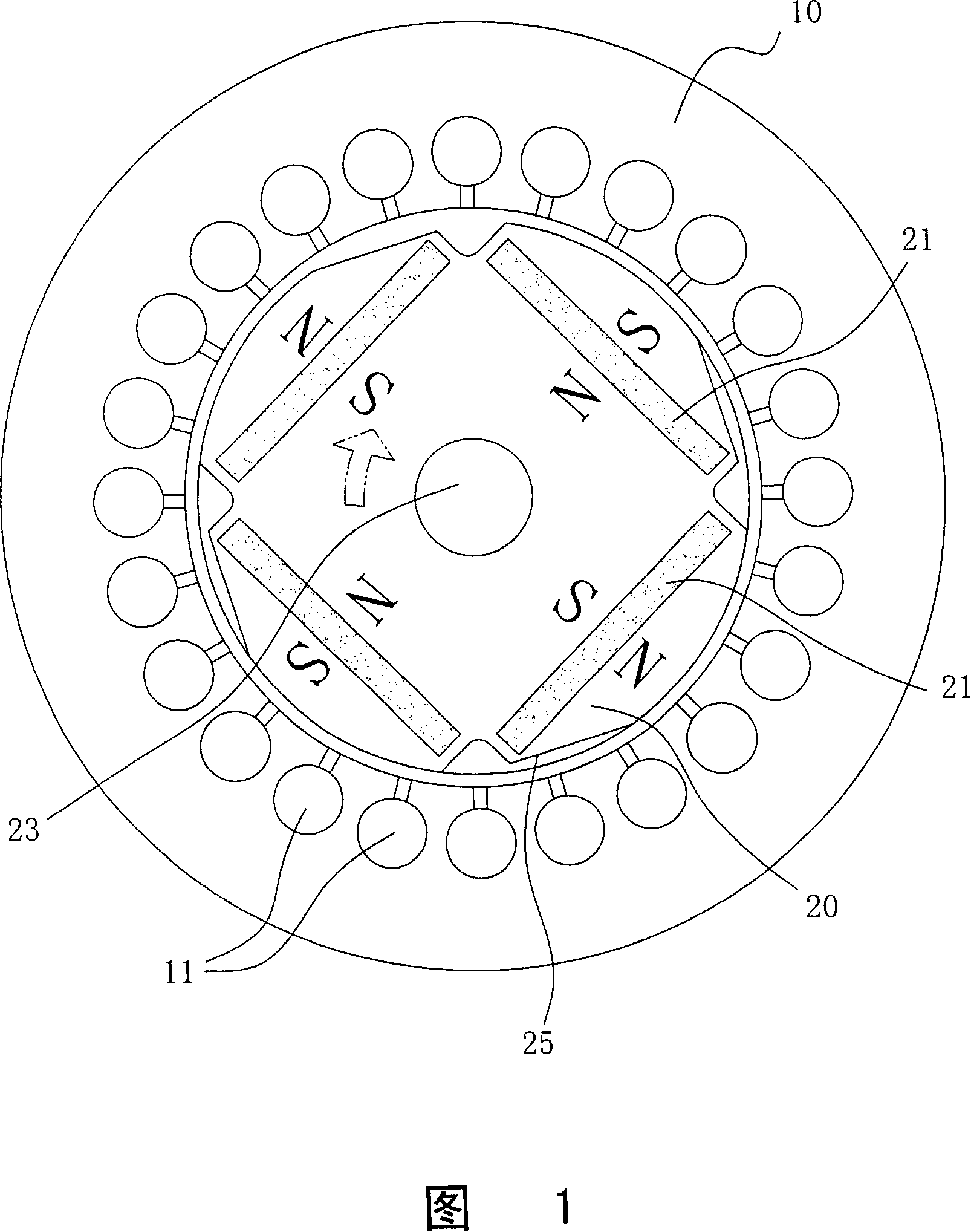

A motor and armature technology, applied in the shape/style/structure of the magnetic circuit, the rotating parts of the magnetic circuit, the static parts of the magnetic circuit, etc., can solve the problem that the magnetic repulsion is weak, cannot be improved, and increases the power consumption of the secondary repulsion. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The foregoing and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of two preferred embodiments with reference to the accompanying drawings.

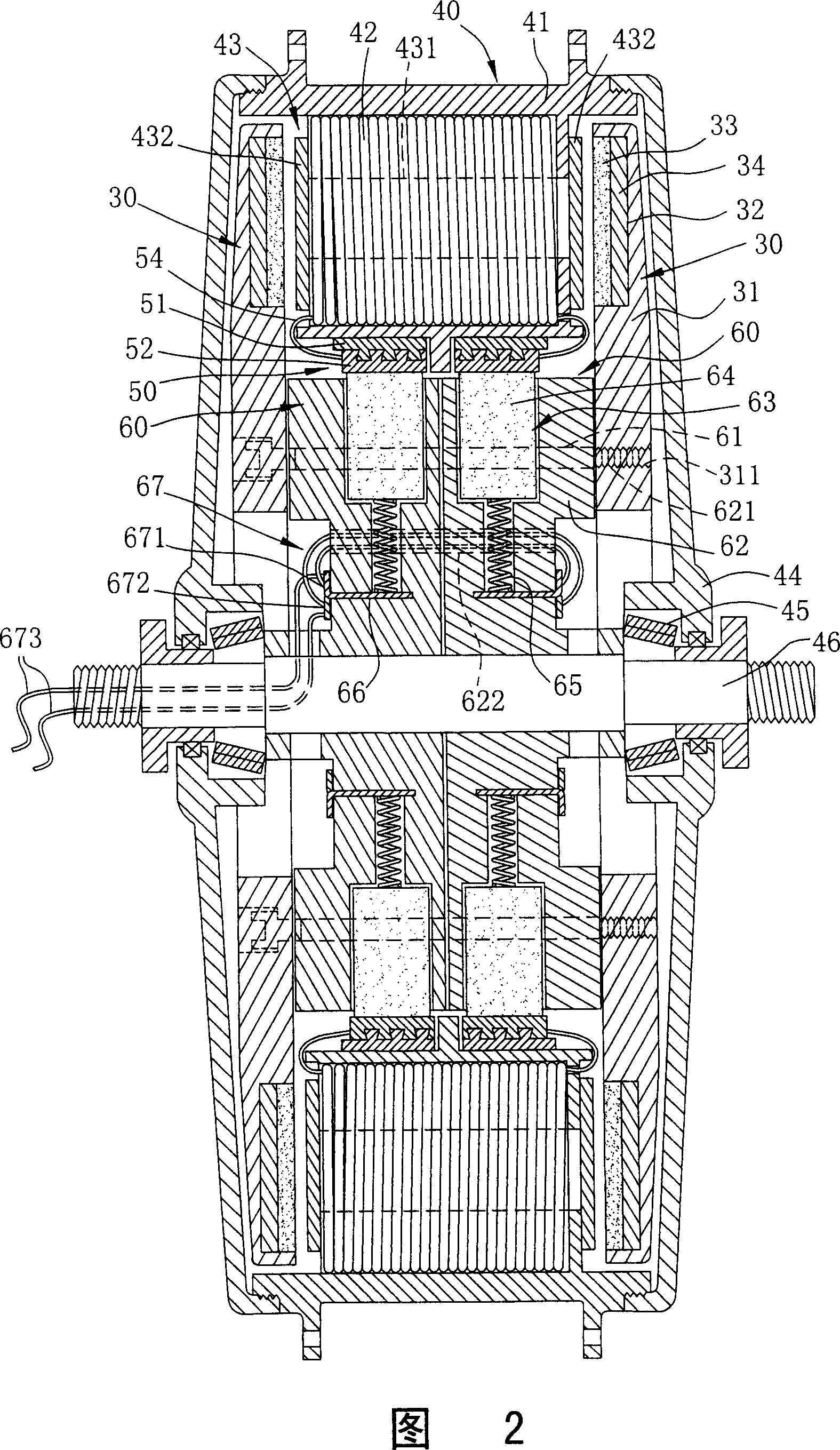

[0030] Fig. 2 is a schematic cross-sectional view of the first preferred embodiment of the motor structure of the present invention, which is mainly the structure of a brushed motor. As shown in the figure, the motor of the present invention mainly includes an inner armature 30 , an outer armature 40 , two commutators 50 , and two carbon brush sets 60 .

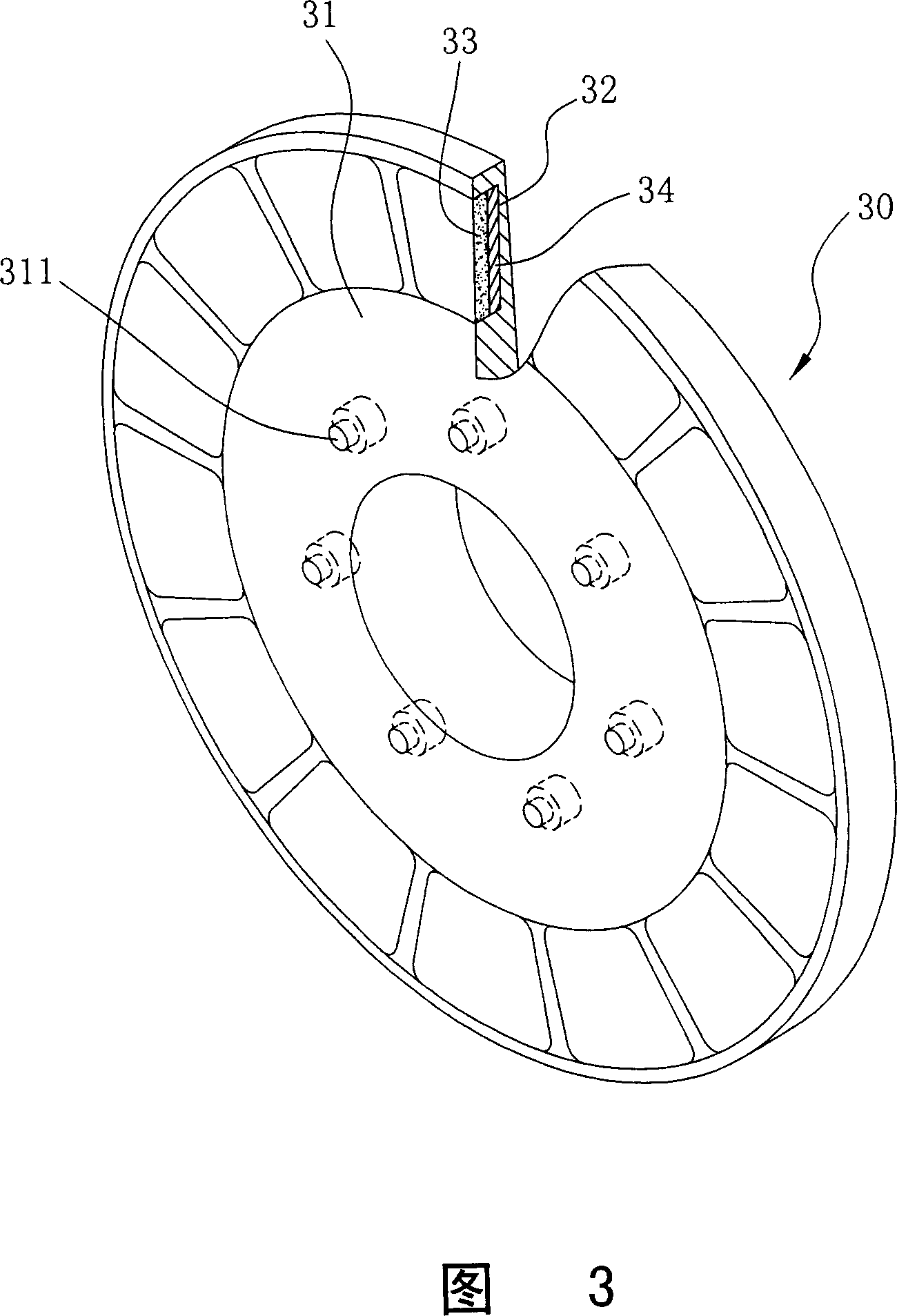

[0031] Please refer to FIG. 3 to FIG. 5 together. The inner armature 30 is provided with at least two layers of substrates 31, which are arranged opposite to each other. Hole 32 is established. Each of these installation holes 32 is embedded with a permanent magnet 33, so that two adjacent permanent magnets 33 have opposite magnetic poles; 33, the magnetic field lines of these permanent magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com