Harvester for potatoes

A technology for harvesters and potatoes, which is applied to digging harvesters, harvesters, excavators, etc., can solve problems such as large fluctuations, choked soil, and poor operation adaptability, and achieve stable excavation depth, smooth soil flow, and simple manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

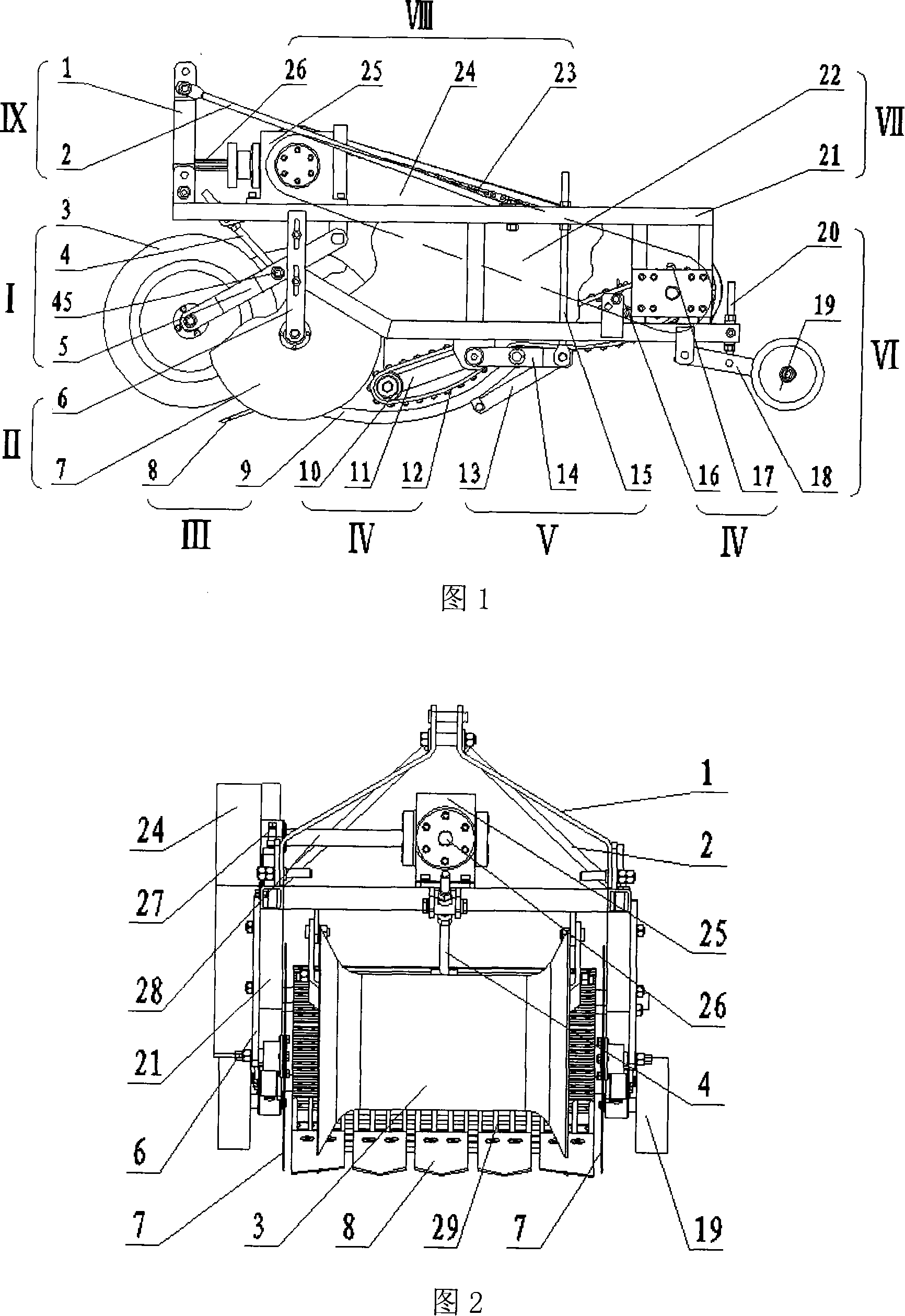

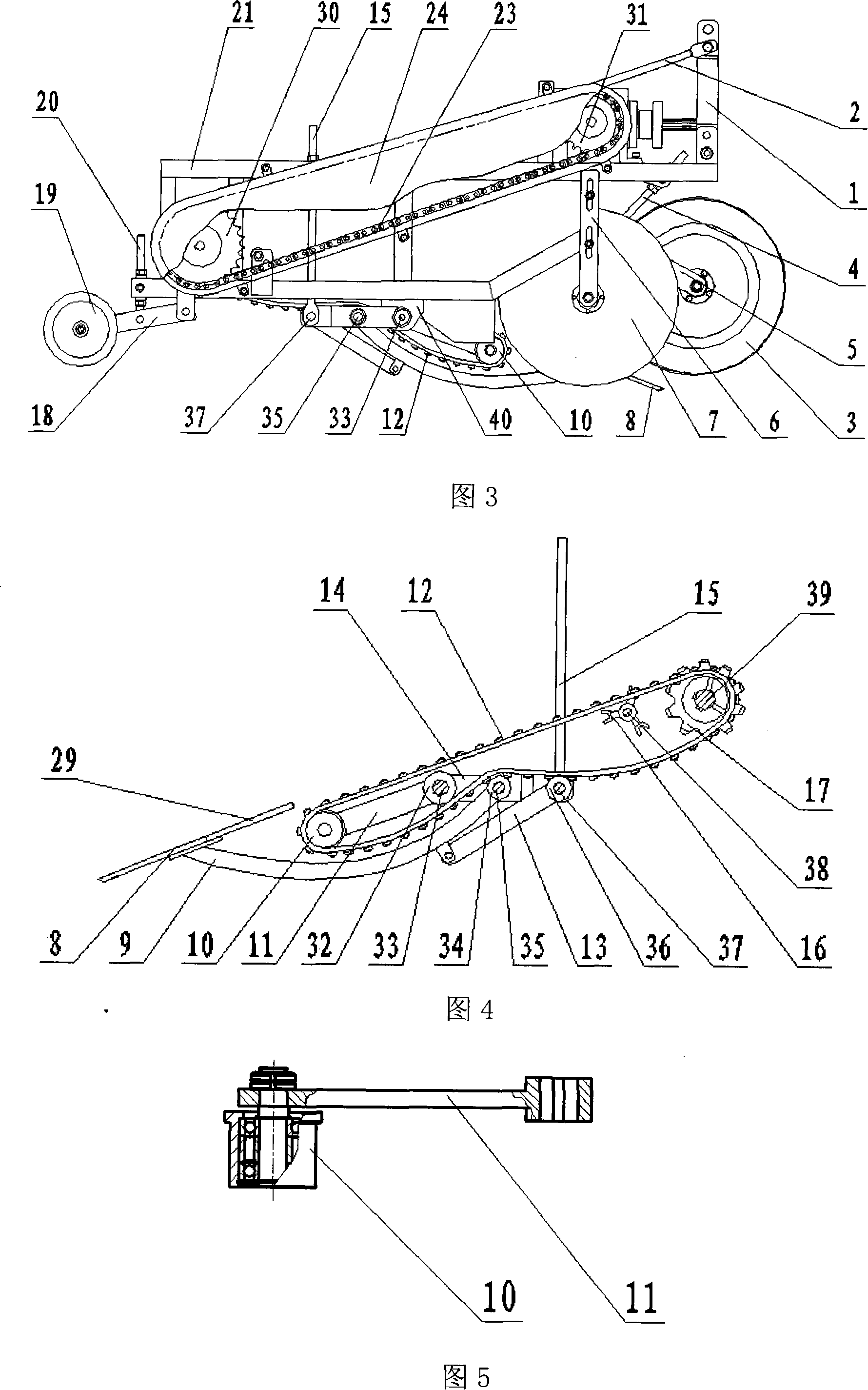

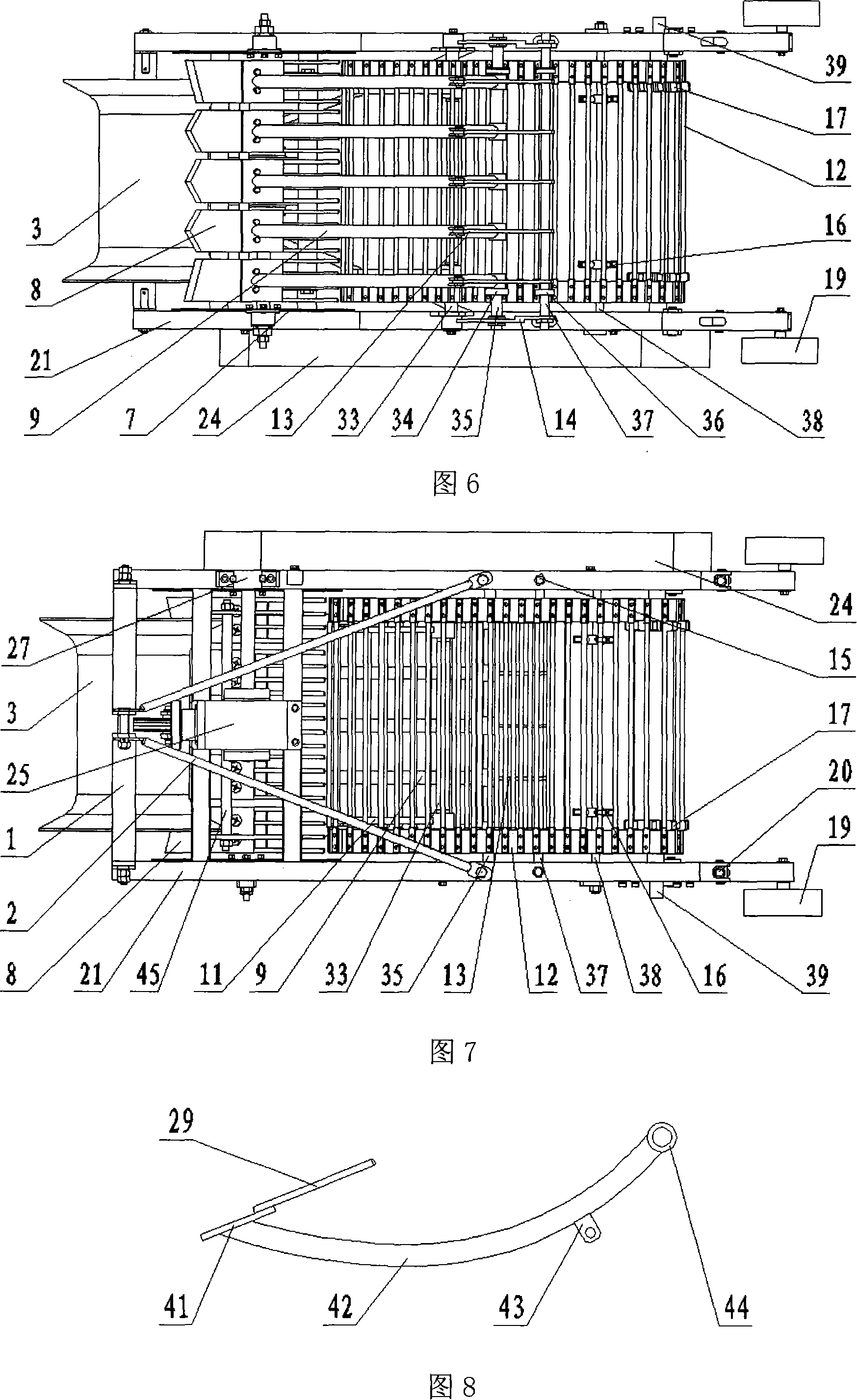

[0026] The invention provides a safe and reliable potato harvester adaptable to various ridge heights and digging depths, convenient to adjust, stable in work, small in resistance, free from congestion. The present invention will be specifically described below in conjunction with the accompanying drawings.

[0027] The potato harvester shown in Fig. 1 includes I-profiling suppression device; II-soil-cutting and leak-proof garden disc device; III-digging shovel assembly; IV-rod type shaking lifting device; V-shovel chain synchronous adjustment mechanism; VI-supporting running gear; VII-frame; VIII-transmission system; IX-suspension frame. Among them, the profiling suppressing device I is installed in front of the excavating shovel assembly III, the soil cutting and leak-proof disc device II is installed on both sides of the excavating shovel assembly III, and the rod-type vibrating lifting device IV is behind the excavating shovel assembly III. The shovel chain synchronous ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com