Minuteness milling tool spark-erosion machining method and electrode special for the same

A technology of micro-milling and processing methods, applied in electric processing equipment, electrode manufacturing, metal processing equipment, etc., can solve the problems of micro-milling cutter manufacturing problems, etc., and achieves the advantages of eliminating ionization, overcoming easy wire breakage, accurate size and easy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

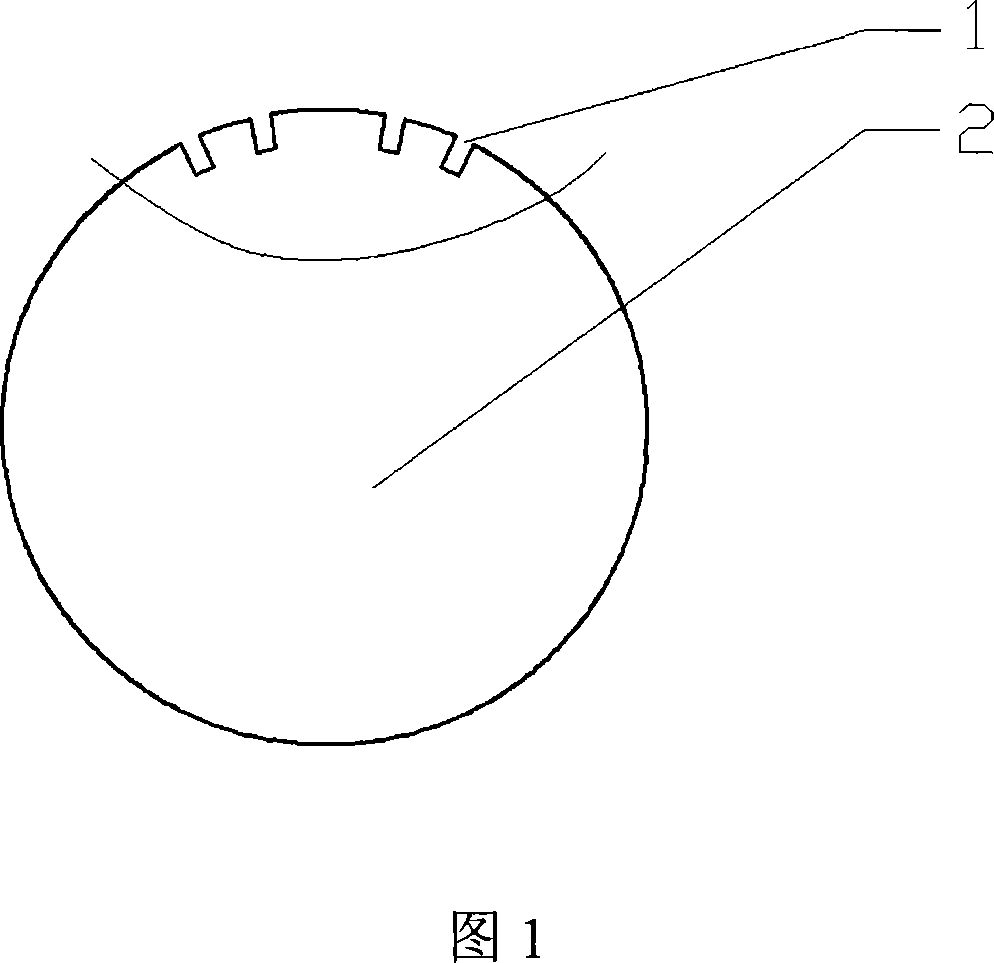

[0013] Fig. 1 is a schematic diagram of a micro-grooved disc electrode of the present invention.

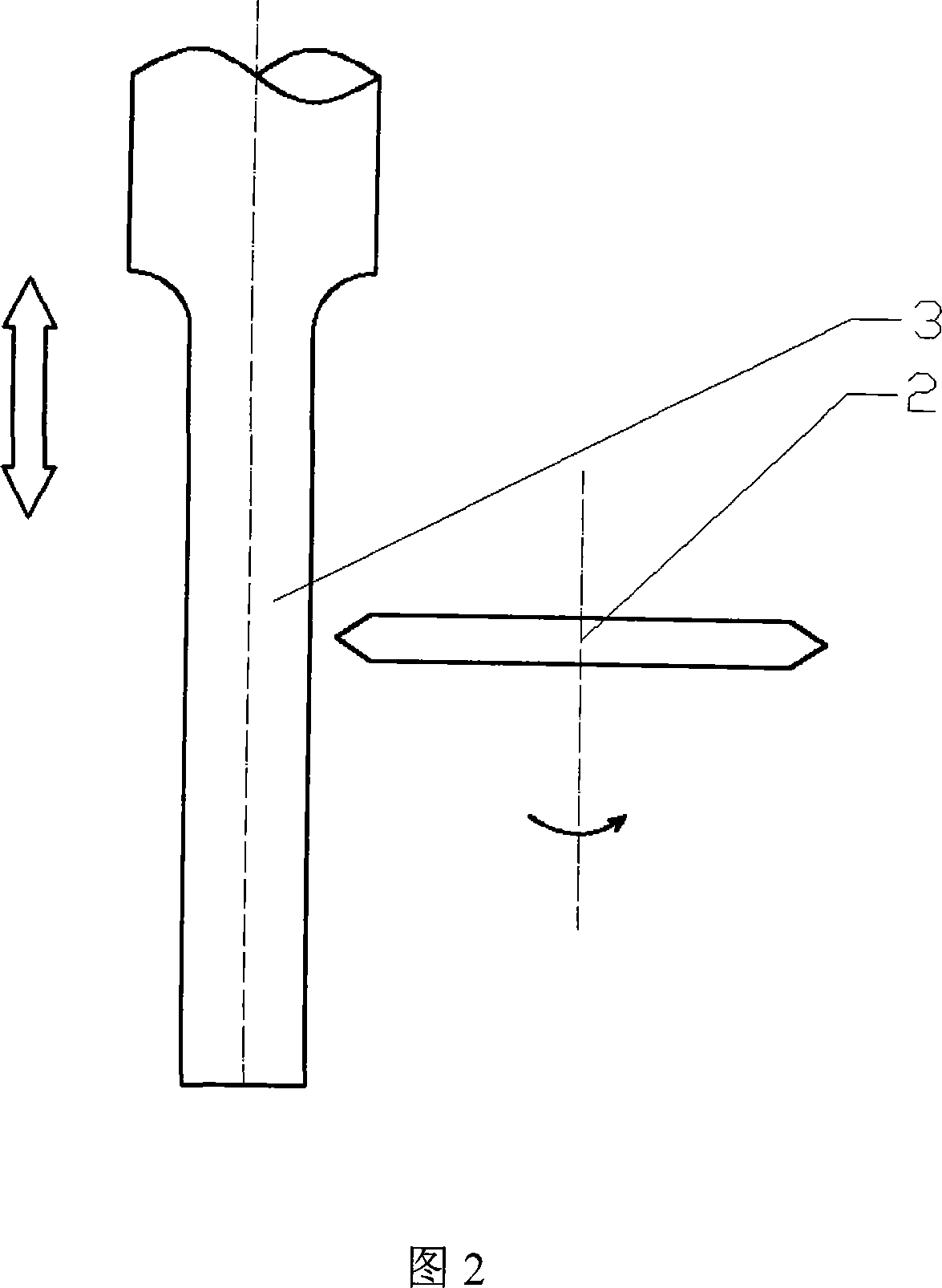

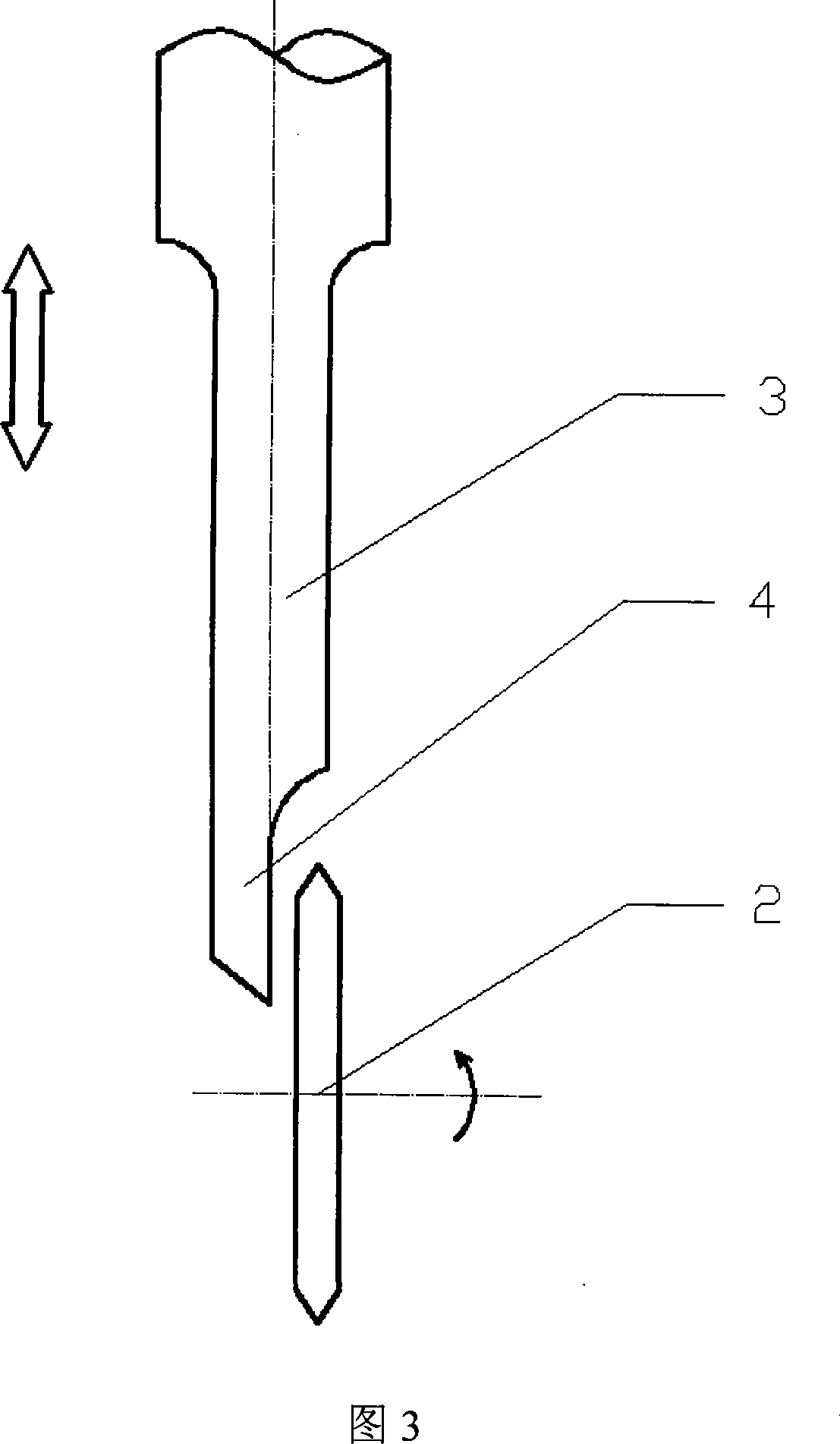

[0014] Fig. 2 and Fig. 3 are two schematic diagrams of a preferred embodiment of the electric discharge machining method of the micro milling cutter of the present invention.

[0015] (1) Make a micro-slotted disc electrode, and clamp the prepared micro-slotted disc electrode on the high-speed spindle.

[0016] (2) Place an electric discharge machining device equipped with a micro-slotted disk electrode on the side of the micro-milling cutter, and process the cutter body part of the micro-milling cutter.

[0017] (3) Place an electric discharge machining device equipped with a micro-slotted disk electrode under the cutter head of the micro-milling cutter to process the cutting edge of the micro-milling cutter.

[0018] (4), the machining diameter of the micro milling cutter is 50 microns, and the machining length of the cutter body is 2000 microns. In steps (2) and (3), the work...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com