Explosion welding repair method of infusible uncommon metal composite board

A technology of rare metal plates and rare metals, which is applied in welding equipment, metal processing, metal processing equipment, etc., and can solve the problems of high price of clad metals, scrapping of composite plates or equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

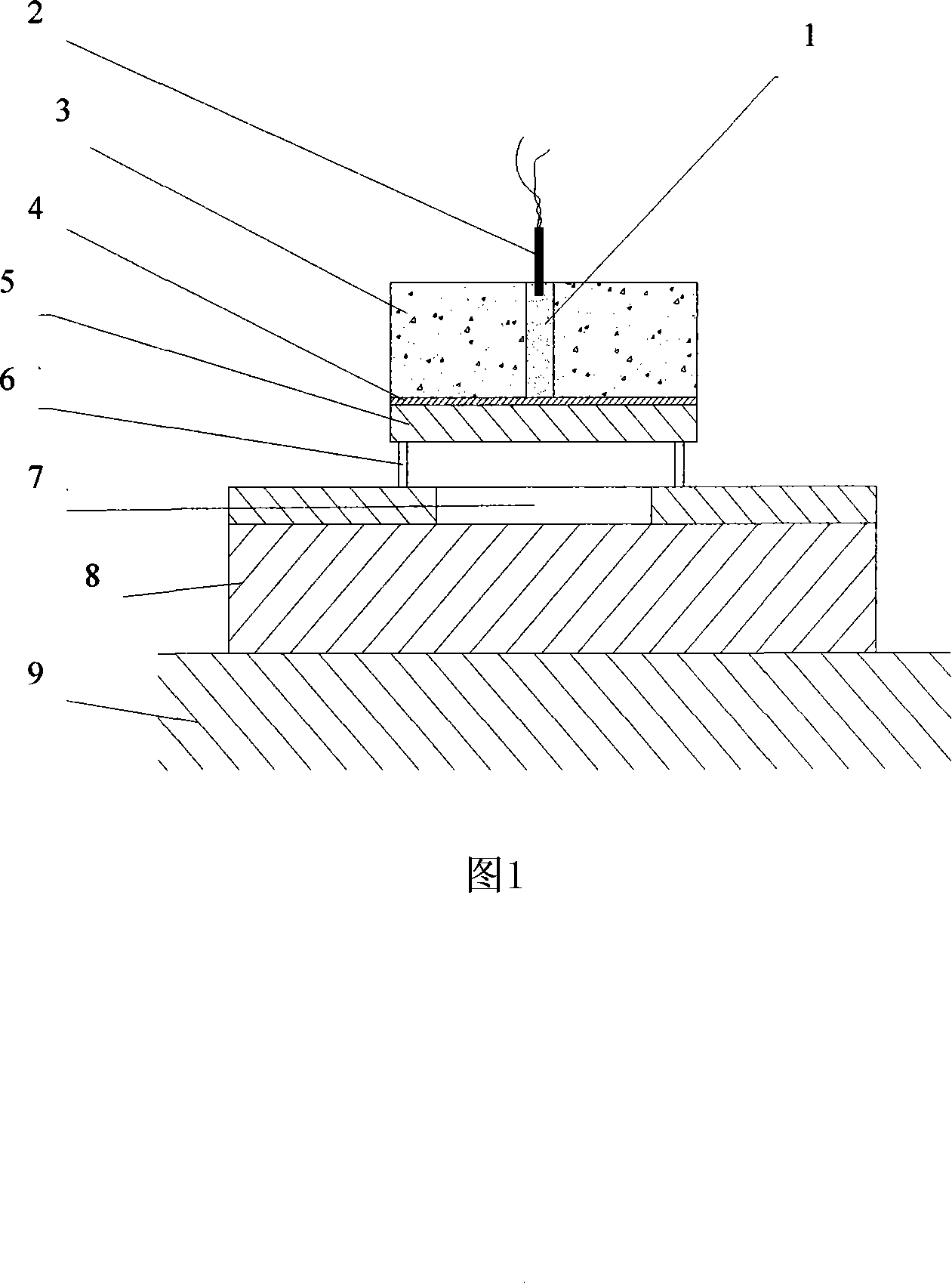

[0011] The explosive welding repair method of the refractory rare metal composite plate is as follows: when installing on site, the rare metal composite steel plate is used as the lower layer of the substrate, and the rare metal plate is placed on the defective part. First, the support gap between the two plates is increased by 8mm, and the edge Support gaps, parallel placement, doubler boards are 20mm larger than the defect area, to meet the needs of uniform force distribution on the entire board, to ensure that the final repair area is welded at one time, and in order to prevent explosives from burning the doubler board surface during the explosive compounding process, the protective layer must be Thickened to 0.5-1mm. The thickness of the rare metal plate is 1.5-16mm, the thickness of the base plate is 8-100mm steel plate, the main explosive is 2# rock explosive, and the detonation velocity is 2200-3500mm / s. After the surface of the rare metal plate is protected, 2# rock ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com