Graphite boat for improving mercury cadmium telluride rheotaxy membrane surface shape

A technology of liquid phase epitaxy and surface morphology, which is applied in the field of graphite boats, can solve problems such as surface ripples and epitaxial film surface ripples, and achieve the effects of reducing ripples, eliminating unevenness, and slowing down mother liquor convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

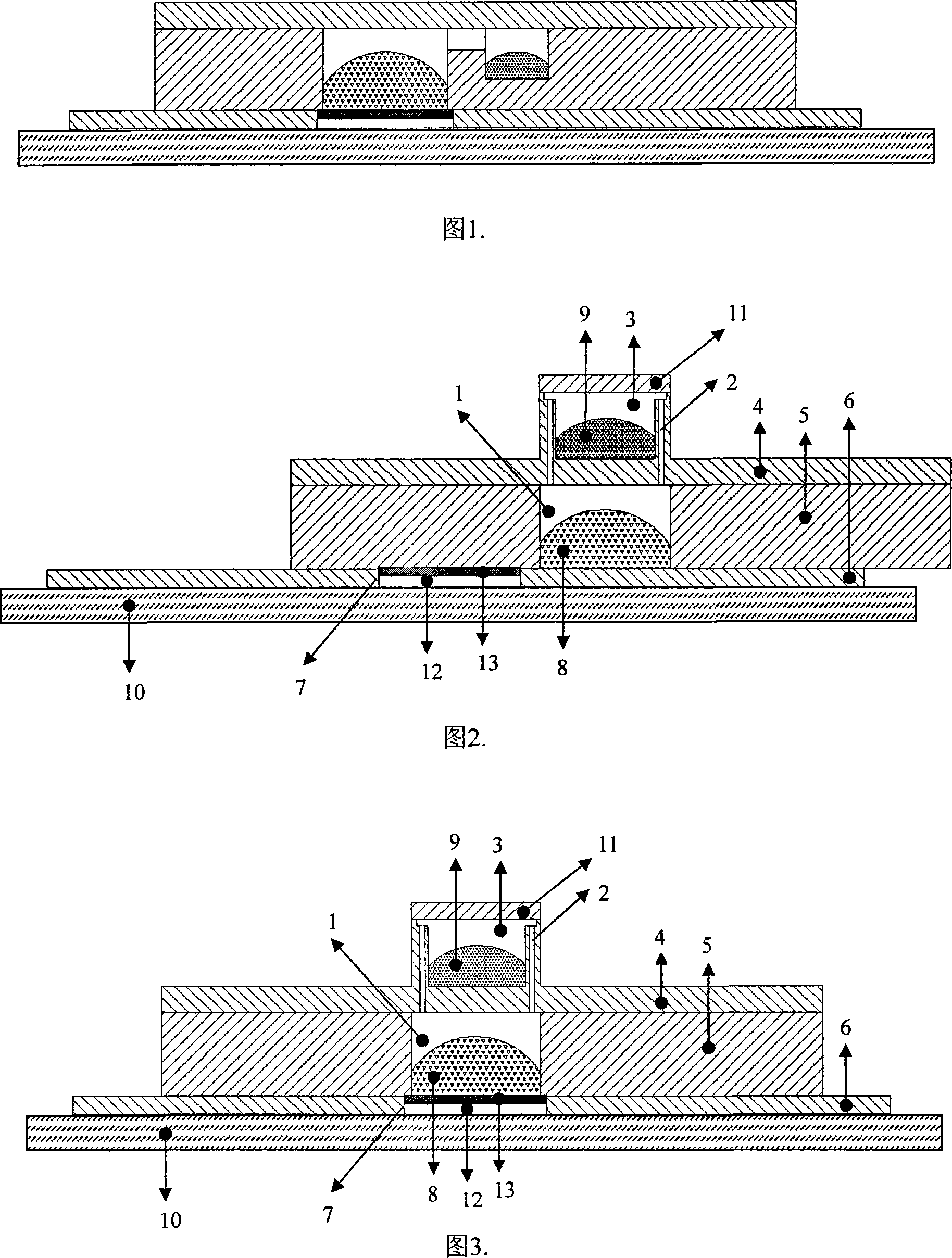

[0012] The specific embodiment of the present invention is described in further detail below in conjunction with accompanying drawing:

[0013] Graphite boat of the present invention comprises: base plate 6, slide block 5, cover plate 4 and base 10, base plate 6 is fixed on the base 10, slide block 5 places above the base plate, and slide block can move left and right relative to base plate. There is a substrate channel with the same size as the epitaxial substrate on the base plate, and the substrate channel uses the base as a support to form a substrate groove 7. The substrate groove is equipped with a quartz gasket 12 for adjusting the height of the substrate and the notch. The quartz gasket Place the substrate 13 on it. The slide block 5 is provided with a mother liquid channel for placing the mother liquid 8, and the mother liquid channel will be located in the middle of the slide block, so as to make the mother liquid 8 evenly heated. The mother liquid channel uses the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com