Molding composition and method, and molded article

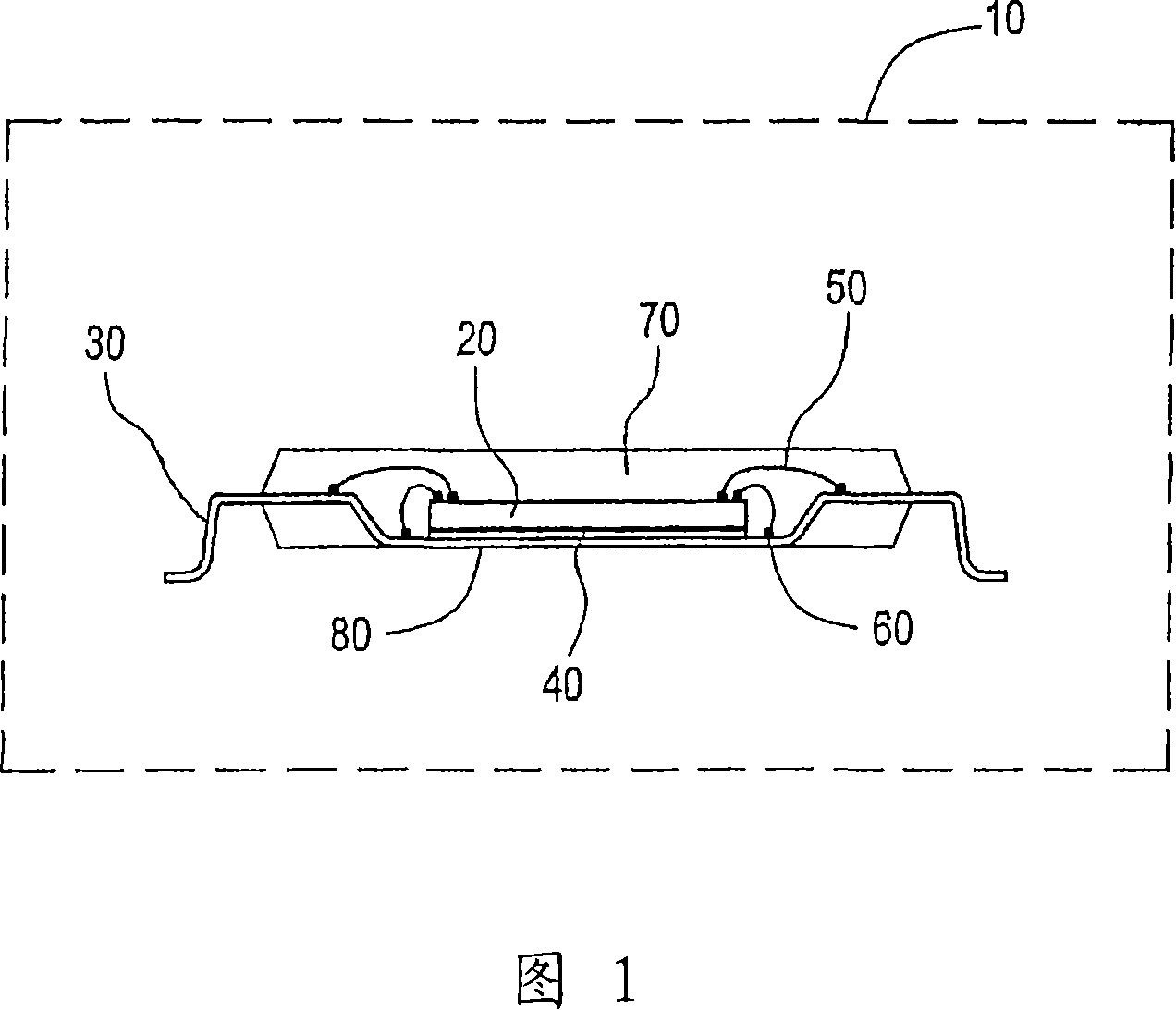

一种组合物、环氧树脂的技术,应用在运输和包装、电固体器件、半导体器件等方向,能够解决降低流动性、增加缺陷、损害可模塑性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

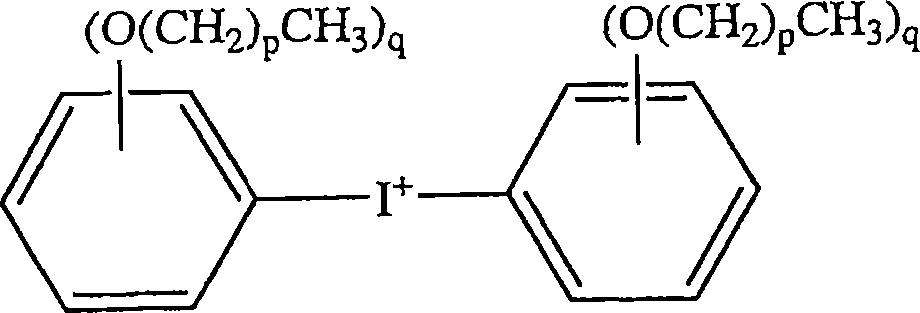

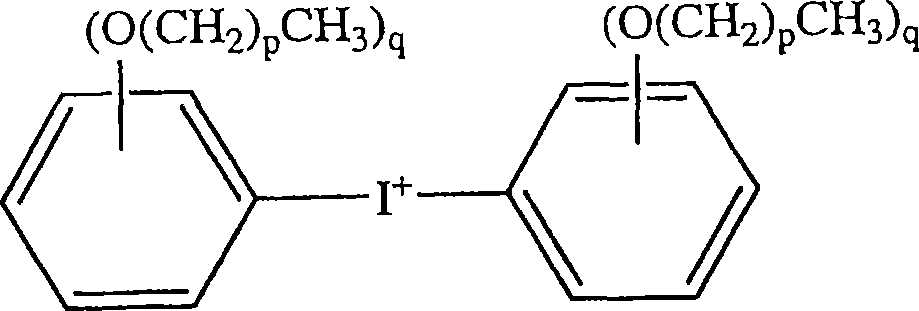

[0150] The compositions specified in Table 1 were mixed as described above. Examples 1-3 are comparative examples. The amounts of all components in Table 1 are expressed in parts by weight. Embodiment 4 is an embodiment of the present invention. "Denka FB570 Silica" is a fused silica obtained from Denka, which has a median particle size of 17.7 microns and a surface area of 3.1 meters 2 / gram. "Denka SFP Silica" is a fused silica obtained from Denka having a median particle size of 0.7 microns and a surface area of 6.2 meters 2 / gram. "Yuka RSS1407LCepoxy" available from Yuka Shell is 3,3',5,5'-tetramethyl-4,4'-diglycidyloxybiphenyl. "Sumitomo ECN-195XL-25" from Sumitomo Chemical is an epoxidized o-cresol novolak resin. "OPPI" is (4-octyloxyphenyl)(phenyl)iodonium hexafluoroantimonate available from GE Advanced Materials-Silicones as UV9392c. "OPPI O3SC4F9" is (4-octyloxyphenyl)(phenyl)iodonium nonafluoro-n-butanesulfonate. It was prepared as follows: 50 g of (4-oc...

Embodiment 5 and 6

[0157] A curable composition was prepared by mixing the materials listed in Table 3 as described above. The amounts of all components in Table 3 are expressed in parts by weight. Example 5 is a comparative example, while Example 6 is an application example of the present invention.

[0158] table 3

[0159] Element

Example 5

Example 6

Denka FB570 Silica

1575

1429.02

Denka SFP Silica

175

158.78

Nippon Kayaku NC-3000 epoxy resin

235.3

212.44

OPPI

2.35

2.12

OPPI O 3 SC 4 f 9

0

1.06

Benpinacol

2.35

2.12

6.0

5.44

4.0

3.63

[0160] The measured characteristic values are shown in Table 4 below. These data again demonstrate that increased helical flow is achieved with mixed catalysts.

[0161] Table 4

[0162] test

Embodiment 7 and 8

[0164] The materials listed in Table 5 were mixed as described above to obtain curable compositions. The amounts of all components in Table 5 are expressed in parts by weight. Embodiment 7 is a comparative example when the amount of filler added is 90%, and Example 8 is an application example of the present invention when the amount of filler added is the same.

[0165] table 5

[0166] Element

Example 7

Example 8

Denka FB570 Silica

1620

1620

Denka SFP Silica

180

180

37.33

37.07

Sumitomo ECN-195XL-25

149.31

148.3

OPPI

2.24

1.85

OPPI O 3 SC 4 f 9

0

0.93

Benpinacol

1.12

1.85

6.0

6.0

4.0

4.0

[0167] The measured characteristic values are shown in Table 6 below. Comparing the helical flow values for Example 5 with a single iodon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com