Lubricating grease composition

A technology of grease composition and mixture, applied in the directions of lubricating composition, thickener, petroleum industry, etc., can solve problems such as improvement of friction and corrosion performance not involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

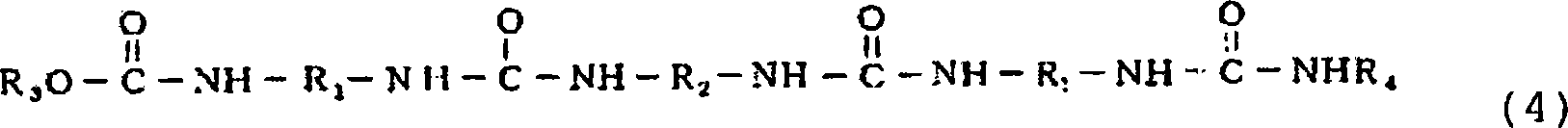

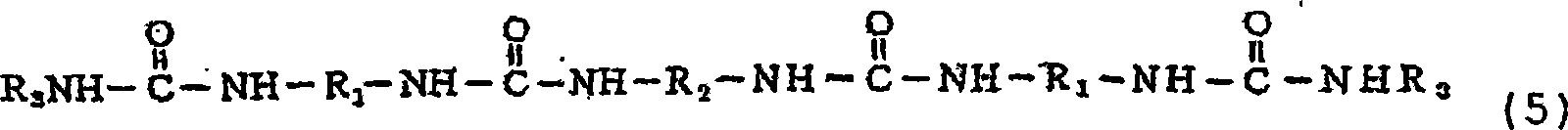

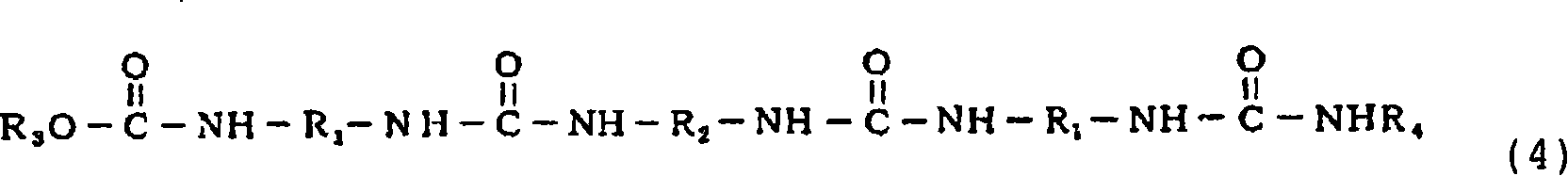

Method used

Image

Examples

Embodiment 1-5

[0114] Grease compositions were obtained by mixing the thickener, base oil and additives shown in Table 1 in the proportions shown in Table 1 and heating.

[0115] Table 1 shows the results of measuring the penetration, dropping point (° C.) and anti-friction (room temperature) of the obtained grease composition.

[0116] Table 1

[0117] Example 1

Example 2

Example 3

Example 4

Example 5

thickener

Diurea compounds:

Aliphatic A

10

10

10

10

10

89

89

89

89

89

Additives

Mg-St

1

Ca-St

1

Ca-12(OH)St

1

Zn-St

1

Al-St

1

result

Penetration (dmm)

285

282

284

283

281

Dropping point, ℃

>250

>250

>250

>250

>25...

Embodiment 6-13

[0133] Similar experiments were performed by varying the base oil. The results are shown in Table 4.

[0134] Table 4

[0135] Example 6

[0136] According to these results, when the diurea compound and zinc stearate or aluminum stearate were blended into the base oil, both had a great anti-friction and wear inhibitory effect, and the effect of the type of base oil on the anti-friction and wear inhibitory effect was observed Basically no effect.

[0137] Examples of Embodiments 14-17

[0138] Similar experiments were performed by varying the amount of thickener added. The results are shown in Table 5.

[0139] table 5

[0140] Example 14

[0141] According to these results, even when the grease consistency is hard, the anti-friction and wear suppression effect is extremely large.

Embodiment approach 18-29

[0142] Examples of Embodiments 18-29

[0143] A similar experiment was performed by changing the kind of thickener, and its effect was considered. The results are shown in Tables 6 and 7.

[0144] Table 6

[0145] Example

[0146] Table 7

[0147] Example

[0148] Even when the kind of the thickener composed of the urea compound was changed, the result did not change.

PUM

| Property | Measurement | Unit |

|---|---|---|

| drop melting point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com