Method of mechanical pulp making by using cotton pole

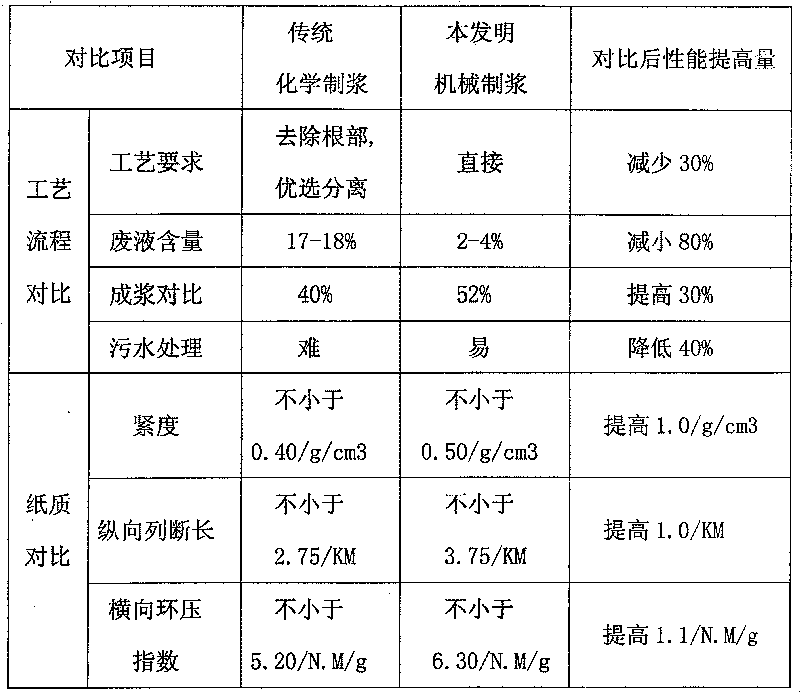

A technology of mechanical pulping and cotton stalks, applied in the field of paper pulping, can solve the problems of low utilization rate of cotton stalks, high chemical composition of waste liquid, low pulping rate of cotton stalks, etc., and achieve easy sewage treatment, waste liquid chemical The effect of low composition and process optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051]The method of this embodiment is implemented according to the aforementioned steps, and the relevant parameters are controlled according to the following values:

[0052] Step A is material preparation, that is, the cotton stalks are chopped into 2cm segments by a mechanical device.

[0053] Step B is dedusting and splitting, which specifically includes

[0054] B1, a section of dust removal and filament separation,

[0055] B2, second-stage dust removal and filament separation.

[0056] Step C is cooking, and the vermicelli-shaped fiber slurry made in step B2 is dropped into a steaming ball, and the vermicelli-shaped fiber slurry is mixed with NaOH accounting for 1.5% of the total mass of the slurry, and the pressure is evenly increased and the temperature is raised. When the pressure reaches 0.7 MPa±0.01MPa, when the temperature reaches 165°C±2°C, the time to keep the pressure and temperature stable is 120 minutes, and it takes 7 hours for the whole process from seal...

Embodiment 2

[0064] The method of this embodiment is implemented according to the aforementioned steps, and relevant parameters are controlled according to the following values:

[0065] Step A is material preparation, that is, the cotton stalks are chopped into small sections of 3 cm by a mechanical device.

[0066] Step B is dedusting and splitting, which specifically includes

[0067] B1, a section of dust removal and filament separation,

[0068] B2, second-stage dust removal and filament separation.

[0069] Step C is cooking, put the slurry made in step B2 into the steaming ball, add 2.0% NaOH accounting for the total mass of the slurry in the slurry, uniformly increase the pressure and temperature, when the pressure reaches 0.8MPa ± 0.01MPa, the temperature reaches At 170°C±2°C, the time to keep the pressure and temperature stable is 90 minutes, and it takes 6 hours for the whole process from sealing the steaming ball to heating and pressurizing to completing the cooking.

[0070...

Embodiment 3

[0077] The method of this embodiment is implemented according to the aforementioned steps, and relevant parameters are controlled according to the following values:

[0078] Step A is material preparation, that is, the cotton stalks are chopped into 4cm segments by a mechanical device.

[0079] Step B is dedusting and splitting, which specifically includes

[0080] B1, a section of dust removal and filament separation,

[0081] B2, second-stage dust removal and filament separation.

[0082] Step C is cooking, put the slurry made in step B2 into a steaming ball, add 1.7% NaOH accounting for the total mass of the slurry in the slurry, and evenly increase the pressure and temperature. When the pressure reaches 0.75MPa ± 0.01MPa, the temperature When it reaches 168°C±2°C, the time to keep the pressure and temperature stable is 100 minutes, and it takes 6.5 hours for the entire process from the sealing of the steaming ball to the completion of heating and pressure.

[0083] Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com