Microlenses of cmos image sensor and method for fabricating the same

A technology of image sensor and microlens, which is applied in the direction of photographic plate-making process, instrument, electric solid device, etc. on the pattern surface, can solve the problems of limiting the reproducibility of microlens, standardization of focal length of microlens, standardization of difficult reflow treatment, etc., and achieves reproducibility performance optimization, crosstalk minimization, and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

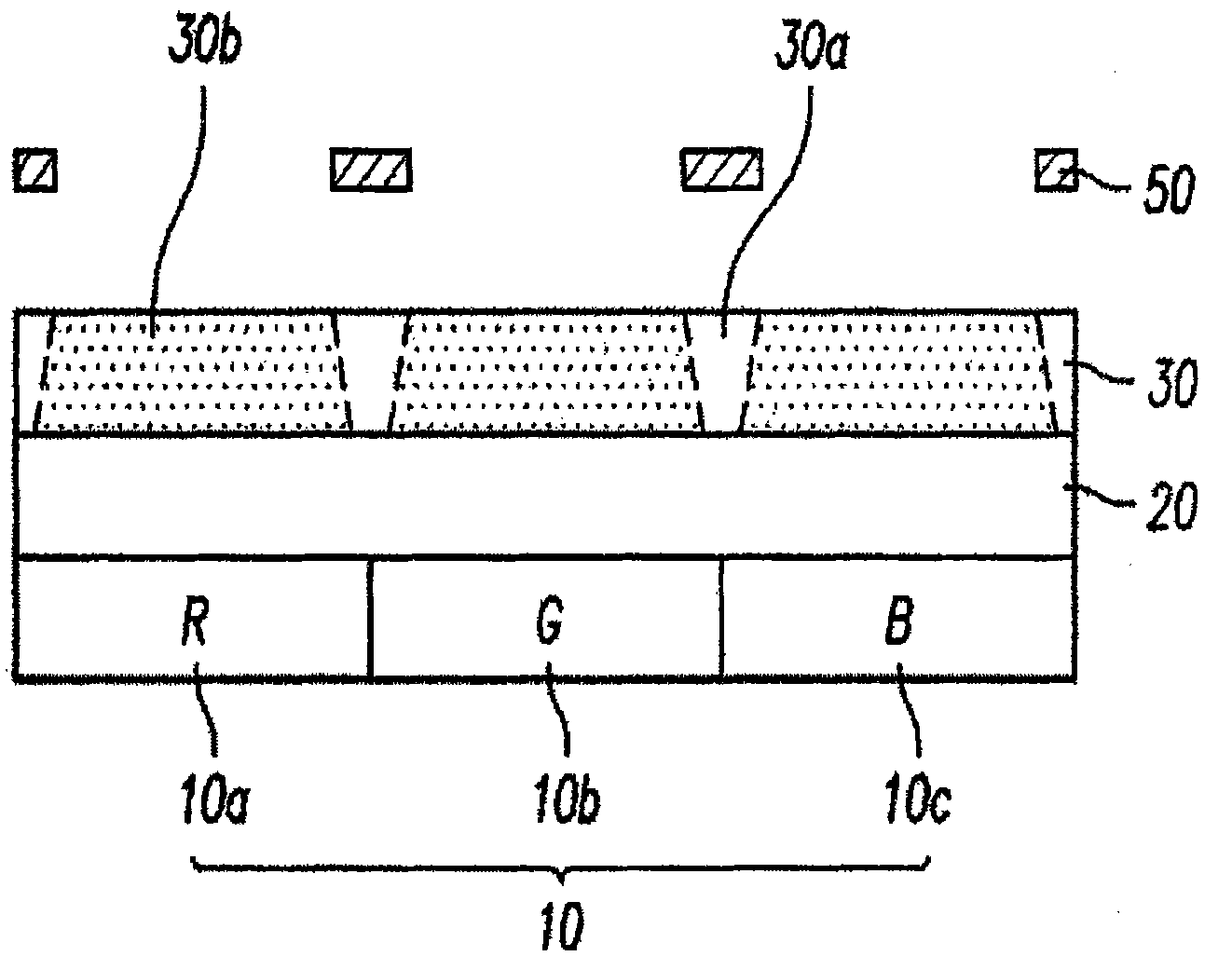

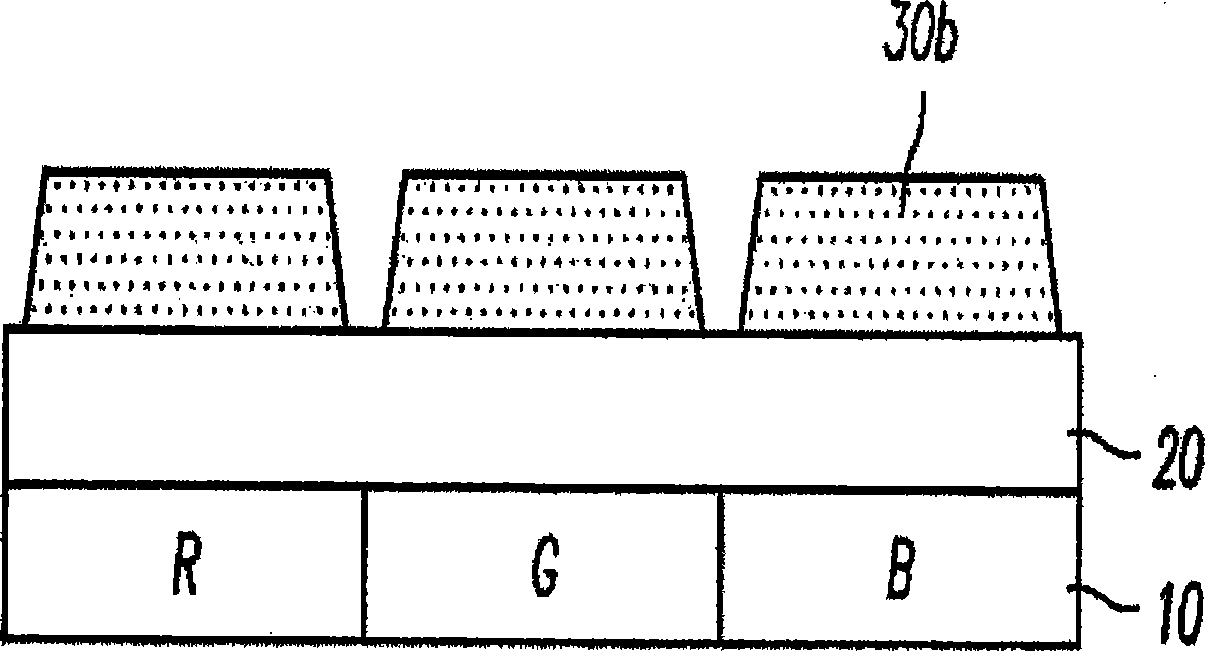

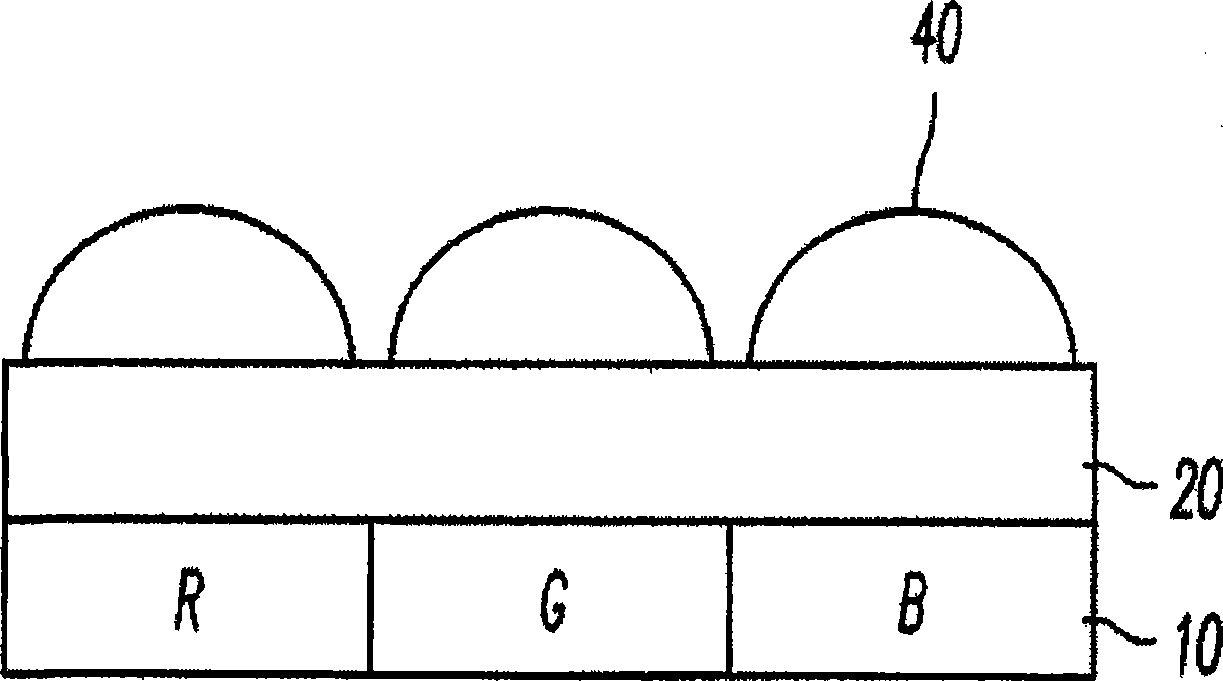

[0017] Such as Figure 2A As shown, color filter array 100 and / or planarization layer 200 are formed on and / or over a semiconductor substrate, according to embodiments.

[0018] Silicon oxide (SiO 2 ) layer 400 is formed on and / or over planarization layer 200 and / or color filter array 100 .

[0019] A plurality of metal wiring layers for electrically connecting circuit elements are formed on and / or over the semiconductor substrate. Circuit elements (eg, a photodiode and / or MOS transistors) are formed on and / or over the semiconductor substrate. Multiple interlayer dielectric layers may be formed to electrically isolate circuit elements and / or metal wiring layers. A color filter array 100 (eg, including red filter 100a, green filter 100b, and / or blue filter 100c) is formed on and / or over the upper interlayer dielectric layer. Flattening layer 200 is formed on and / or over color filter array 100 and compensates for height differences between different filters.

[0020] Accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com