A kind of preparation method of porous polymer semipermeable membrane and product thereof

A polymer semipermeable membrane and polymer technology, which is applied in the field of porous polymer semipermeable membrane preparation, can solve the problems of reducing the stability of the sensor, inconvenient membrane thickness, and difficulty in ensuring the consistency of the same batch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

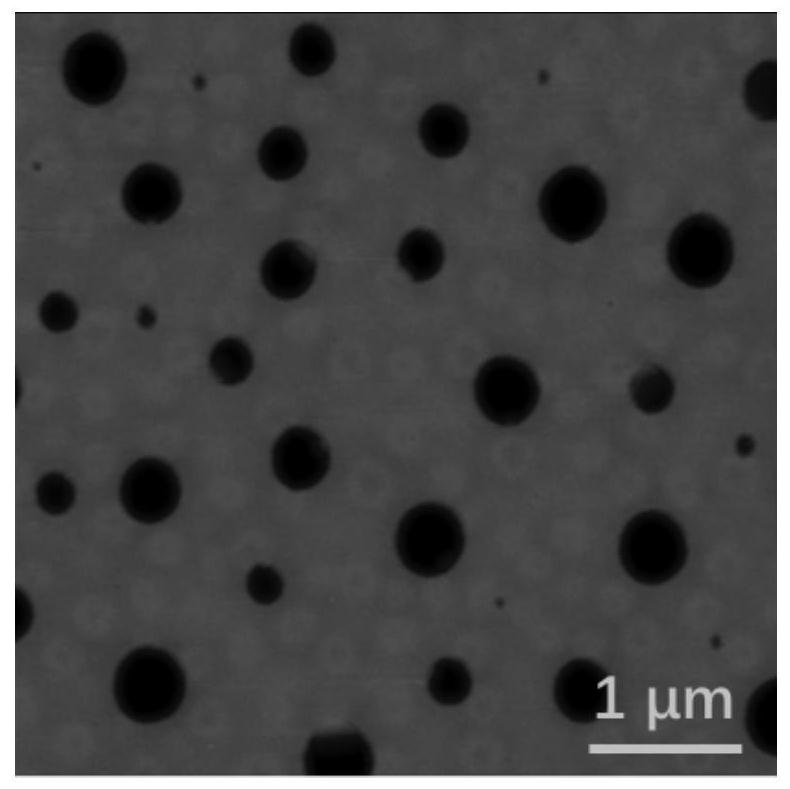

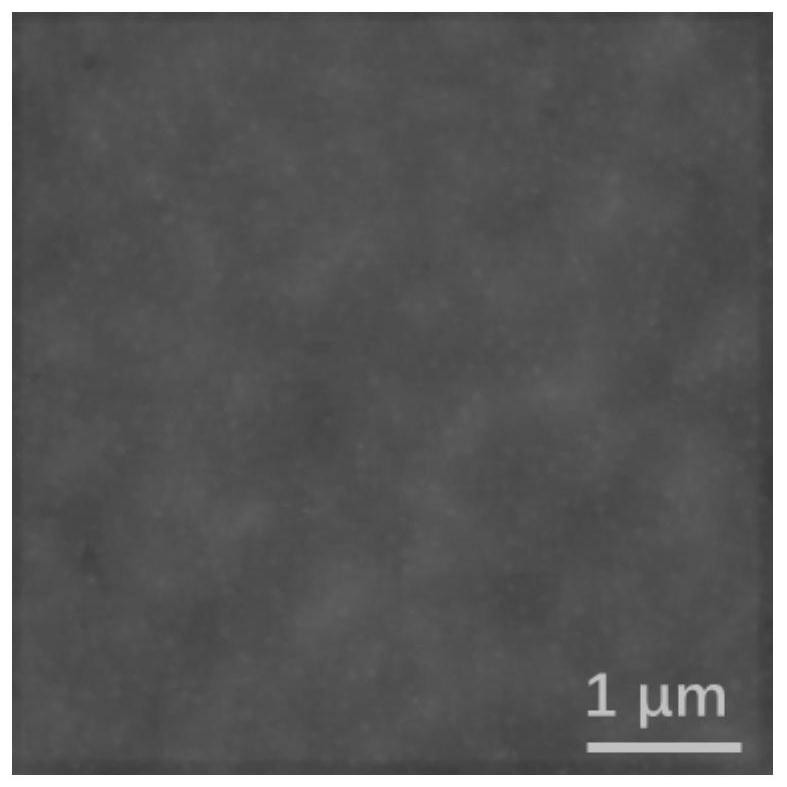

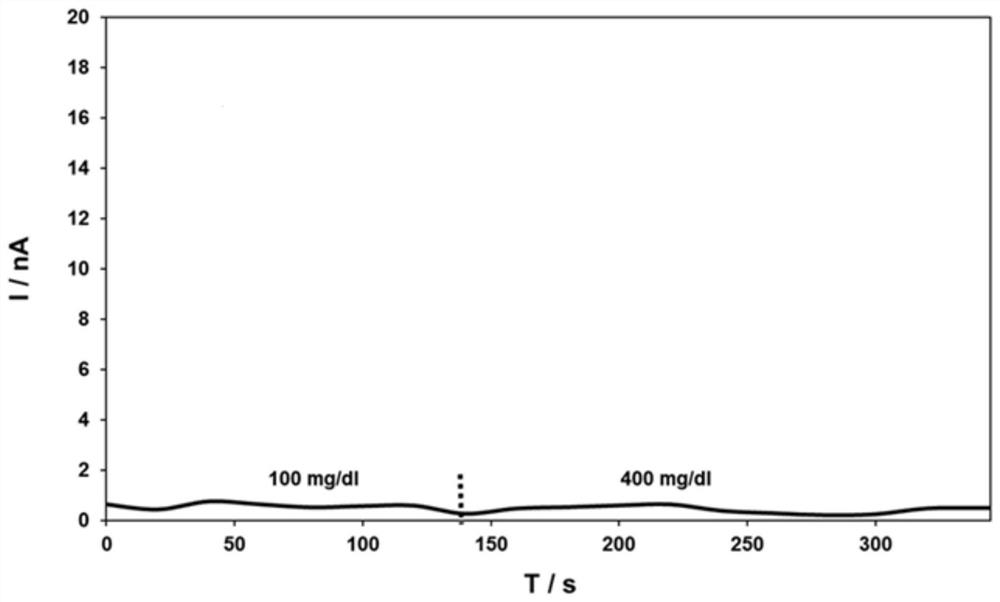

[0028] Embodiment 1 of the present invention: a preparation method of a porous polymer semipermeable membrane:

[0029] Poly-N-butyloxanorborneneimide (molecular weight is 100000g / mol) and pentaerythritol tetramercaptoacetate (molar ratio C=C:-SH=1:4) in tetrahydrofuran / n-butanol (V THF :V n-Butanol =1:4) Dissolve in the mixed solvent to form a coating solution (the mass percentage concentration of polymer poly-N-butyloxanorborneneimide is 10%); immerse the biosensor in the coating solution, 30°C Then, a layer of polymer film was coated on the electrode surface of the biosensor by the pulling method; dried at 30 °C for 60 minutes, the hydrophobic component and the hydrophilic component were separated during this process; the polymer film was subjected to UV cross-linking. , UV wavelength 365nm, energy density 25mW cm -2 After cross-linking, the biosensor was immersed in n-butanol for 1 minute to remove unreacted pentaerythritol tetramercaptoacetate, and dried at 30°C for 60 ...

Embodiment 2

[0030] Embodiment 2: A kind of preparation method of porous polymer semipermeable membrane:

[0031] (molecular weight is 50000g / mol) and (molar ratio C=C:-SH=1:20) in tetrahydrofuran / isopropanol (V THF :V iso-propanol =1:1) Dissolved in mixed solvent to form coating solution (polymer The mass percentage concentration of 10%); the surface of the biosensor electrode was coated with a doctor blade at 25 °C; dried at 30 °C for 30 minutes, the hydrophobic component and the hydrophilic component were separated during this process; The film is UV cross-linked, the UV cross-linking wavelength is 254 nm, and the energy density is 25 mW cm -2 , the cross-linking time was 6 minutes; after cross-linking, the sensor was immersed in ethanol for 1 minute to remove unreacted After drying at 30°C for 120 minutes again, a porous polymer semipermeable membrane with a thickness of 13 μm was obtained.

Embodiment 3

[0032] Embodiment 3: A kind of preparation method of porous polymer semipermeable membrane:

[0033] (molecular weight is 20000g / mol) and (molar ratio C=C:-SH=1:2) dissolved in isopropanol solvent to form a coating solution (polymer The mass percentage concentration of 2%); spin coating on the surface of the biosensor electrode at 20 °C; drying at 40 °C for 30 minutes, during this process, the hydrophobic component and the hydrophilic component are separated; The film was cross-linked by heating and cross-linked at 80 °C for 1 hour; after cross-linking, the sensor was immersed in ethanol for 10 seconds to remove unreacted After drying at 40° C. for 60 minutes, a porous polymer semipermeable membrane with a thickness of 350 nm was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com