Offset air current powder needle split charging head device

An offset, airflow technology, applied in the directions of packaging, transportation and packaging, and the type of packaged items, can solve the problems of the large outer circle size of the airflow powder needle dispensing head, the large size of the machine, and the large workload of the powder cartridge. To achieve the effect of easy cleaning of the powder cartridge and metering brush, reduced weight and small moment of inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

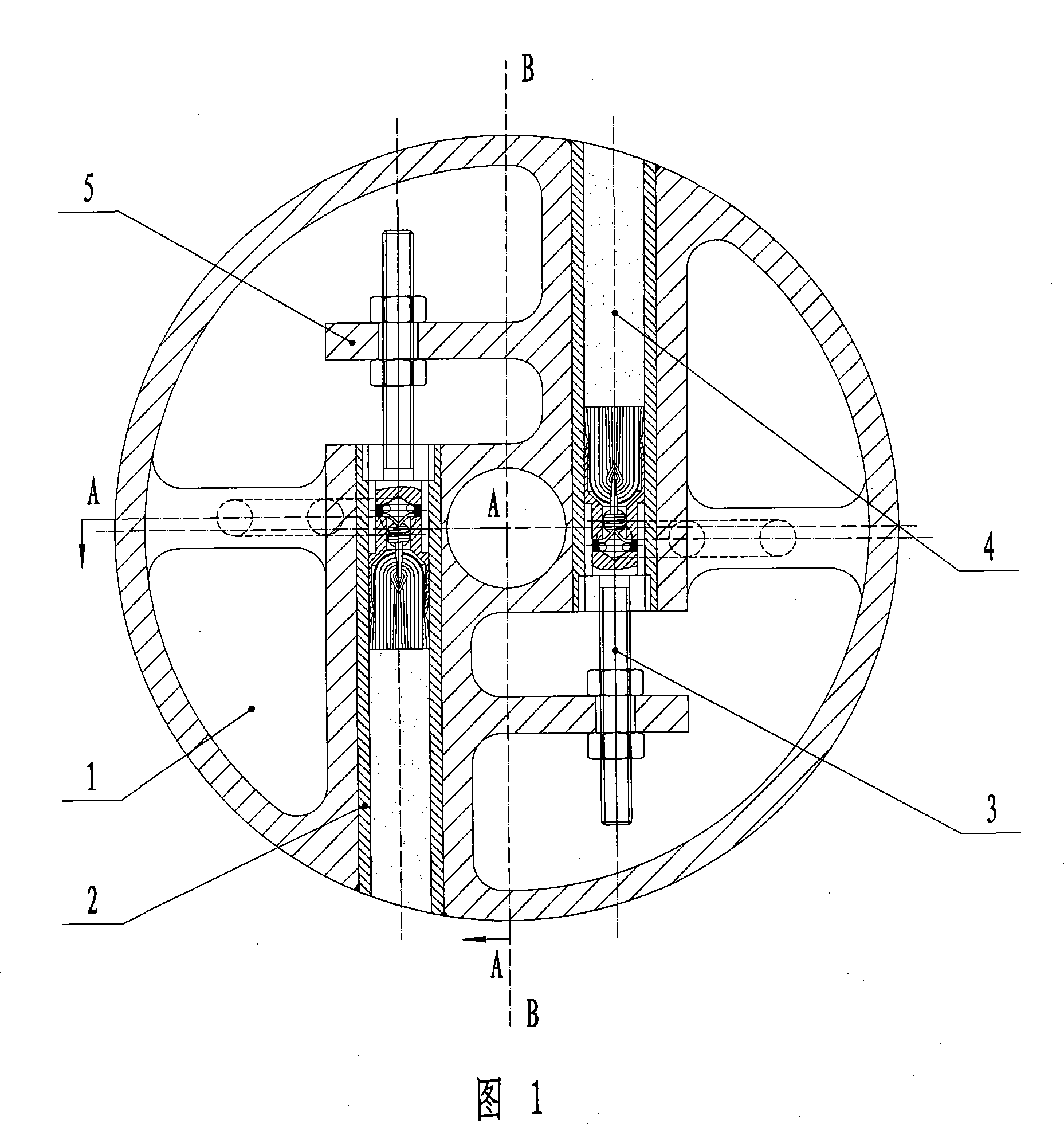

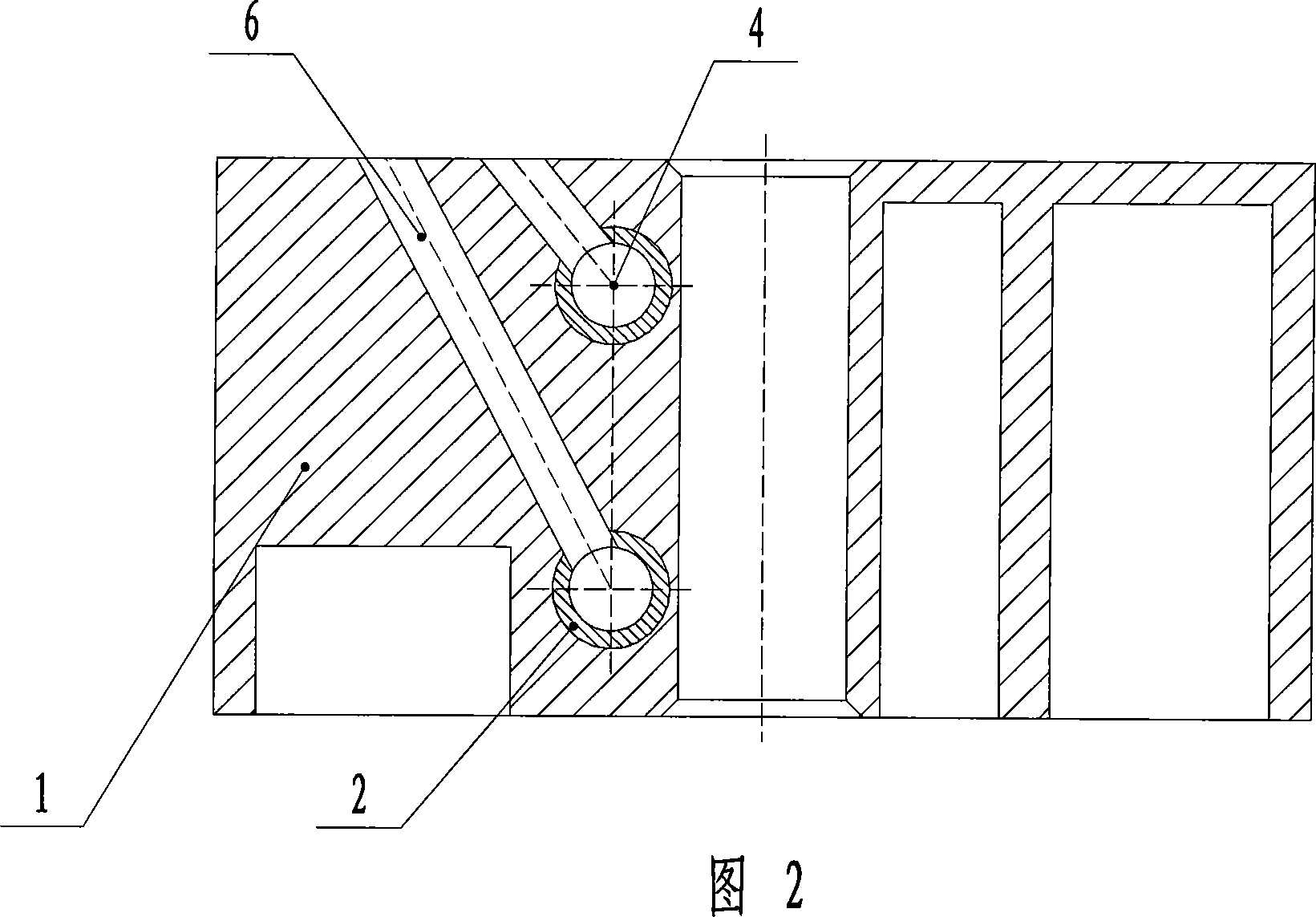

[0019] Example 1: As shown in Figure 1 and Figure 2, the line BB in the figure is the radial centerline of the airflow powder injection dispensing head 1. The axis of the powder cylinder 4 of the airflow powder injection dispensing head 1 is based on the airflow powder injection dispensing head 1. The BB line of the mounting head 1 is parallel to the center reference line, and the upper and lower lines are equally offset. That is to say, the circumference of the air jet powder injection dispensing head is divided into two powder cylinders 4 at 180°, which is suitable for use on a single-row powder injection dispensing machine that dispenses one bottle at a time.

Embodiment 2

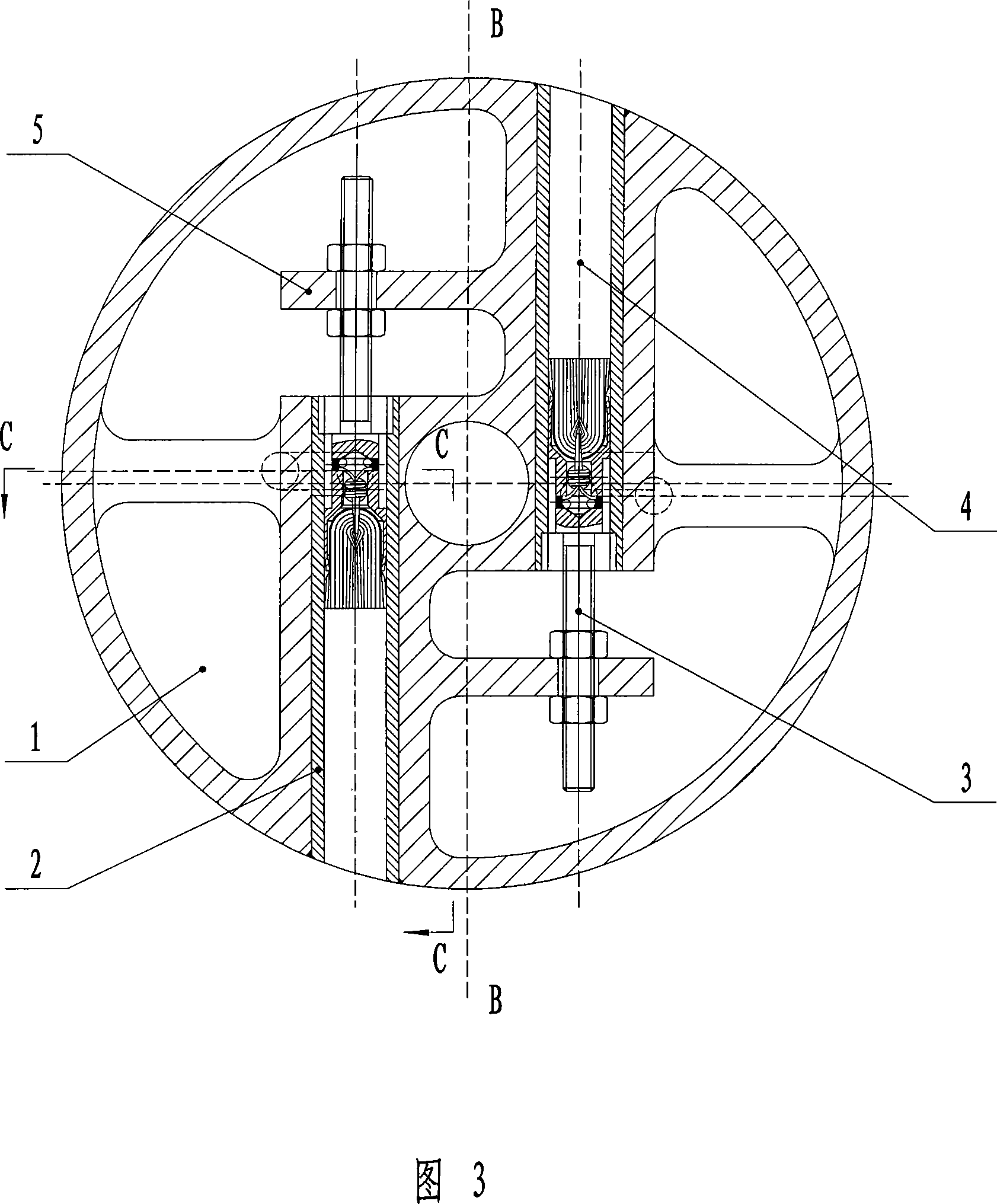

[0020] Example 2: As shown in Fig. 3 and Fig. 4, the axis line of the powder cylinder 4 of the airflow powder injection dispensing head 1 is centered on the BB line of the airflow powder injection dispensing head 1 and the reference lines are parallel to each other. It means that two pairs of powder cylinders 4 are divided equally at 180° on the circumference of the airflow powder injection dispensing head 1. It is suitable for use on a double-row powder injection dispensing machine that dispenses two bottles at a time. The machine uses star wheel intermittent bottle feeding, it feeds two bottles at a time, so the central connecting line of the two powder cartridges 4 is parallel to the axis line of the airflow powder injection dispensing head 1, and the center distance is parallel to the matching bottle feeding star. The pitches of the gear teeth are equal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com