Method and device for realizing double-component coat on SiC fibre surface

A fiber surface, two-component technology, applied in the field of deep processing of SiC fibers, can solve the problems of low efficiency and high cost, and achieve the effects of stable technical performance, strict thickness control, and stable and firm layer combination.

Inactive Publication Date: 2010-12-01

魏永芬

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The current technical means are only reprocessing with the help of the existing production process and equipment of SiC fiber, which is high in cost and low in efficiency.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

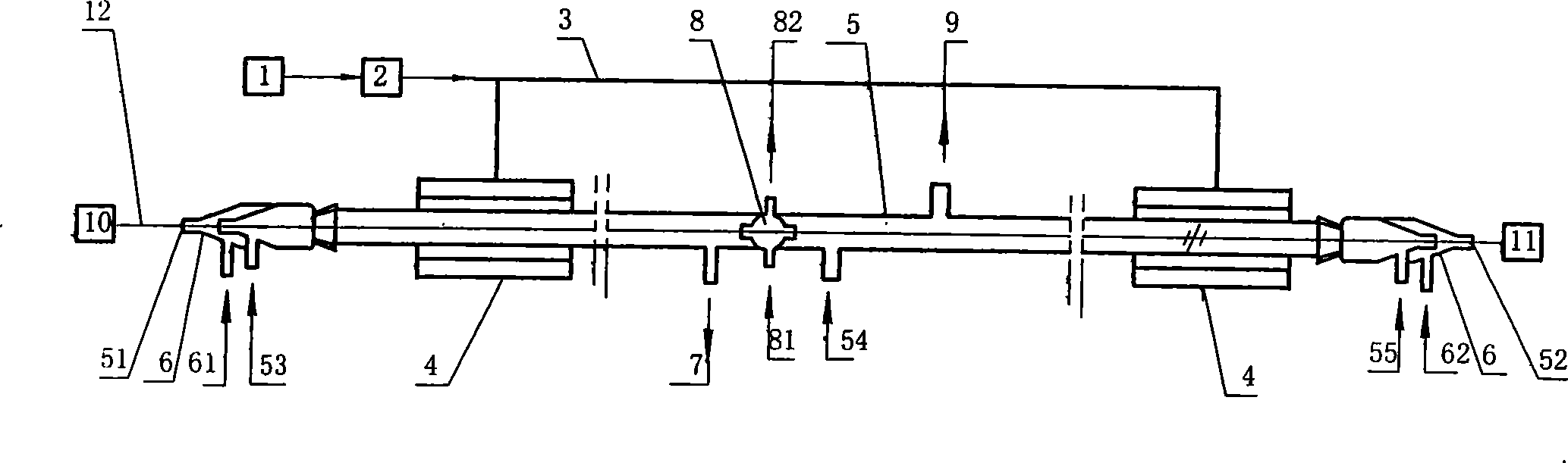

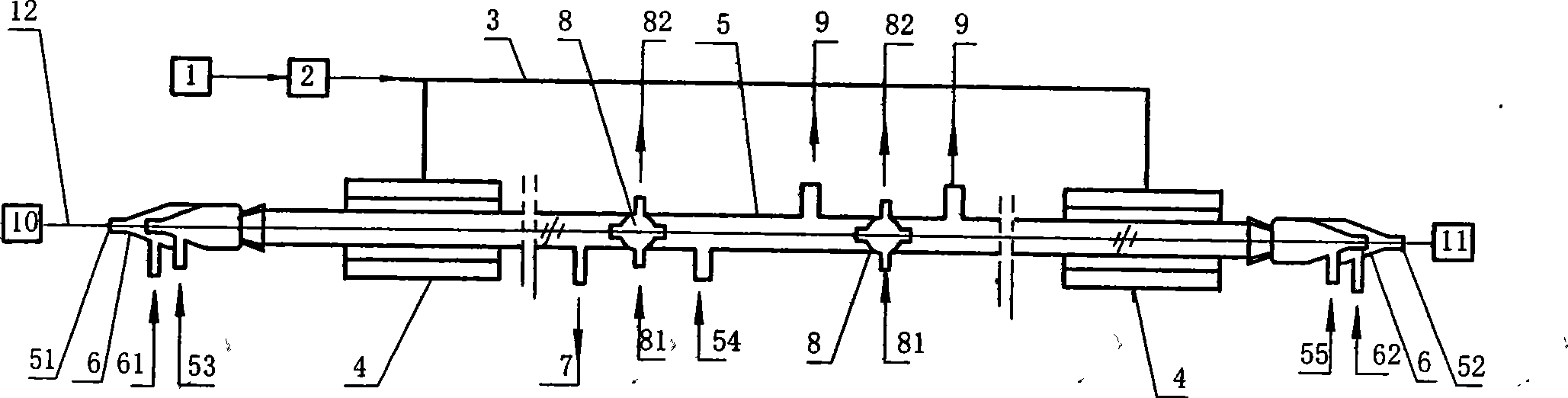

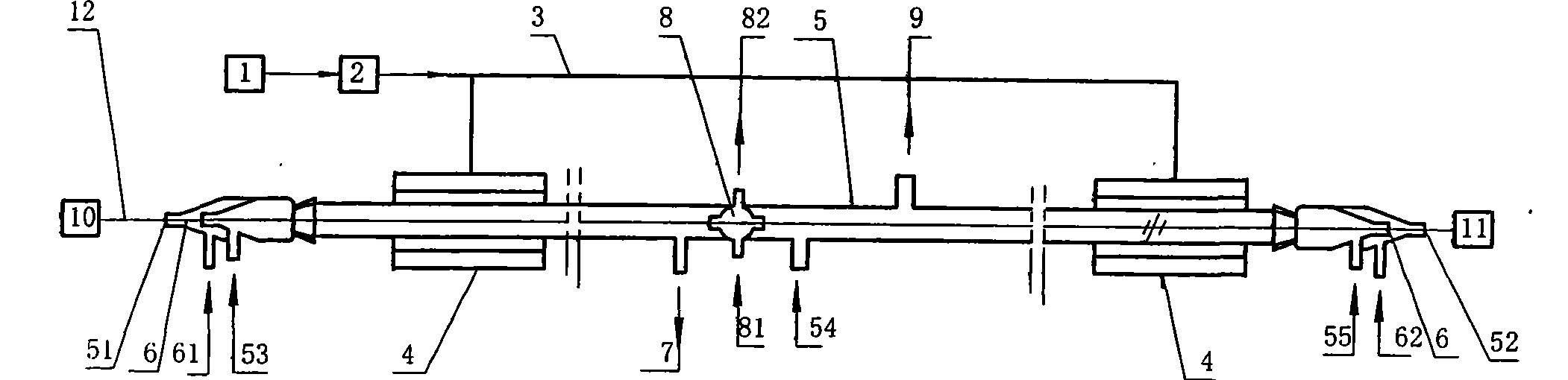

The present invention relates to a method and a device to realize double-set separating coating on the surface of SiC cellulose, which belongs to the deep working region to SiC cellulose. The method relies on a radio and focalizing heating device to heat a tungsten filament in the movement, and then uses the gas-phase deposit method to produce SiC cellulose; the technical process is: (1) the quartz tube heat reaction device is changed into three sealing separating zones; (2) the tungsten filament heated by a radio electric field passes through the three gas-phase deposit zones in turn; (3) SiC is deposited in the Zone I and then forms SiC cellulose level on the surface of the tungsten filament; (4) an inner coating component deposit is designed inside of Zone II and then is on the surfaceof SiC cellulose level; (5) an outer coating component deposit is designed inside of Zone III and then is on the surface of inner coating of SiC cellulose level. The matched special device is an improvement to the quartz tube heat reaction device in the radio and focalizing heating device; in particular to a double-directional sealing argon seal is arranged in the quartz tube reaction device; a discharge mouth for the gas after being reacted is arranged on the front part of the seal; and an intake mouth for the mixing gases to be reacted and a discharge mouth for the gas after being reacted are arranged on the rear part of the seal.

Description

Method and device for realizing two-component coating on SiC fiber surface technical field The invention relates to the technology of deep processing SiC fiber. Specifically, it is a method and device for realizing two-component coating on the surface of SiC fiber Background technique SiC fiber has become the first choice for high-strength composite materials due to its unique high specific strength and high elastic modulus, and has been widely used. Especially in the field of aviation and aerospace, especially in the military industry, it occupies a special position. But its price is too expensive, it can only be used as the skeleton of composite materials. In order to improve its bonding strength with composite substrates, such as titanium, the surface of SiC fibers must be coated with an excessive layer of iron. In order to improve its absorption performance of high-frequency electromagnetic waves, a carbon coating is applied to its surface. If it is required to hav...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C03C25/22C22C47/04

Inventor 魏永芬

Owner 魏永芬

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com