Aluminium bus vertical casting technology method

A casting process and aluminum bus bar technology, which is applied in the field of aluminum bus bar vertical casting process, can solve the problems of high production cost, complex process manufacturing, uneven current, etc., and achieve the effect of improving product qualification rate and reducing manufacturing cost

Inactive Publication Date: 2008-02-20

GUIZHOU BRANCH CHINA ALUMINUM IND

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the past, rolling and calendering busbars were used in electrolytic cell aluminum busbars, which had a series of disadvantages: complex manufacturing process, high energy consumption, serious anisotropy, uneven current, high connection voltage and high production costs, etc.

But its production technology is difficult to master, and the product quality is unstable

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0013] Please write the specific name of the casting equipment, control the pressure of the cooling water at 0.8~1.0kg / cm during casting 2 (Pump head H=32m, flow Q=100m 3 / h).

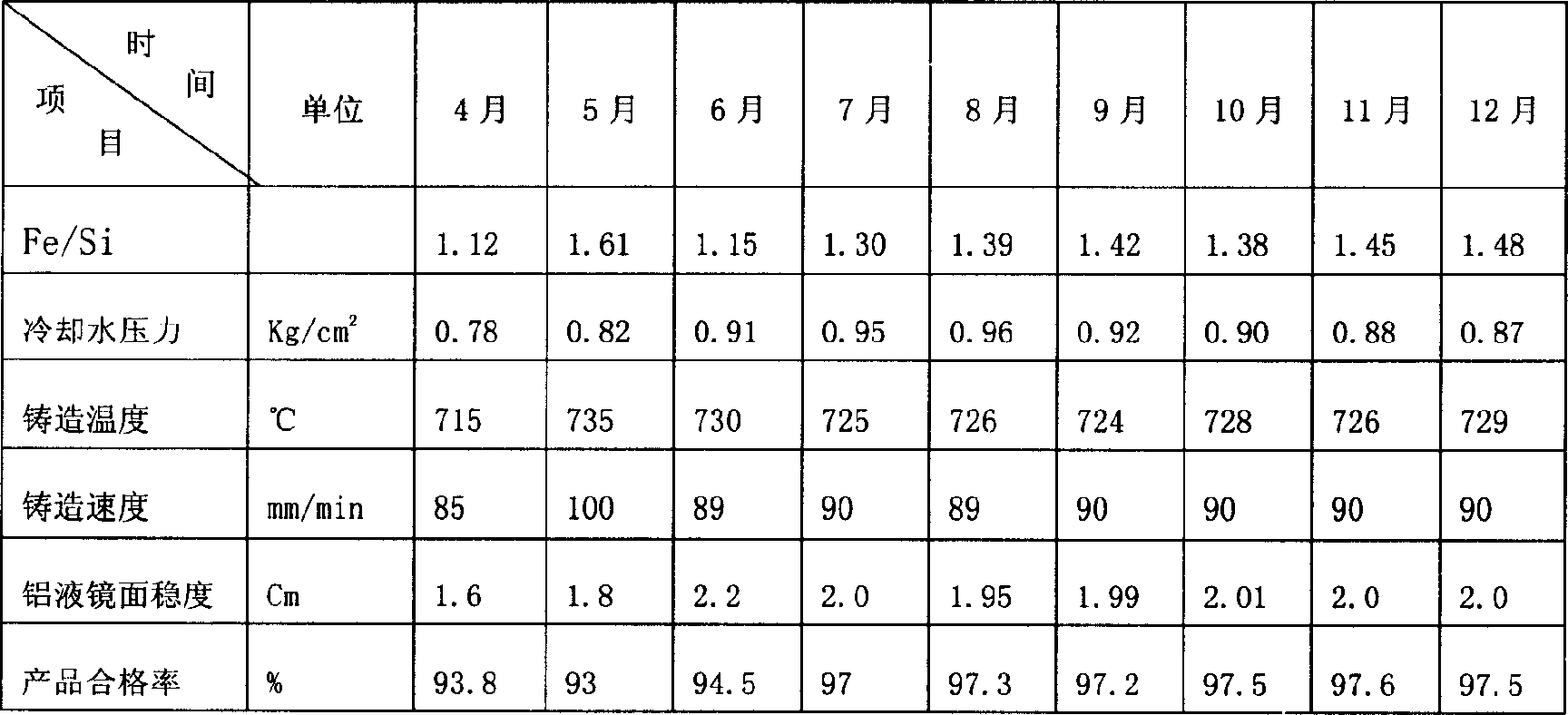

[0014] Table 1 List of cast aluminum bus bar Fe / Si, process parameters and product pass rate

[0015]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The present invention relates to a technical method for vertical casting of aluminum bus. By adopting the technique of vertical casting the invention is characterzied in that the technological parameters in production are as follows: 1) aluminum content in aluminum liquid used in casting is more than 99.65 percent, content of impurity is less than 0.35 percent, and ratio of Fe to Si is limited between 1.2 to 1.5; 2) casting termperature is limited between 720 to 730 DEG C; 3) casting speed is controlled between 80 to 100mm per minute; 4) the distant between level of the aluminum liquid and the upper inner rim of crystallizer is 2.0cm. The present method can remarkably improve the passing rate of product. In practical production, the present method can control heat crack, curve and twist of the aluminum bus and can reduce the production cost of the aluminum bus.

Description

technical field [0001] The invention relates to a vertical casting process for aluminum busbars. Background technique [0002] A large number of high-quality aluminum conductive busbars are required in electrolytic production, and their quality directly affects the operation safety of the electrolytic cell infrastructure installation and production power consumption indicators. In the past, rolling and calendering busbars were used in the aluminum busbars of the electrolytic cell. It has a series of disadvantages: complex manufacturing process, high energy consumption, serious anisotropy, uneven current, high connection voltage and high production cost. In recent years, with the development of large-scale aluminum electrolytic cells, the cathode busbar, anode busbar, and column busbar all adopt large-section cast aluminum busbars. This product has high mechanical strength, easy processing, low current density, and easy current sharing. And many advantages such as energy sav...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22D25/02B22D21/04

Inventor 党步军李希明成庚张涛

Owner GUIZHOU BRANCH CHINA ALUMINUM IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com