Method for manufacturing macromolecular composite door

A manufacturing method and technology for composite doors, which are applied in manufacturing tools, ceramic molding workshops, ceramic molding machines, etc., can solve the problems of national resource waste, transportation, inconvenient installation, and cumbersomeness, saving wood, highlighting environmental protection factors, and reducing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

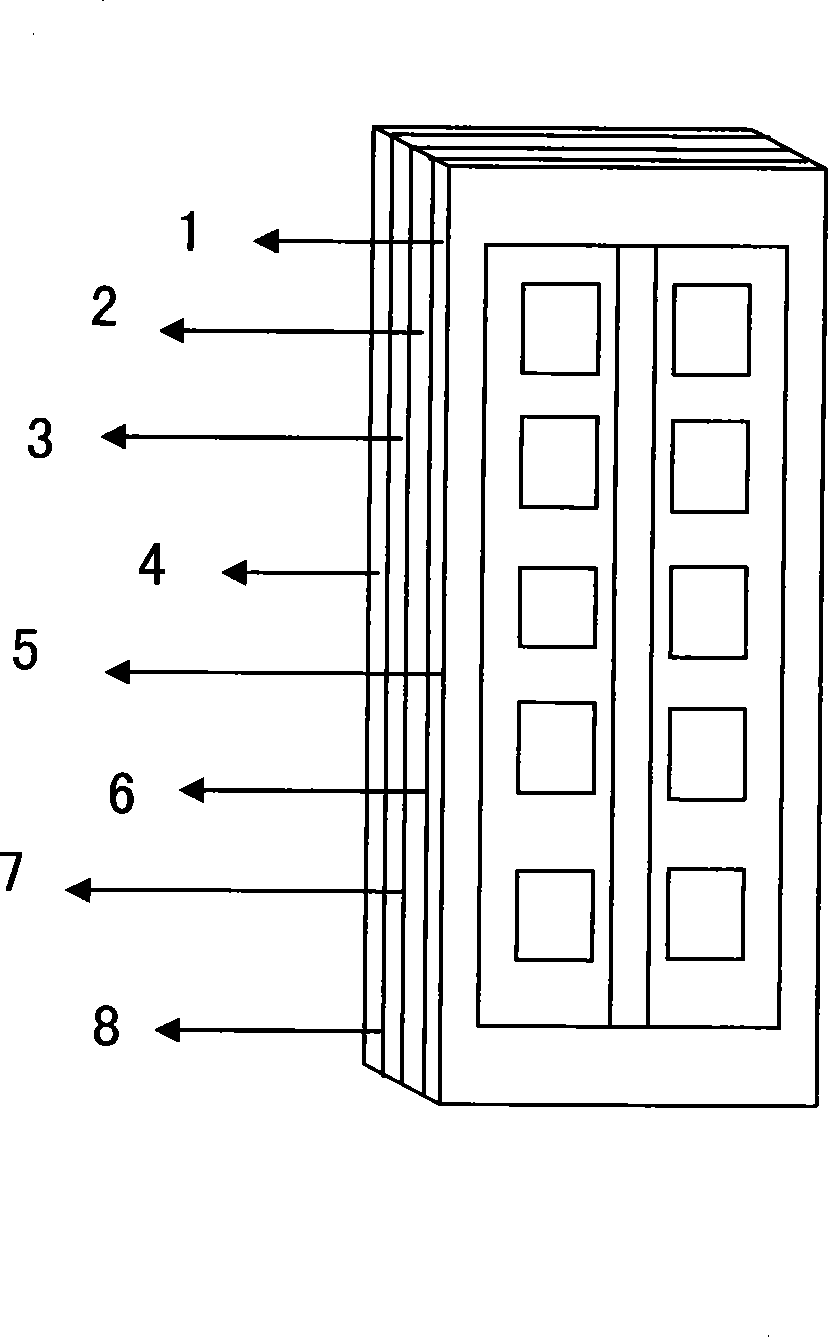

Image

Examples

Embodiment Construction

[0020] (1) Product raw material technical formula

[0021] 1. Formulation and preparation of release agent

[0022] (1) Release agent formula (a, b, c are mass ratios)

[0023] a washing powder 100

[0024] b engine oil 100

[0025] c water 6000

[0026] (2) Preparation: First dissolve the washing powder with a small amount of water, then add engine oil and stir well, then add the rest of the cold water.

[0027] Note: Shake well before each use.

[0028] 2. Mold formula and preparation (a, b, c are mass ratios)

[0029] (1) Mold formula:

[0031] b Magnesium chloride solution 100

[0032] c Silica 10

[0033] (2) Preparation:

[0034] 1, weigh the raw materials in proportion, mix all dry materials with about 80% magnesium chloride solution and stir evenly with a mixer;

[0035] II. Then add the remaining magnesium chloride solution and stir evenly before use.

[0036] 3. Product formula and preparation

[0037] (1) Product formula: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com