Sticking-free stiffening rib steel plate shearing force wall

A kind of steel plate shear wall, non-bonding technology, applied in the direction of wall, building components, anti-vibration, etc., can solve the problems of local buckling of stiffeners, loss of stiffeners, reduction of energy dissipation capacity, etc., to achieve full energy consumption hysteresis loop, prevent Overall buckling, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

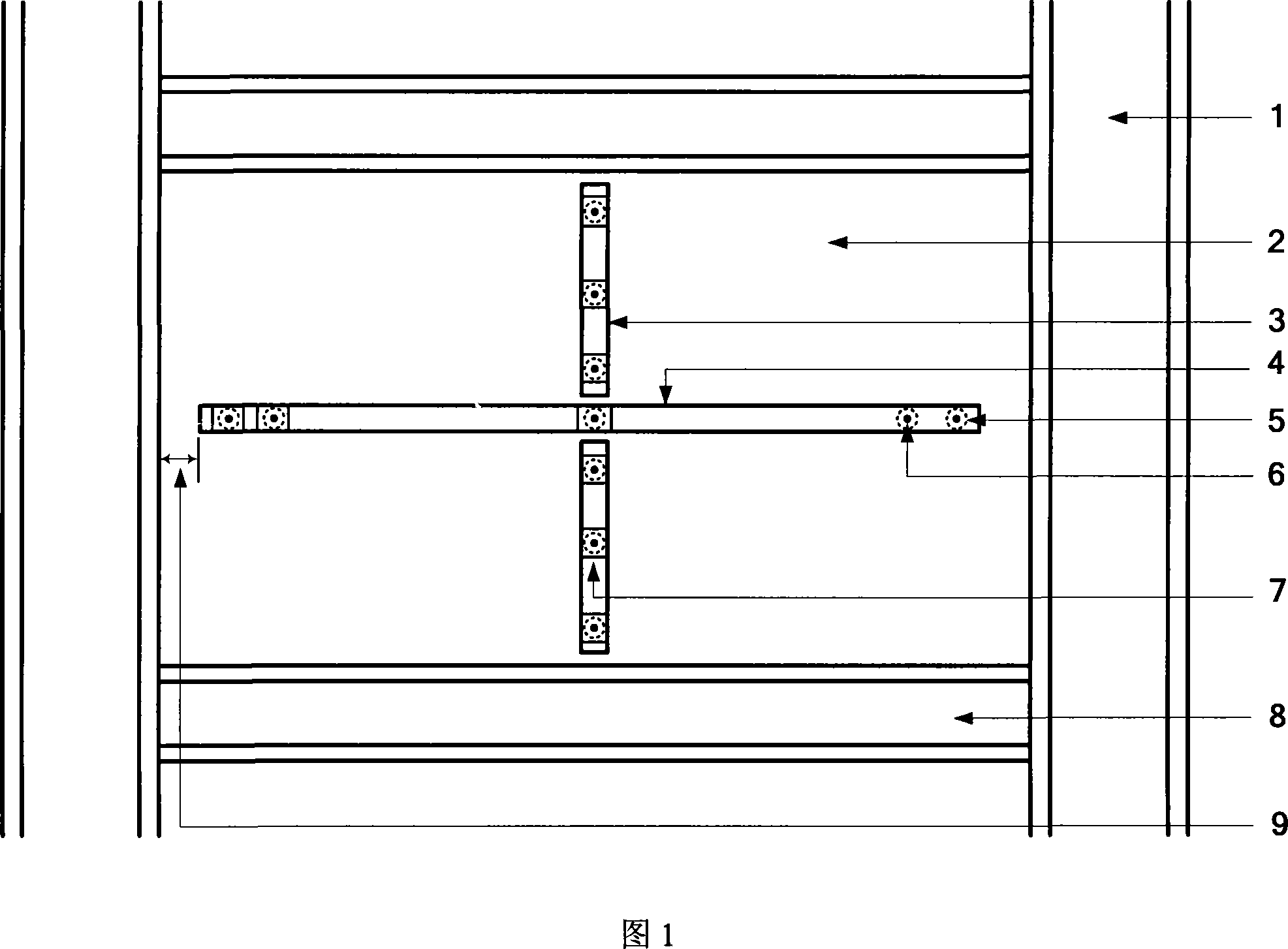

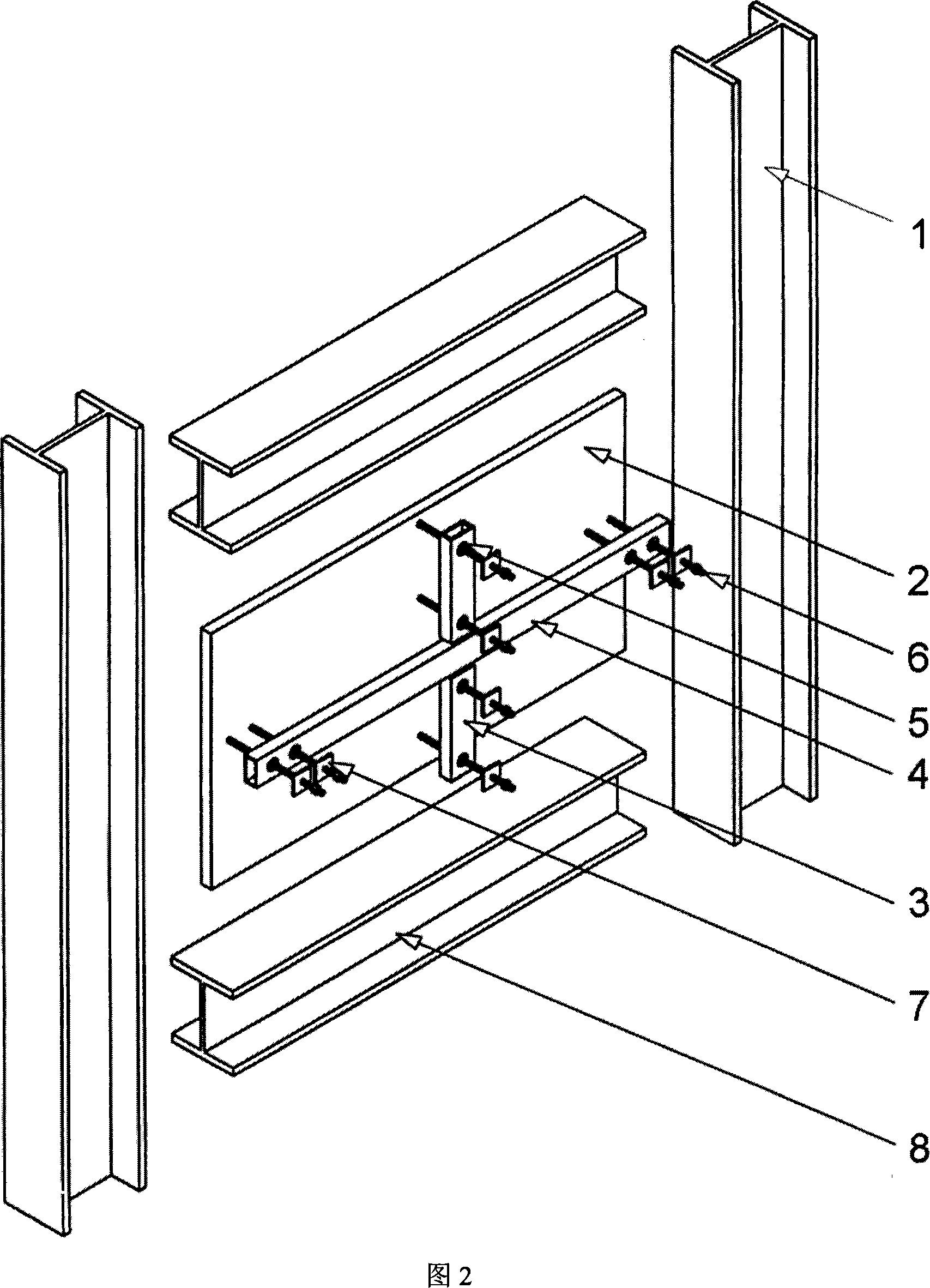

[0018] As shown in Figure 1-2:

[0019] 1- Edge frame post

[0020] 2- Embedded steel plate

[0021] 3- Vertical section steel stiffener

[0022] 4- Transverse section steel stiffener

[0023] 5- The large round hole reserved on the steel stiffener

[0024] 6-Connecting bolts between embedded steel plates and steel stiffeners

[0025] 7-Steel spacer between nut and steel stiffener

[0026] 8-edge frame beam

[0027] 9-Gap between edge member and steel stiffener

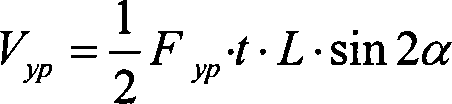

[0028] The non-bonded stiffened steel plate wall of the present invention is composed of embedded steel plates, steel plate front and rear section steel stiffeners and edge components; the edge components are composed of edge columns 1 and edge beams 8, and the embedded steel plates 2 are made of low yield point high ductility steel or high strength High ductility steel; the front and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com