Outer inflatable engine

An engine and air-inflated technology, which is applied in the direction of engine components, combustion engines, machines/engines, etc., can solve the problems of engine output power drop, mechanical loss, aerodynamic loss, reduction of intake air volume and waste in a single suction stroke, and achieve The effect of increasing power per liter, reducing emissions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

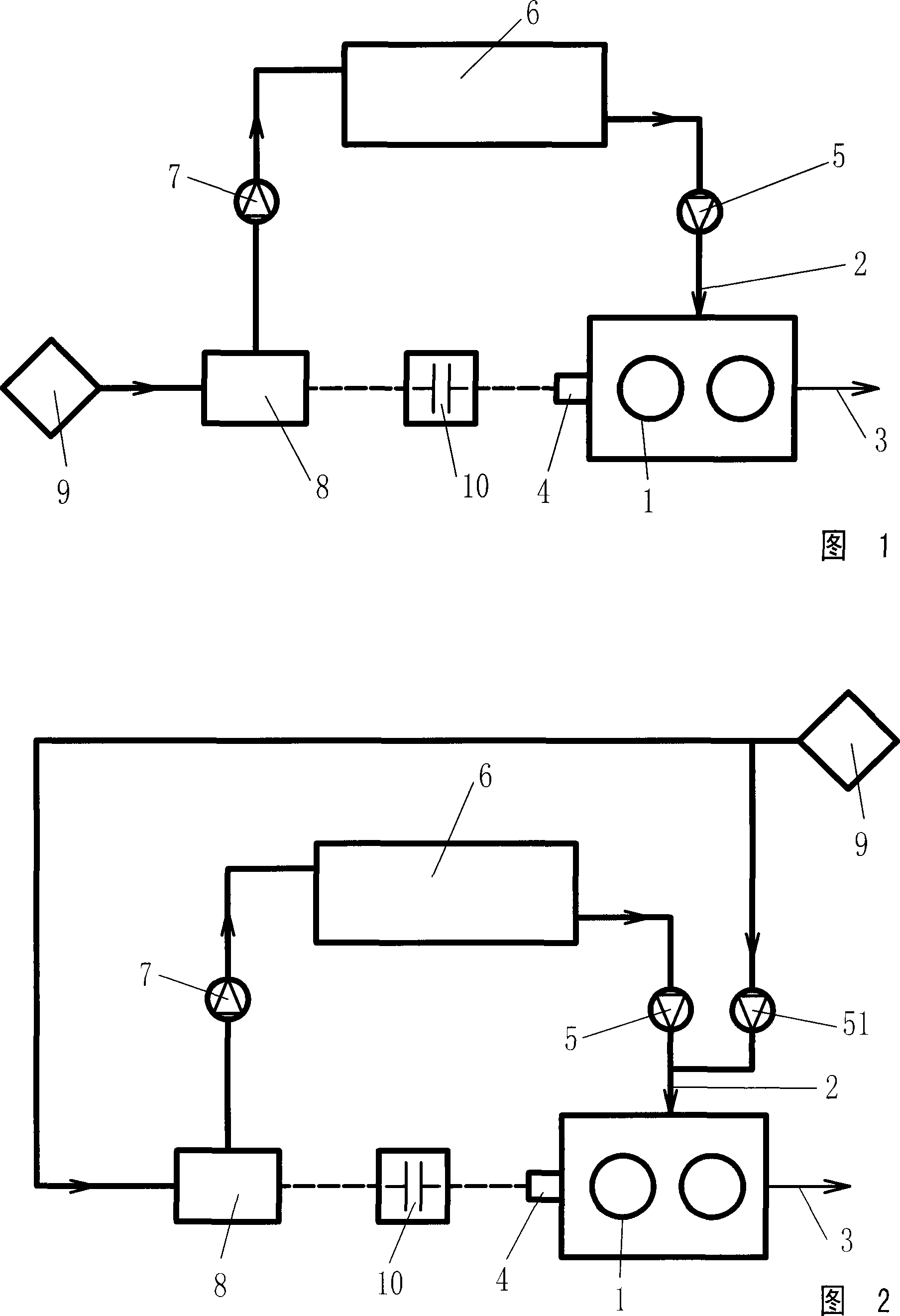

Embodiment 1

[0048] The externally charged engine as shown in Figure 1 includes a cylinder 1, an air inlet 2, an exhaust 3, and a crankshaft 4, and the air inlet of the cylinder 1 communicates with the outlet of the air storage tank 6 through the control device 5, and the The inlet of the air storage tank 6 is communicated with the compressed air outlet of the air compressor 8 through the control device 7, the air inlet of the air compressor 8 is communicated with the intake system 9, and the power input shaft of the air compressor 8 is directly or via The clutch 10 is connected with the crankshaft 4 of the engine, and the camshaft and the crankshaft of the engine are set at constant speeds, that is, within the range of 360 degrees of crankshaft rotation, the engine completes high-pressure charging, secondary compression, work and exhaust processes.

Embodiment 2

[0050] The externally charged engine shown in Figure 2 is different from Embodiment 1 in that a control device 51 connected in parallel with the control device 5 is provided at the air inlet of the cylinder 1, and the control device 51 is connected with the intake port. Gas system 9 communicates, and the rotating speed of the camshaft of described engine is set as 1 / 2 of crankshaft rotating speed, namely within the range of 720 degree of crankshaft rotation, engine completes suction charging stroke, compression stroke, power stroke and exhaust stroke.

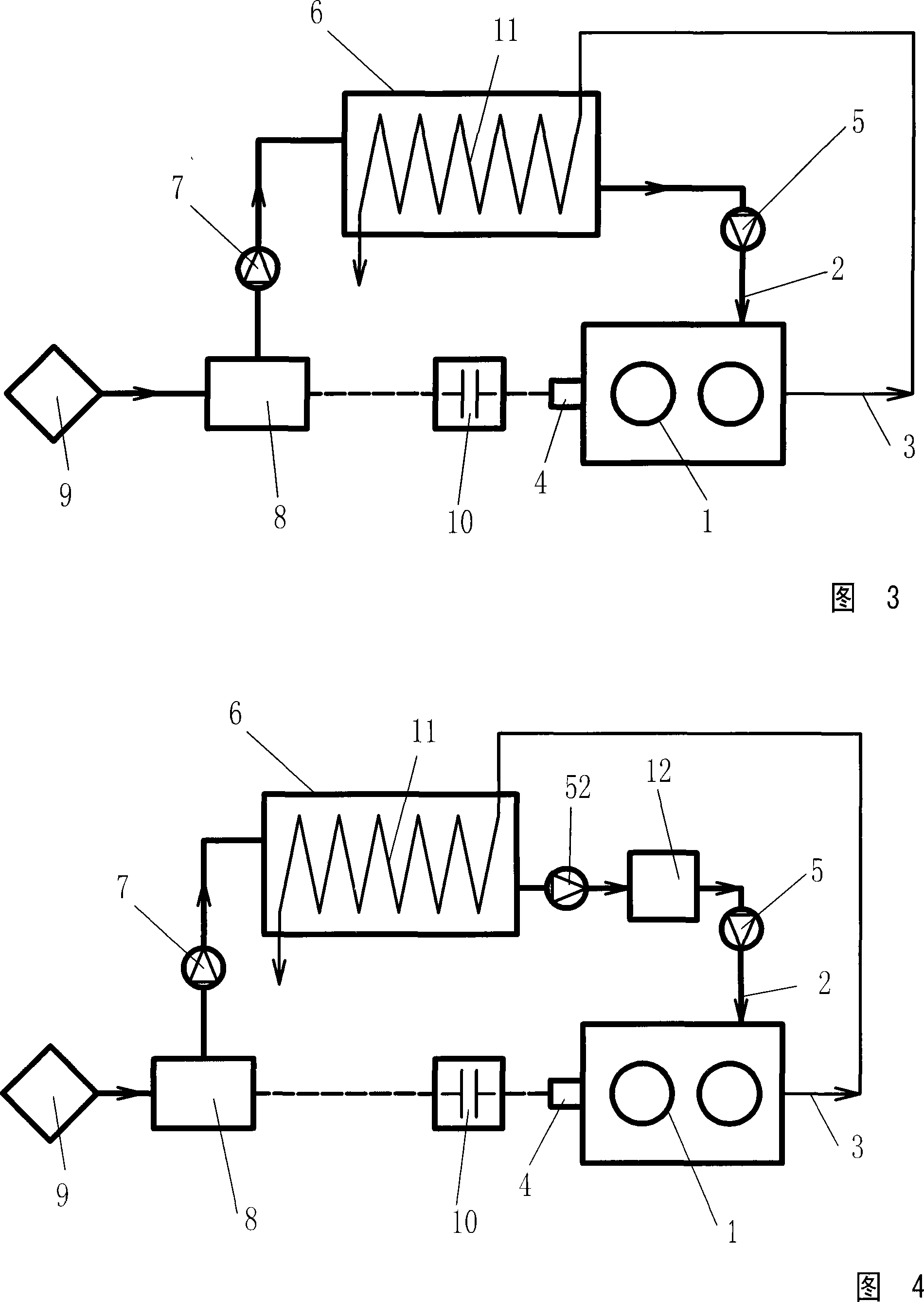

Embodiment 3

[0052] The difference between the externally charged engine shown in FIG. 3 and Embodiment 1 is that the exhaust passage 3 communicates with the heat exchanger 11 arranged in the air storage tank 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com