Magnetostrictive sensor for steel stranded wire supersonic guided wave detection

A technology of ultrasonic guided wave and magnetostriction, which is applied in the direction of using ultrasonic/sonic/infrasonic, generation of ultrasonic/sonic/infrasonic, and analysis of solids by using sound/ultrasonic/infrasonic, which can solve problems such as poor repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

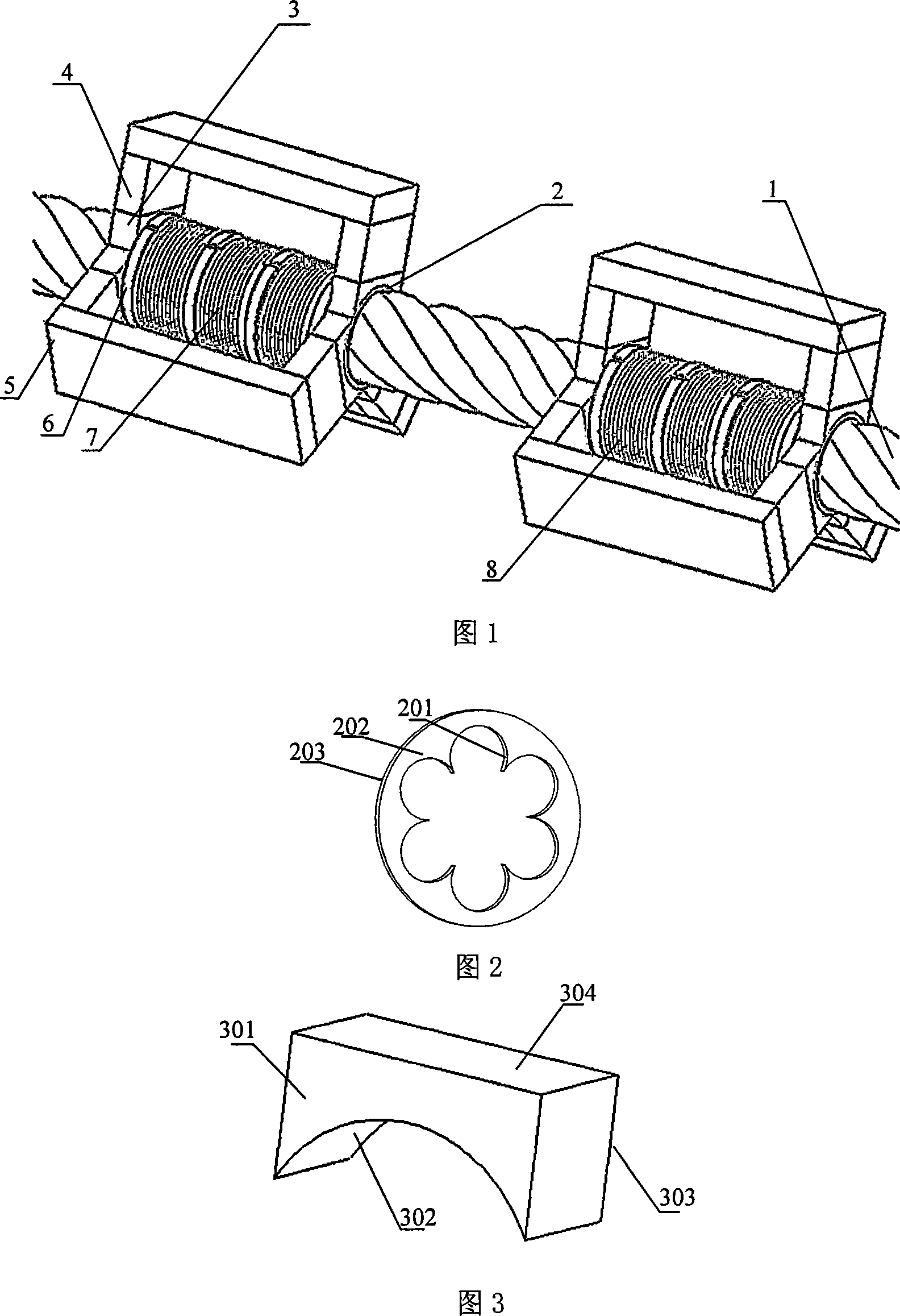

[0018] The present embodiment will be further described in detail below in conjunction with FIGS. 1 to 6 .

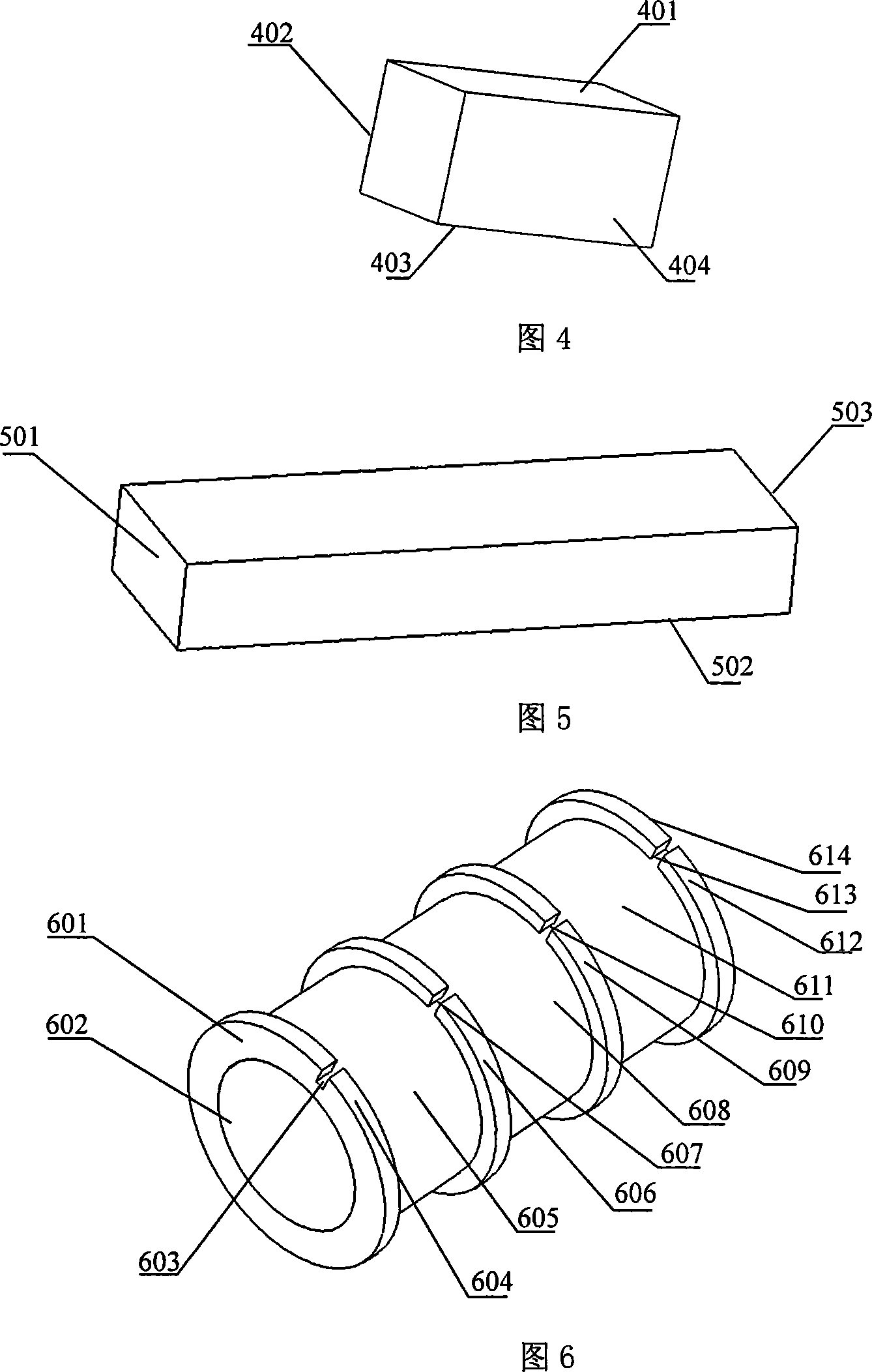

[0019] The technical solution of the magnetostrictive ultrasonic guided wave detection sensor provided in this embodiment mainly includes two technical solutions of the excitation end sensor and the receiving end sensor. The structure of the sensor at the excitation end is shown in Figures 1 to 6, including a clip 2, a saddle 3, a permanent magnet 4, a yoke 5 and a solenoid 6, and the saddle 3 has three lower parts with a 120-degree arc The groove is composed of a cuboid, and the radius of the arc is the same as that of the steel strand 1, as shown in FIG. 3 . Four steps are arranged on the outer surface of the solenoid 6, as shown in FIG. 6 .

[0020] Taking the detection of a 7-core steel strand as an example, the solenoid 6 is tightly placed on the steel strand 1 through the central through hole 602, and 10 sheets are stacked together to form a clip 2, which is clam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com