Water-cooling middle case turbocharging mechanism

A turbocharging and turbine impeller technology, applied in liquid cooling, mechanical equipment, engine components, etc., can solve problems such as functional aging and poor cooling of engine superchargers, so as to promote power, improve cooling effect, and maintain structural changes Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

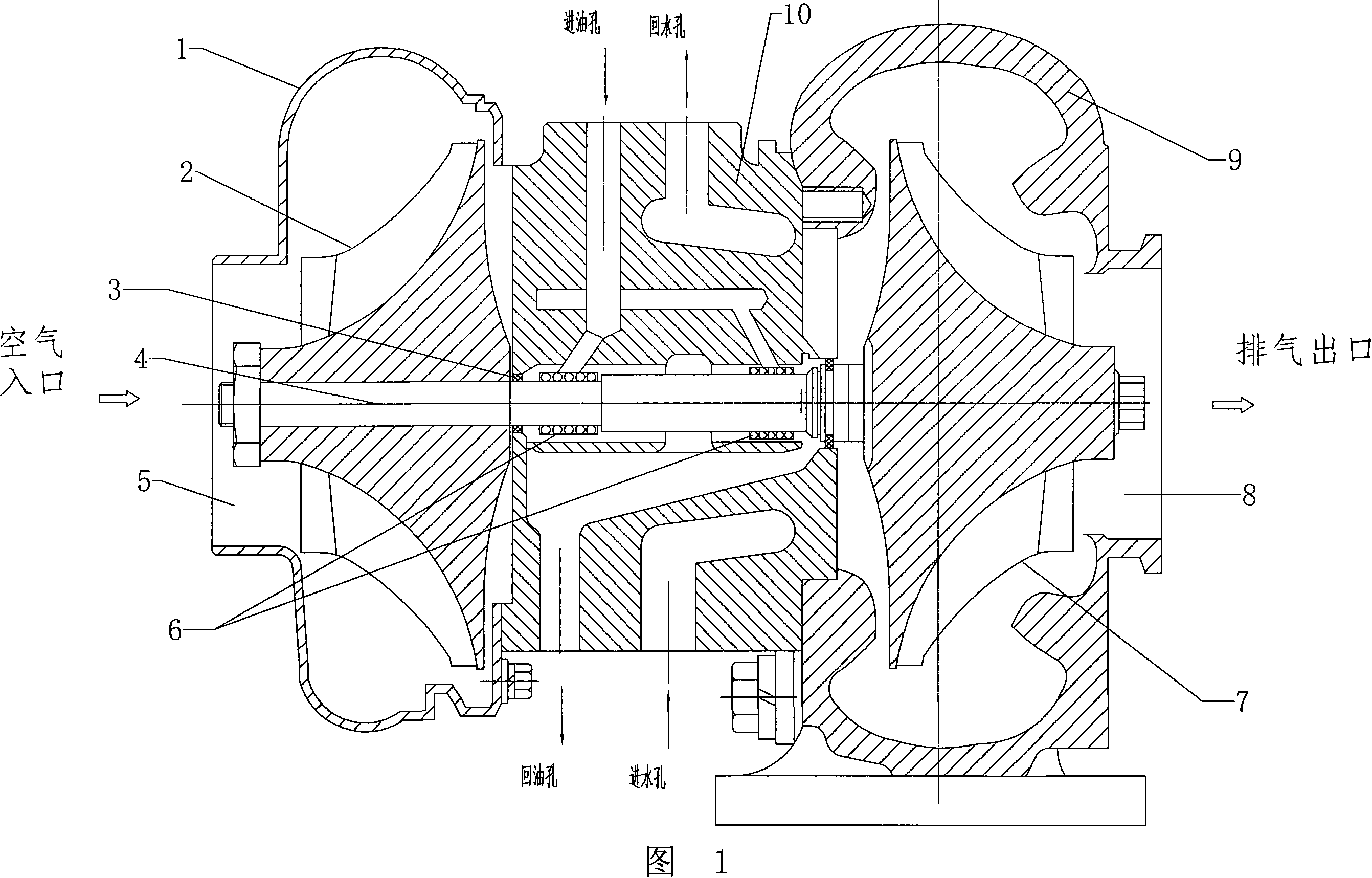

[0011] As shown in the figure: the compressor impeller 2 and the turbine impeller 7 are installed on the supercharger shaft 4, and it is characterized in that: there is a water-cooled intermediate shell 10 between the compressor impeller 2 and the turbine impeller 7, and on the water-cooled intermediate shell 10 A water inlet hole and a water return hole are provided, and the water inlet hole and the water return hole are communicated with each other by means of a passage arranged in the water-cooled middle shell 10, and cooling water enters the passage in the water-cooled middle casing 10 through the water inlet hole, and the water-cooled middle casing 10 After cooling, it is discharged from the return hole; there is a compressor pressure shell 1 outside the compressor impeller 2, and a turbine volute 9 outside the turbine impeller 2.

[0012] A floating bearing 6 is provided at the junction of the supercharger shaft 4 and the water-cooled middle case 10, and an oil inlet hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com