Aluminum alloy square ingot casting crystallizer

A technology for casting molds and aluminum alloys is applied in the field of continuous casting equipment in the metallurgical industry. , The effect of reducing secondary pollution and improving process quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

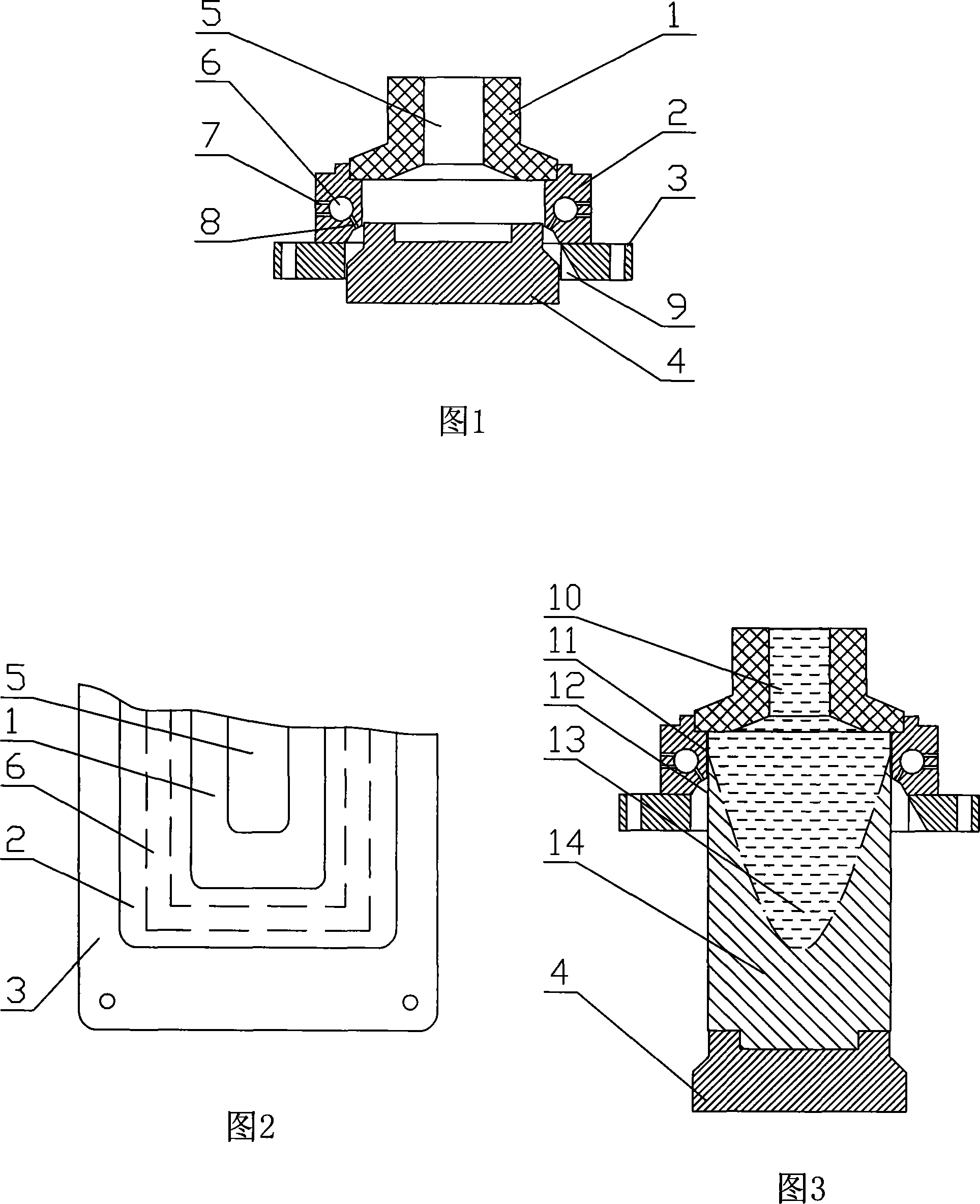

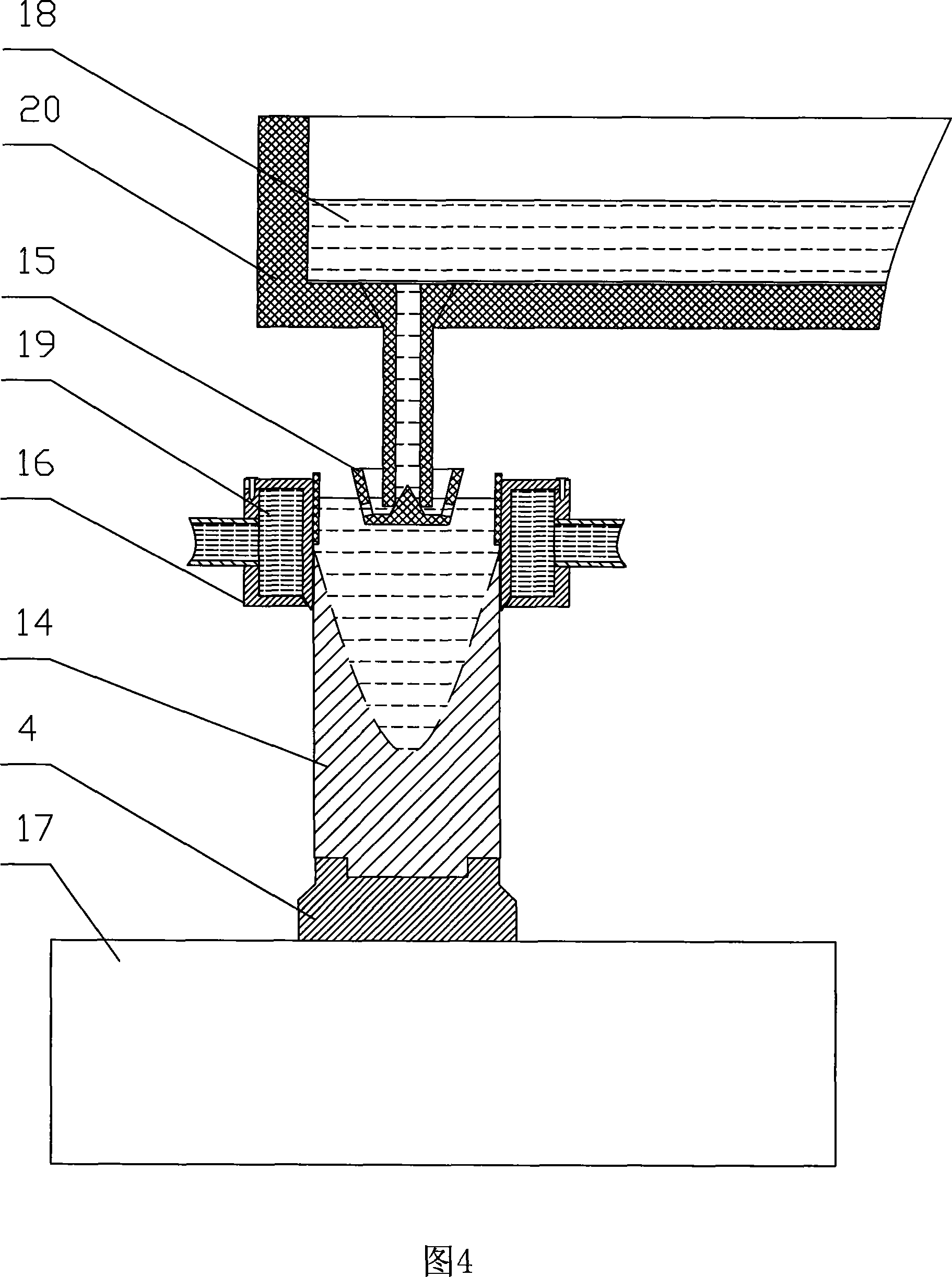

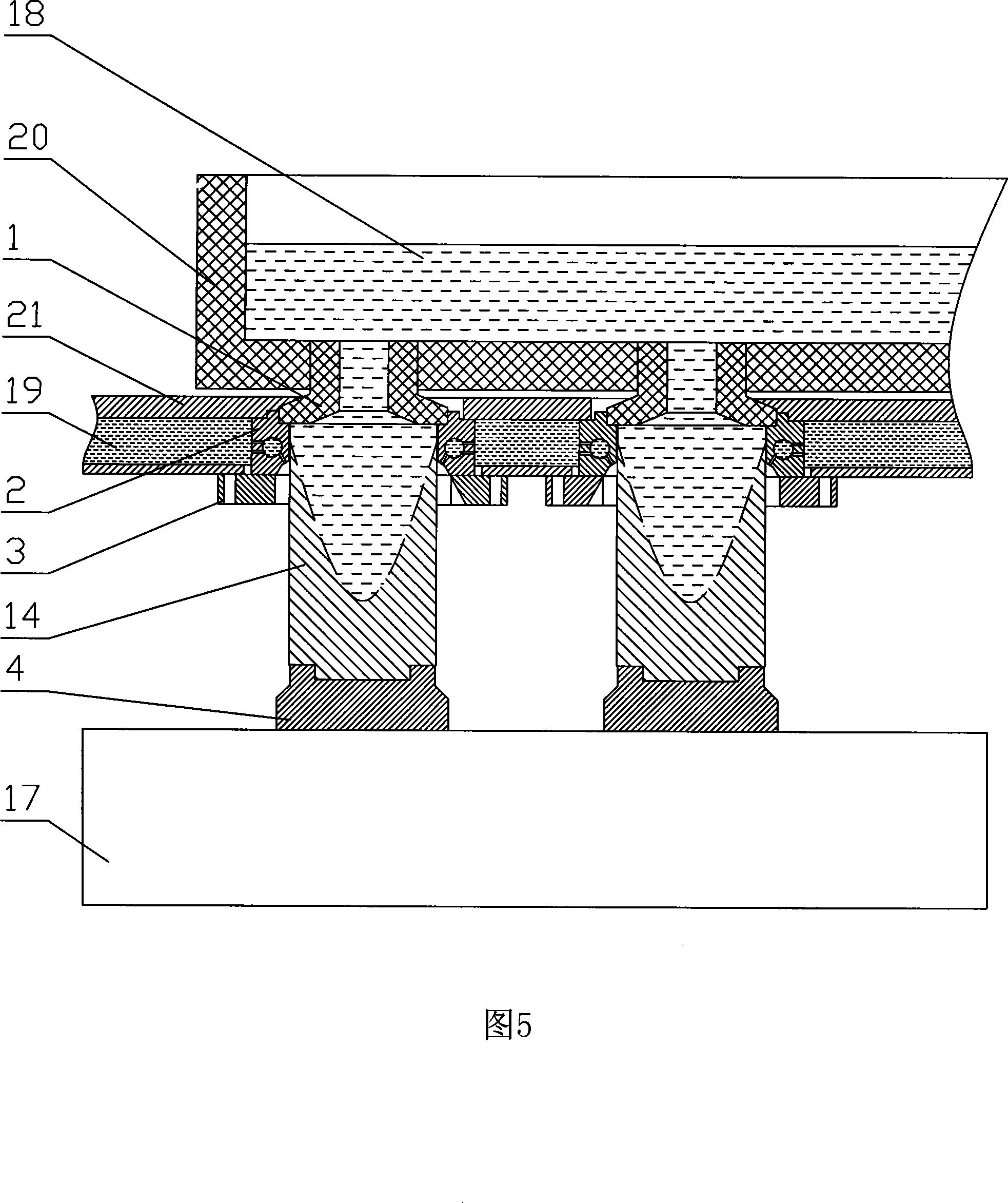

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0026] As shown in Fig. 1 and Fig. 2, the aluminum alloy square ingot casting crystallizer of the present invention is made up of thermal insulation hot roof guide tube 1, crystallizer upper cover 2 and crystallizer lower cover 3, thermal insulation hot top guide tube 1, The mold upper cover 2 and the crystallizer lower cover 3 are sequentially connected from top to bottom, and together with the dummy head 4 can form a liquid storage cavity. Insulation hot roof guide tube 1 is in the shape of a treasure cover, including a base and a guide tube. Determine the quantity and size according to the cross-sectional shape of the cast ingot, so as to achieve the purpose of evenly distributing the metal diversion liquid. In this embodiment, the diversion hole 5 is a square hole located at the center of the diversion tube, its cross-sectional shape is sim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com