High-temperature heat-storing device using concrete and heat storage method thereof

A technology of heat storage and concrete, which is applied in the field of solar energy utilization, can solve the problems of inability to achieve high temperature storage, unfavorable heat storage and heat release, loose accumulation of iron ore, etc., and achieve stable high temperature performance, low cost, and large heat storage capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

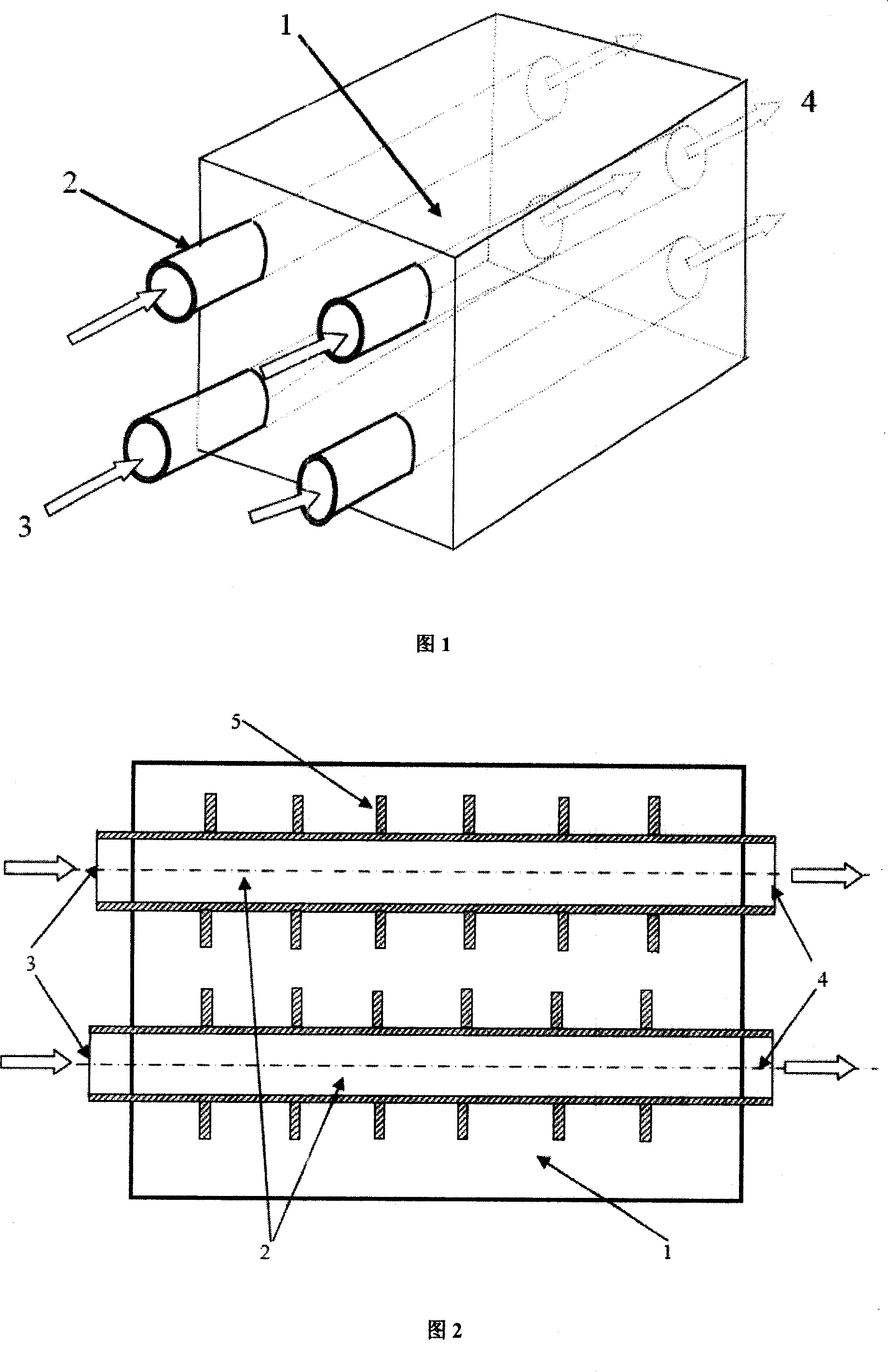

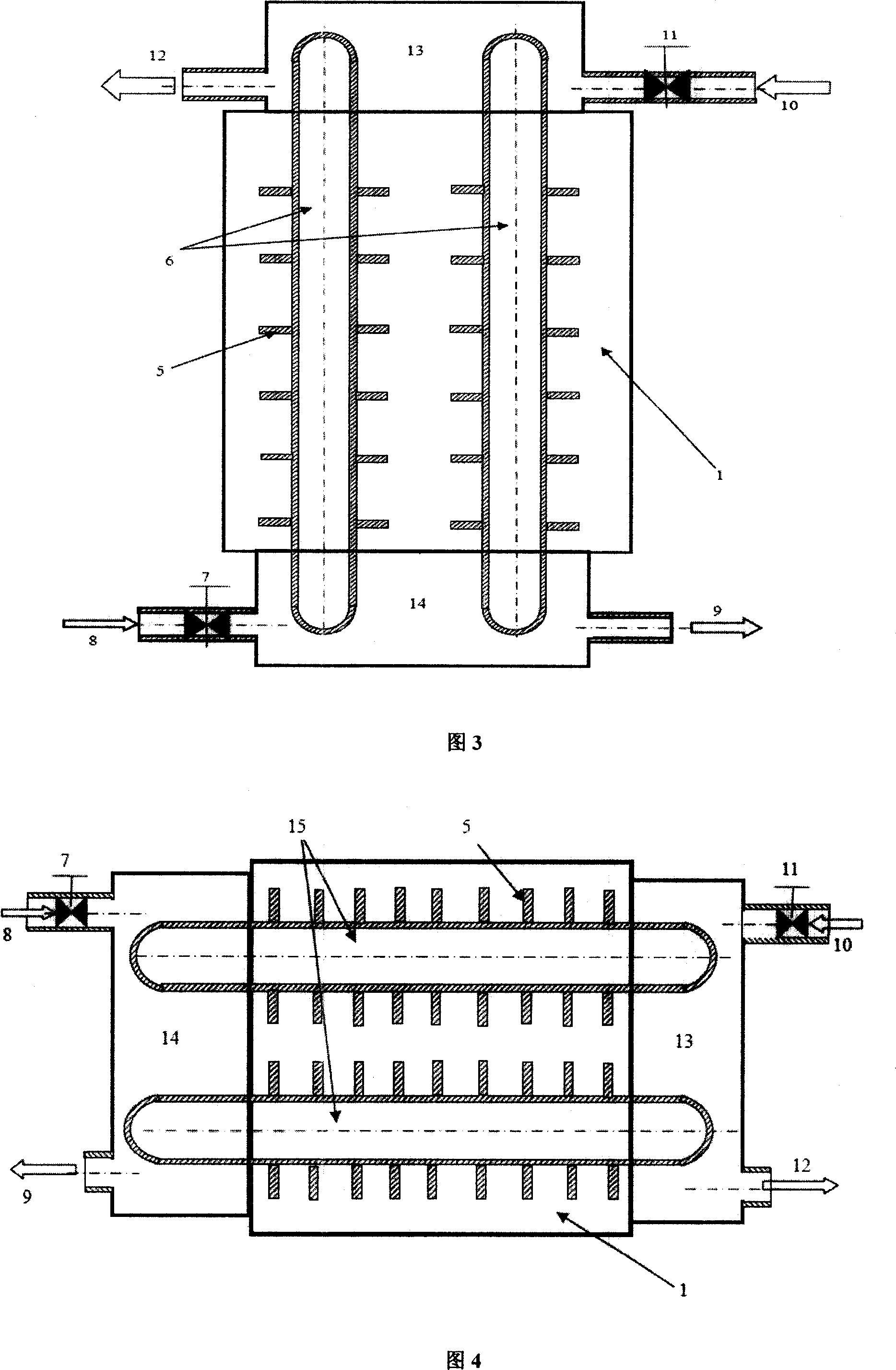

[0017] From Figure 1, the concrete heat storage block (1) is made of concrete with a density of 2.98g / cm 3 , the specific heat at constant pressure is 970J / K / kg, the thermal conductivity is 1.75W / m / K (room temperature 25°C), the refractoriness is 1000°C, the storage temperature is increased from 300°C to 600°C, and the size of the concrete heat storage block is 1m×1m×1.5m, the stored heat energy is 361.325kWh, and the total stored heat per unit volume can reach 240.8kWh / m 3 . The heat exchanger pipe (2) adopts a metal pipe or a non-metal pipe, the inner and outer walls of the pipe are kept smooth, the pipe (2) is buried in the concrete heat storage block (1), and maintains a suitable distance, and one end of the pipe (2) is a fluid The inlet (3), and the other end is the fluid outlet (4). When the concrete heat storage block (1) is heated, the high-temperature fluid flows in from the inlet (3) and flows out from the fluid outlet (4) at the other end, completing the heat stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com