Emulation test-bed of vehicle electric power-assisted steering device

An electric power steering and test bench technology is applied in the field of simulation test benches to achieve the effect of saving test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Further illustrate the present invention below in conjunction with accompanying drawing.

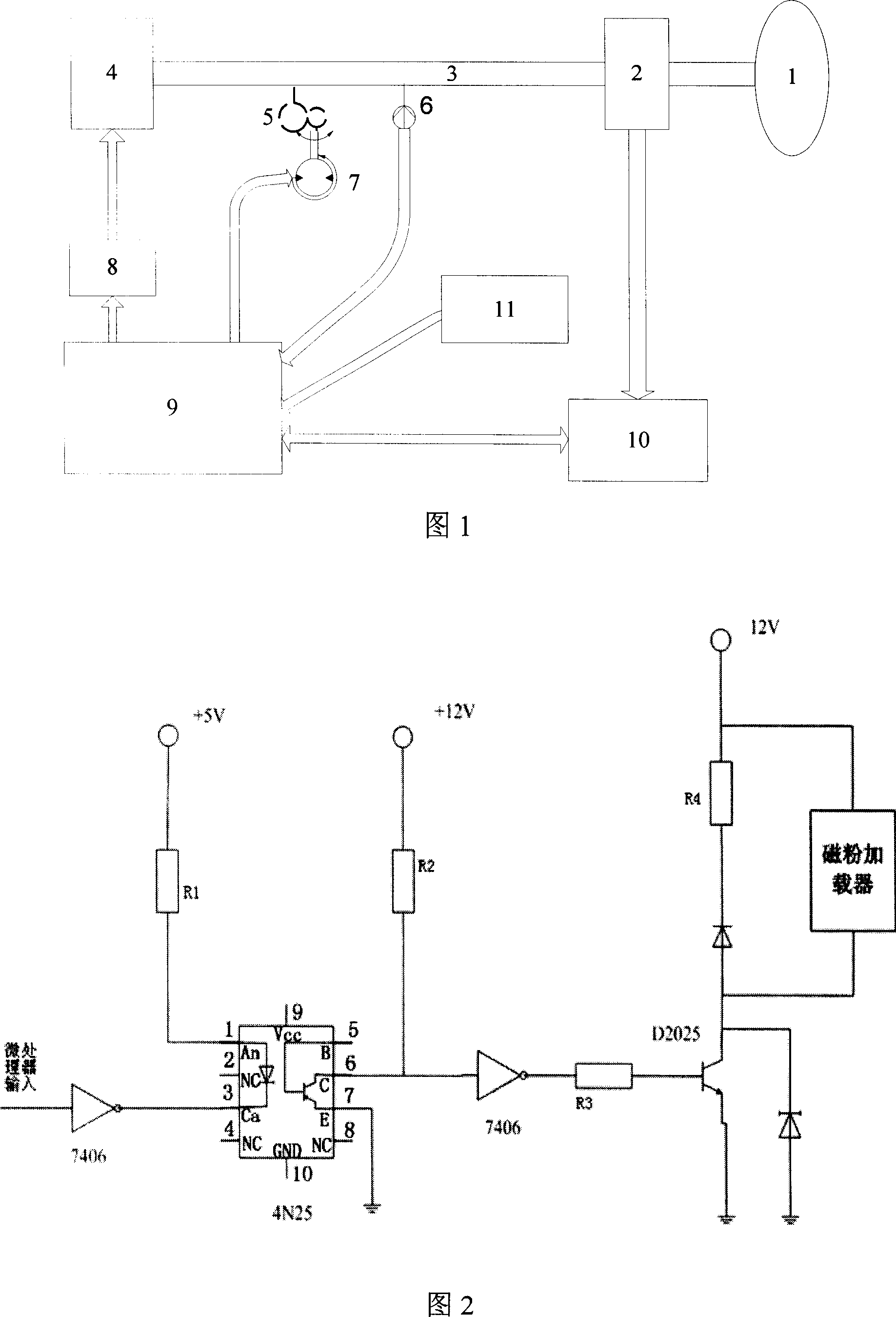

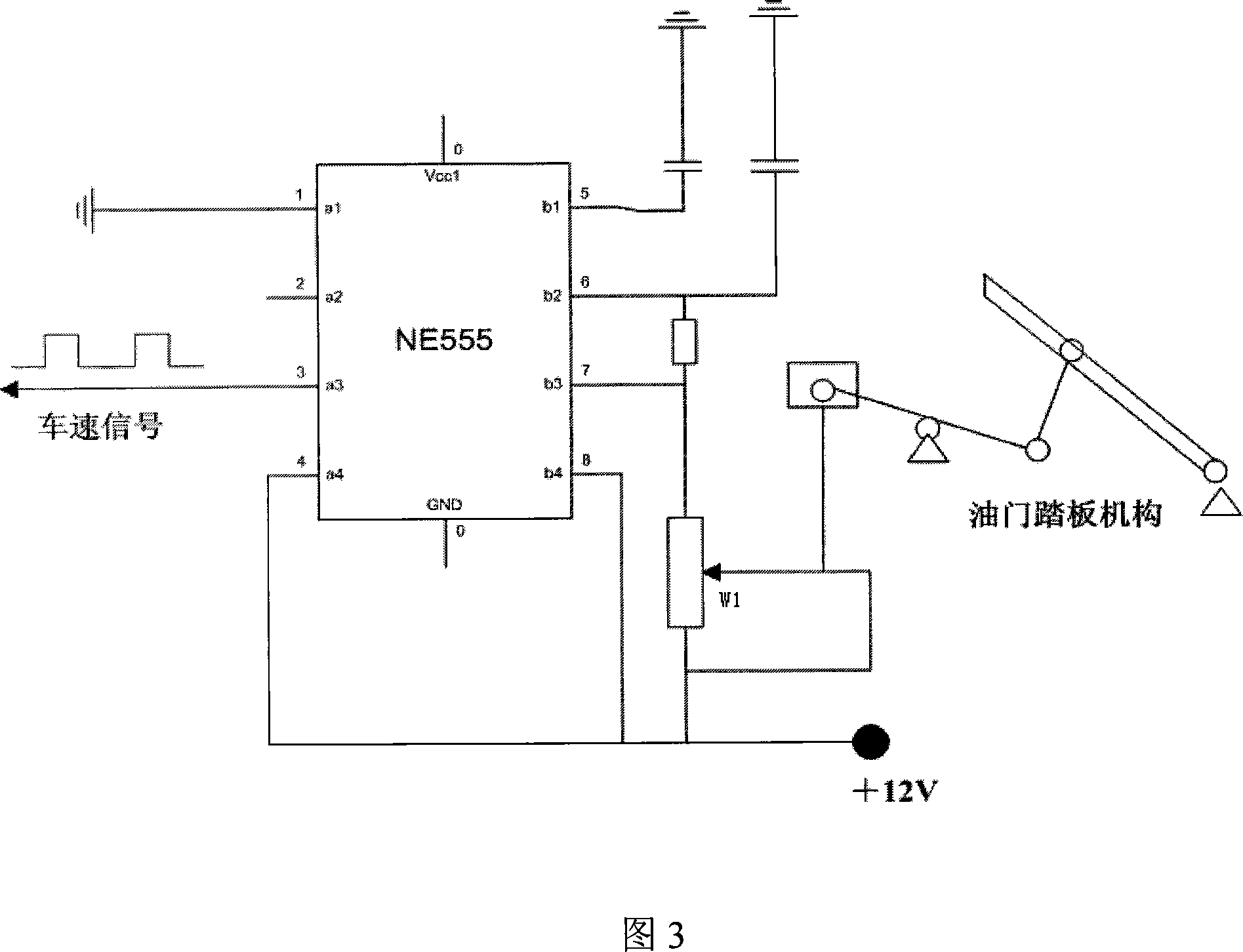

[0023] With reference to Fig. 1, the simulation test bench of automobile electric power steering of the present invention comprises automobile steering wheel 1, electric power steering device 2, automobile steering column 3, magnetic powder loader 4, angle sensor 6, servomotor 7, magnetic powder loader drive Circuit 8, microprocessor 9, computer 10 and vehicle speed signal generator 11 controlled by the pedal. Wherein the automobile steering wheel 1 is fixedly connected with the automobile steering column 3, the electric power steering device 2, the angle sensor 6 and the magnetic powder loader 4 are installed on the automobile steering column 3, and the rotating shaft of the servo motor 7 passes through the gear meshing mechanism 5 It is connected with the steering column 3 of the automobile, the output end of the rotation angle sensor 6 and the output end of the vehicle speed si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com