Chip welding spot on-line detecting, defect identification device and chip packaging device

A chip and defect technology, applied in the field of chip solder joint inspection, can solve problems such as unfavorable chip real-time inspection and system integration, and achieve the effect of low price and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

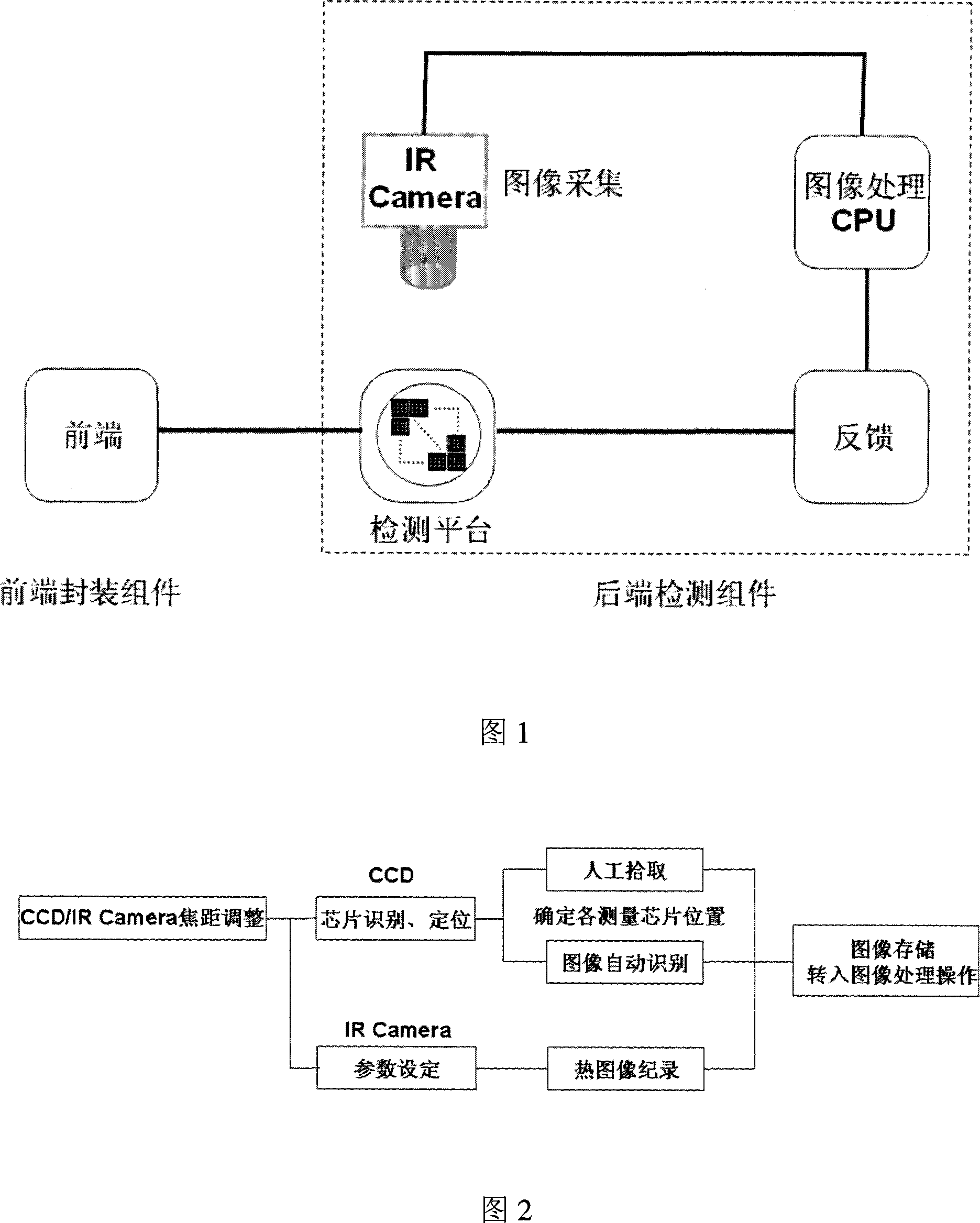

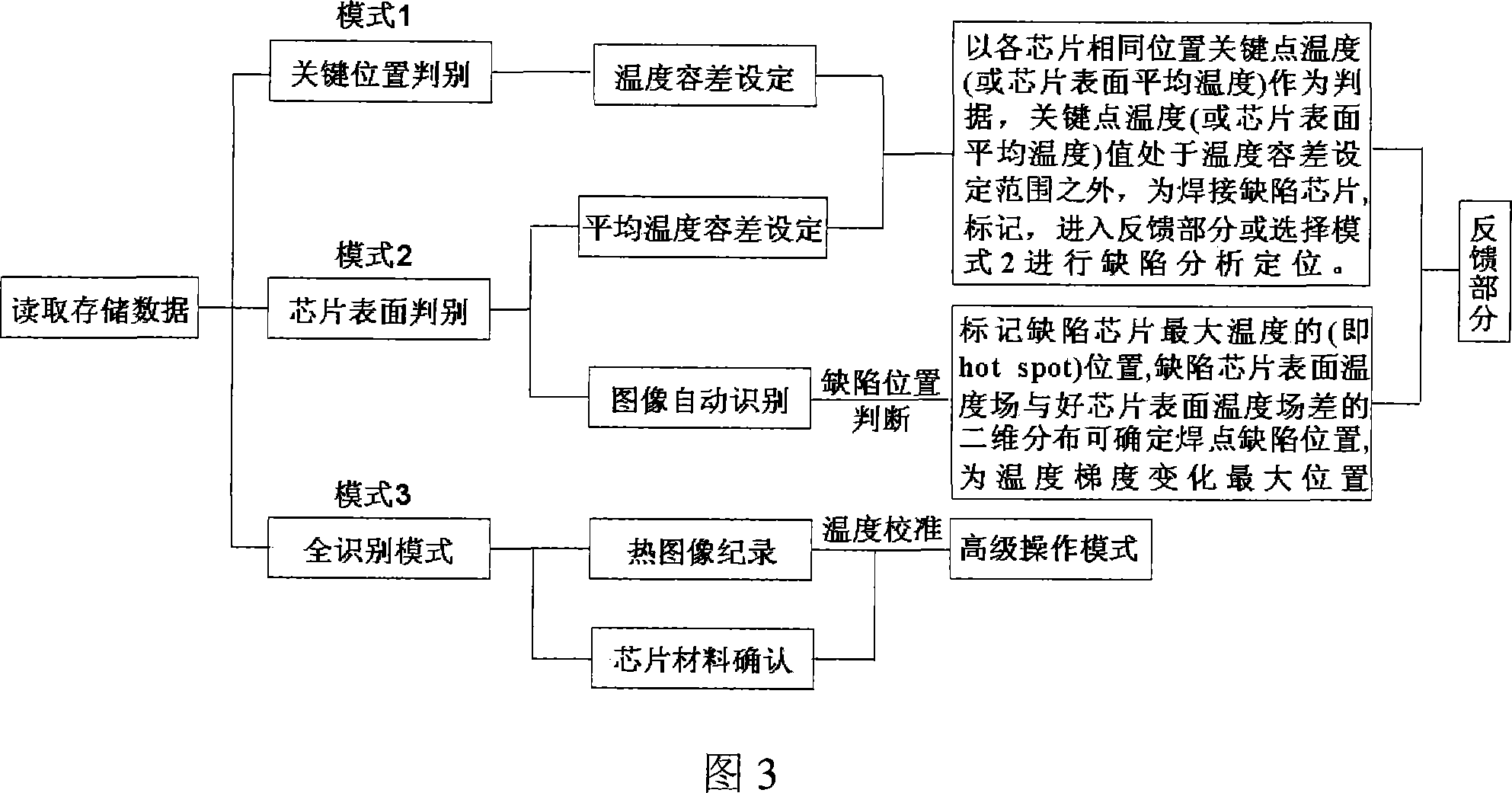

[0029] The structure diagram of the online detection and defect identification equipment of the present invention is shown in Figure 1. It is composed of a front-end interface, a detection platform, an image acquisition device, an image processing system and a feedback device; the front-end interface serves as a connection bridge with the front-end packaging components , The solder joint inspection platform components are integrated with the front-end packaging components through the front-end interface; the inspection platform is responsible for processing the chip samples transmitted from the front-end; the image acquisition device includes CCD image acquisition and IR Camera infrared thermal imaging system, CCD image acquisition system for chip For positioning and automatic measurement, the IR Camera infrared thermal imager collects the surface temperature of the chip s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com