Buried arc stud welding machine and operation method thereof

A technology of a stud welding machine and an operating method, applied in arc welding equipment, welding equipment, welding equipment and other directions, can solve problems such as difficulty in clamping and lifting steel bars, and achieve significant economic and social benefits, less heat loss, The effect of short welding times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

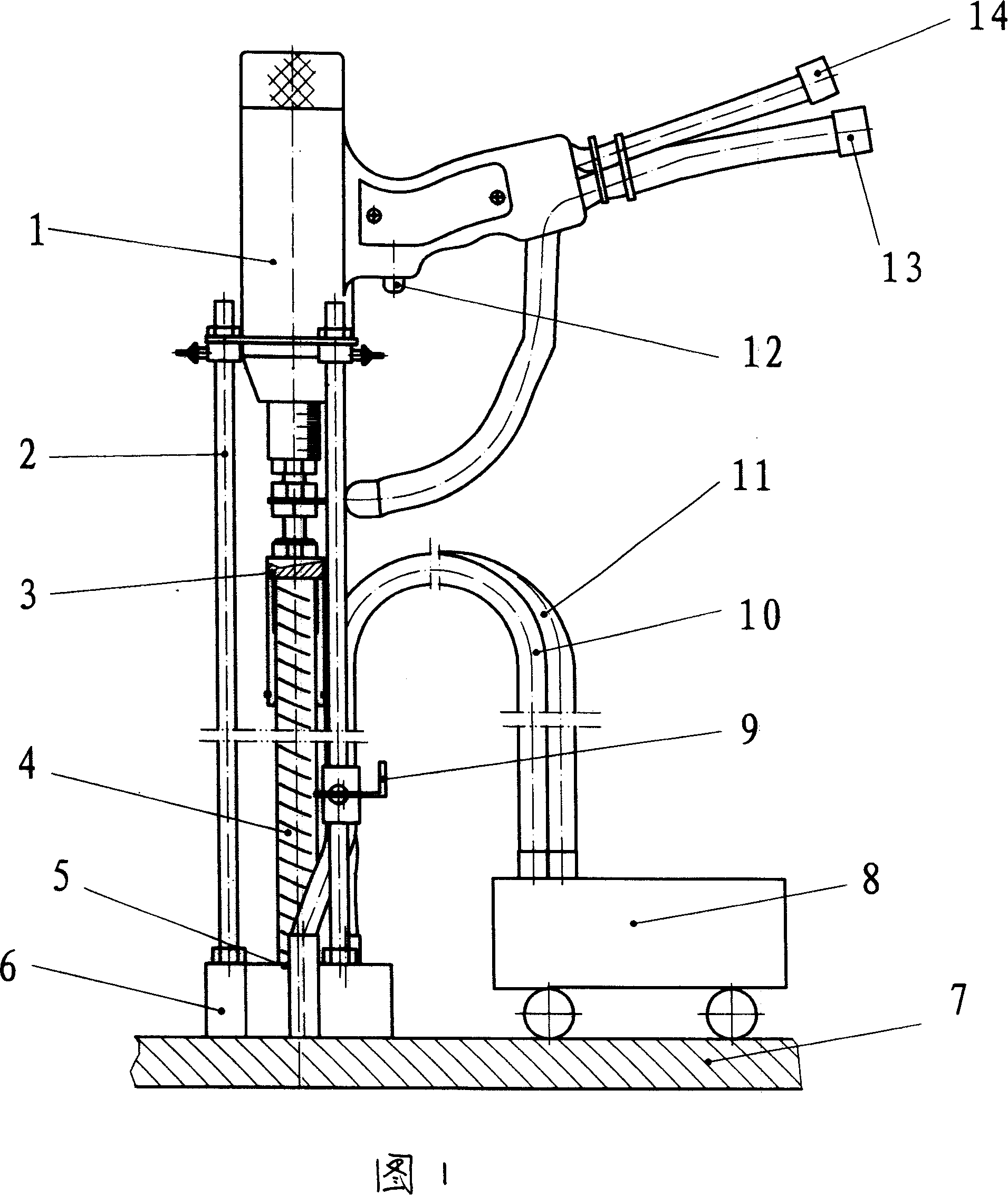

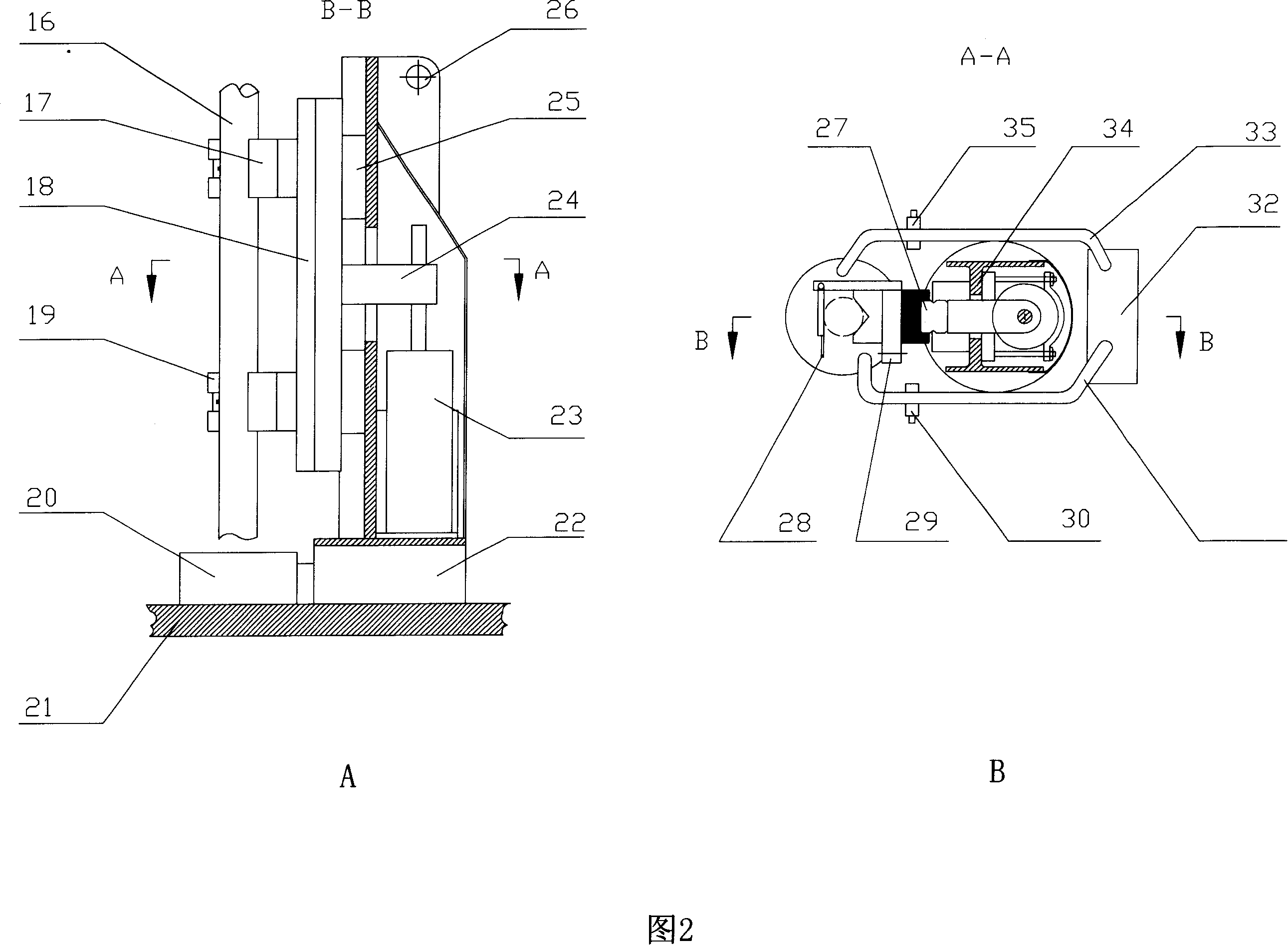

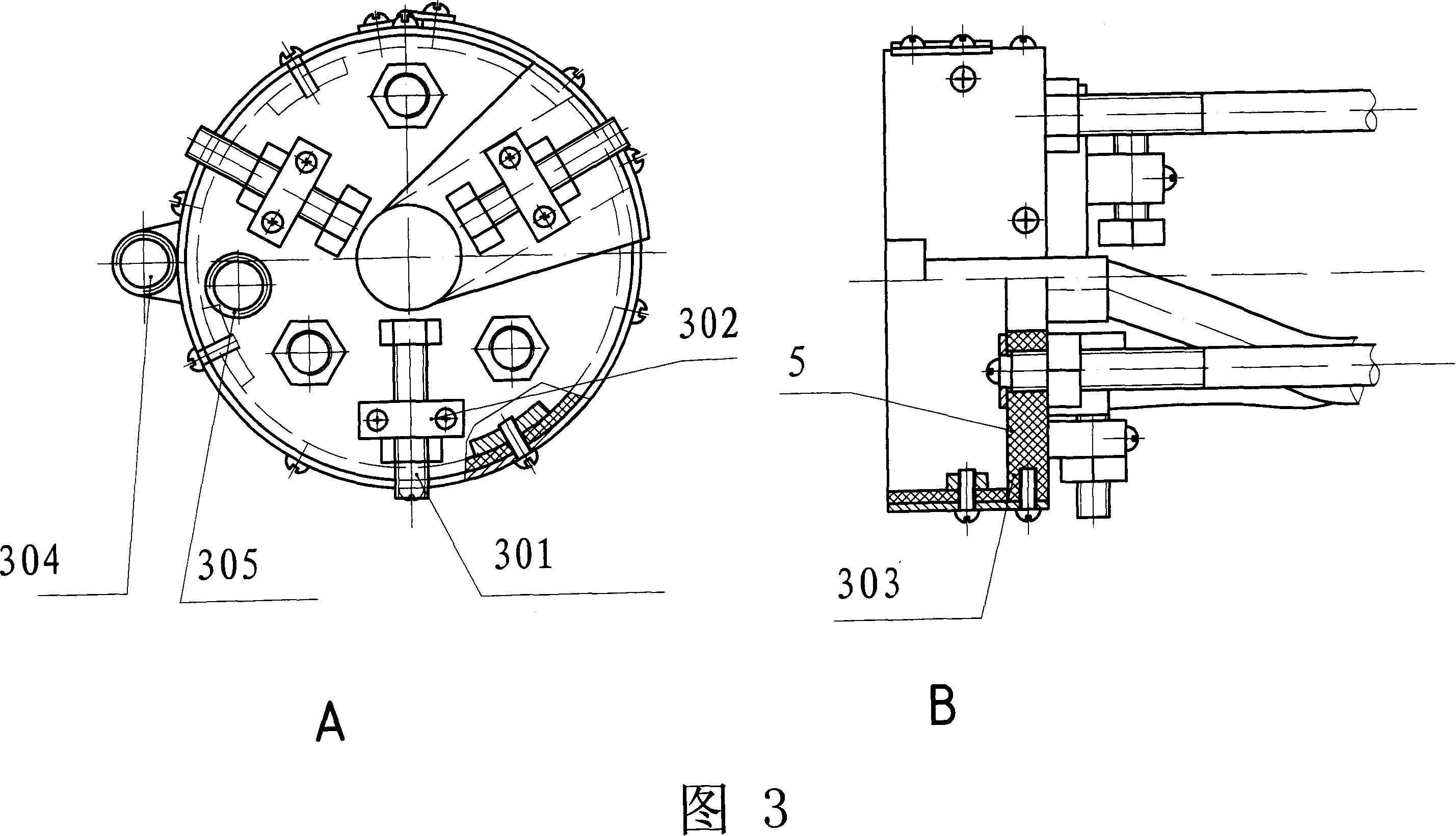

[0033] The submerged arc stud welding machine provided by the present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] Fig. 1 is the structural representation of the hand-held welding device provided by the present invention, wherein, 1, welding torch, 2, support bar, 3, weldment chuck, 4, steel bar (weldment), 5, flux box, 6, Box door, 7. Work piece to be welded, 8. Flux cartridge, 9. Control valve (including delivery valve and recovery valve), 10. Recovery pipe, 11. Delivery pipe, 12. Welding button, 13. Main cable and its plug, 14. Control cables and their plugs. Submerged arc stud welding machine equipped with hand-held welding device, including welding device, welding power supply, controller, ground wire clamp connected to the workpiece to be welded, welding cables and other components. The welding power supply is a DC power supply that outputs a large current instantaneously, and has a reduced static external character...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com