Sandwich panel including honeycomb structure body and method of producing the sandwich panel

A technology of honeycomb structure and sandwich panel, which is applied in the direction of building structure, chemical instruments and methods, building components, etc. It can solve the problems of no air permeability of the undisclosed outer covering plate, and achieve good appearance, simple processing, and easy tidy end faces Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

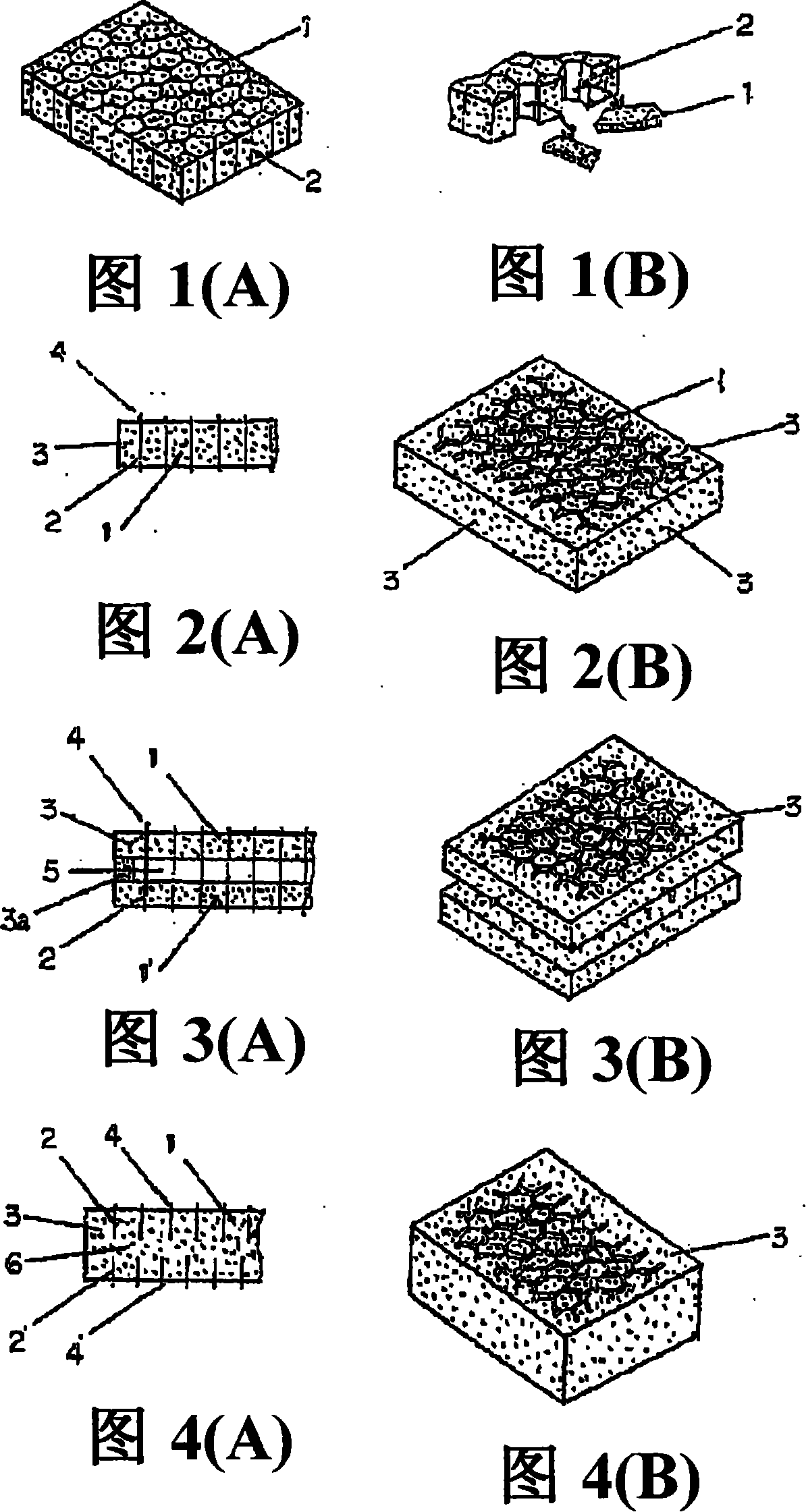

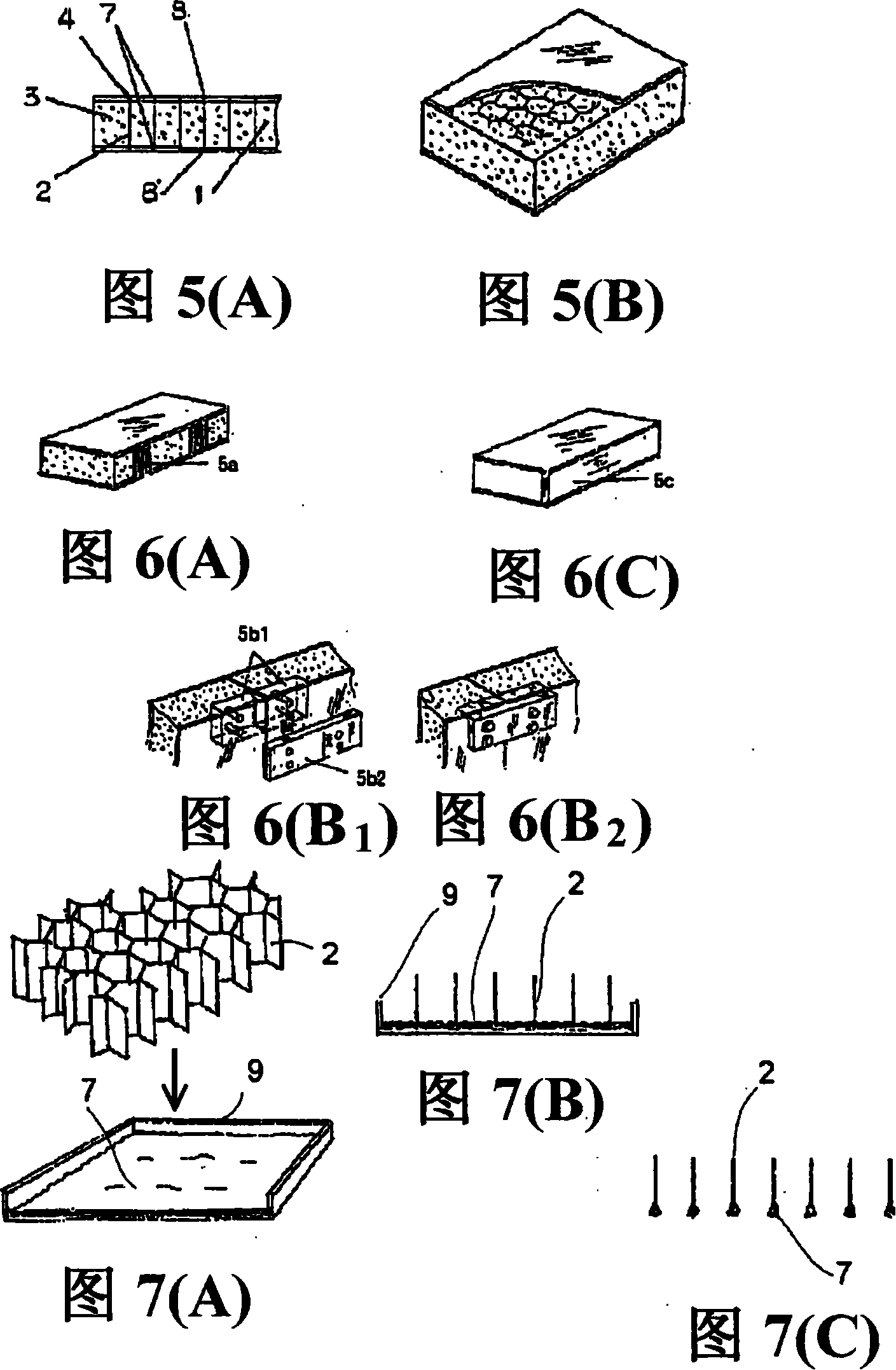

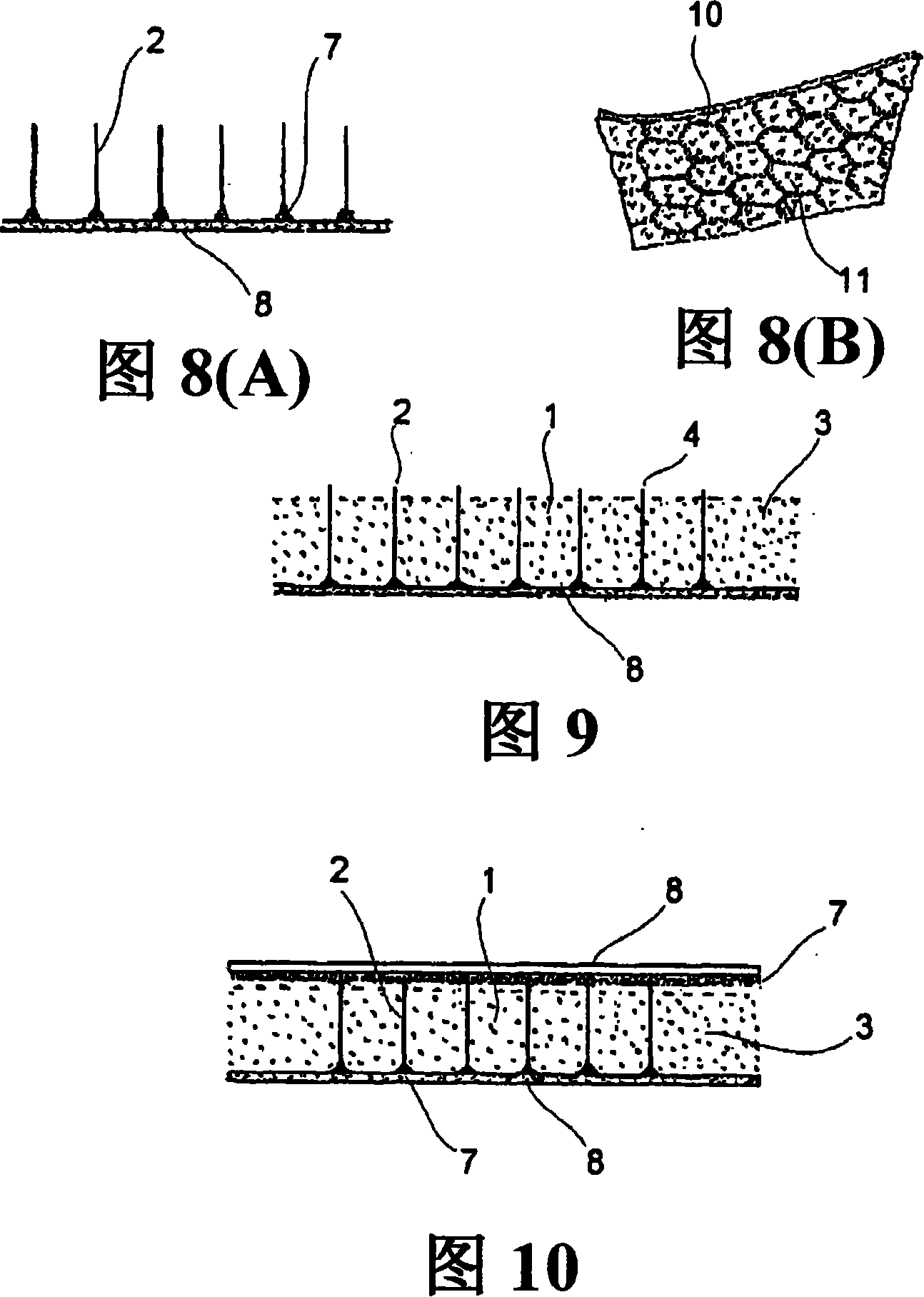

[0055] According to the first embodiment of the present invention, in the honeycomb structure, one or both ends of the honeycomb material in the vertical direction are provided with protruding portions protruding from the surface of the filling material by a predetermined length.

[0056] When using the honeycomb structure with the above-mentioned protruding part as the core material and bonding the surface material on it to manufacture a sandwich panel, the adhesive is only applied to the front end of the protruding part, and the adhesive is not applied to the surface of the filling material. Sandwich panel manufacturing methods are available.

no. 2 example

[0058] In the second embodiment of the present invention, in the above-mentioned honeycomb structure, two filling sheets are filled in the longitudinal direction of the honeycomb material honeycomb, and between the two layers of filling material layers inside the honeycomb material, there is no filling material. air layer.

[0059] Since the air layer of this embodiment is provided in the honeycomb structure, the sound-absorbing performance from low frequency to high frequency is improved, so that a sound-absorbing material corresponding to full audio frequency can be obtained.

no. 3 example

[0061] In the third embodiment of the present invention, in the above-mentioned honeycomb structure, the two honeycomb materials are pressed into the two honeycomb materials from the upper and lower sides of the sheet-like phenolic foam material whose thickness exceeds the total height of the two honeycomb materials. There is no honeycomb material in the middle part, and a layer consisting of filling material only is provided.

[0062] By providing an intermediate layer (there is no layer of honeycomb material) consisting only of the filling material of this embodiment in the honeycomb structure, the heat conducted to the wall of the honeycomb material is blocked by the intermediate layer, and the foam material constituting the intermediate layer becomes an insulating material. thermal layer. If the middle layer is thickened, the thermal insulation performance is improved, and the honeycomb material layer on both sides becomes the protective layer of the foam material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com