Powder granule circulation whirlwind multi-level grading device

A particle classification and classification device technology, which is applied in the swirl device, the device whose axial direction of the swirl can be reversed, organic chemistry, etc., can solve the problem of inability to recover large catalyst particles, decrease the activity of the catalyst bed, and improve the production of acrylonitrile Cost and other issues, to achieve the effect of preventing short circuit and hoisting of particles in the cone, high operating flexibility, and improved separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

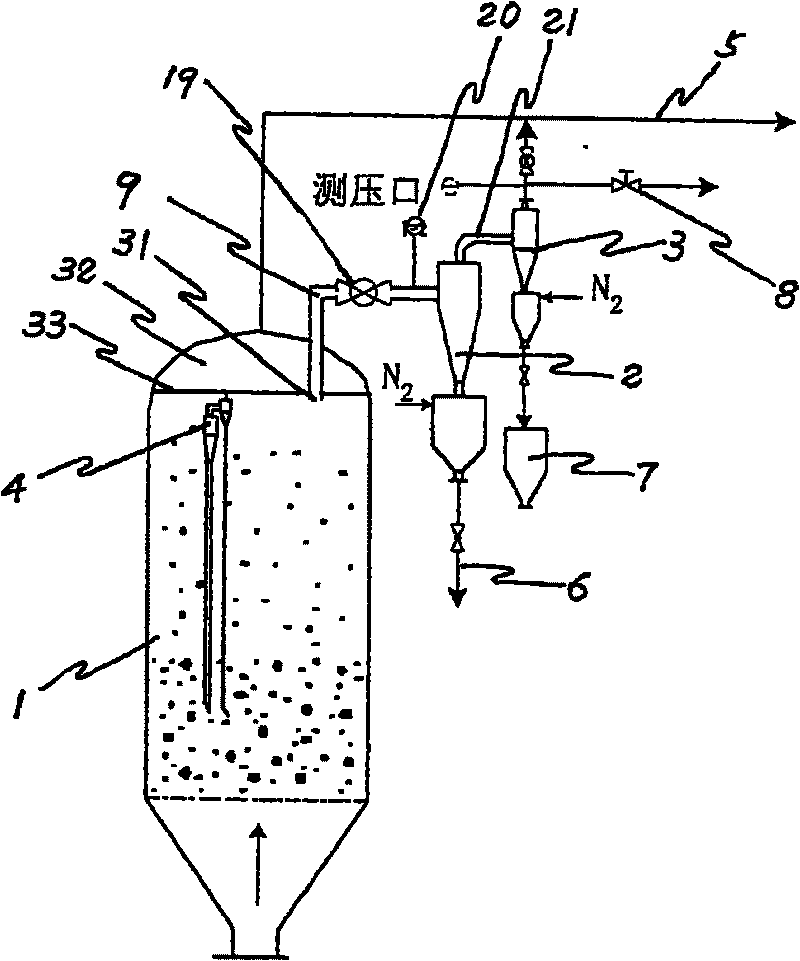

[0042] Example 1. A circular cyclone multistage classification device for powder particles, which is also used for the classification of catalyst particles in acrylonitrile fluidized bed reactors, such as figure 1 , figure 2 and Figure 5 shown. It includes a particle classifier 2 and a circulating cyclone dust collector 3 connected to the top of the acrylonitrile reactor 1 through a suction pipe. Reactor 1 is equipped with an internal cyclone dust collector 4. 5 is the follow-up gas system of reactor 1, 6 is the catalyst replenishment system, 7 is the fine catalyst storage tank, 8 is the gas release valve, and 9 is the exhaust pipe. Have valve 19 and air pump 20 on the suction pipe 9.

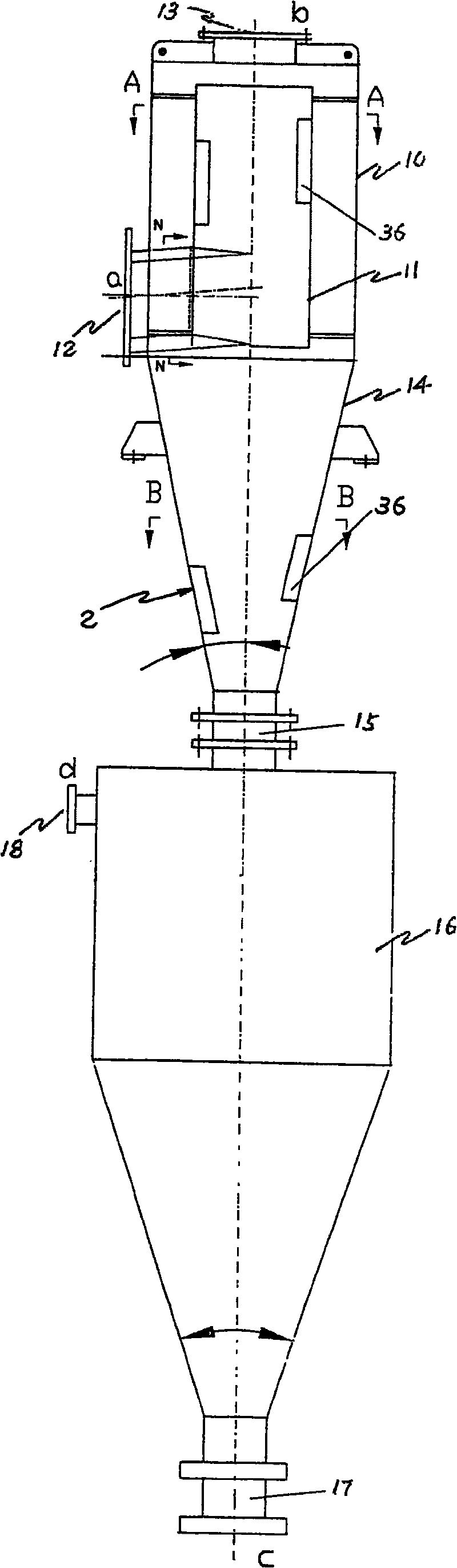

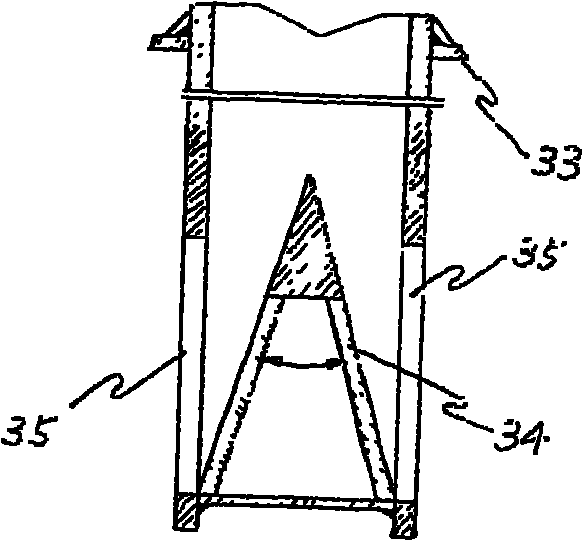

[0043] The particle classifier 2 consists of a straight cylindrical body 10 with a top overflow port 13, a straight cylindrical inner part 11 symmetrically fixed in the straight cylindrical body 10, and a gas inlet tangentially entering the inner part 11 from the lower part of the straigh...

Embodiment 2

[0047] Example 2. A method for classifying powder particles according to claim 1 using a circulating cyclone multi-stage classifying device and used for classifying catalyst particles in an acrylonitrile fluidized bed reactor. It includes the following steps:

[0048] (1) extract the dusty gas from the top of the acrylonitrile fluidized bed reactor with a pipeline and introduce it into the particle classifier;

[0049] (2) Use a particle classifier to separate the catalyst particles above 15-20 μm, and send them back to the reactor by the catalyst replenishment system;

[0050] (3) The gas discharged from the particle classifier is introduced into the circulating cyclone dust collector;

[0051] (4) The catalyst fine particles below 15 μm are removed by a circulating cyclone dust collector and discharged into the fine catalyst storage tank, and the gas after removing the catalyst fine particles is returned to the gas system of the acrylonitrile reactor.

[0052] Wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com