Steel grid plate composite blade shearing machine

A steel grating and blade technology, which is applied in the direction of shearing machine equipment, shearing machine accessories, shearing devices, etc., can solve the problems of large noise and pollution, material loss, and slow speed, and achieve fast cutting and cutting , Create an effect that is easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

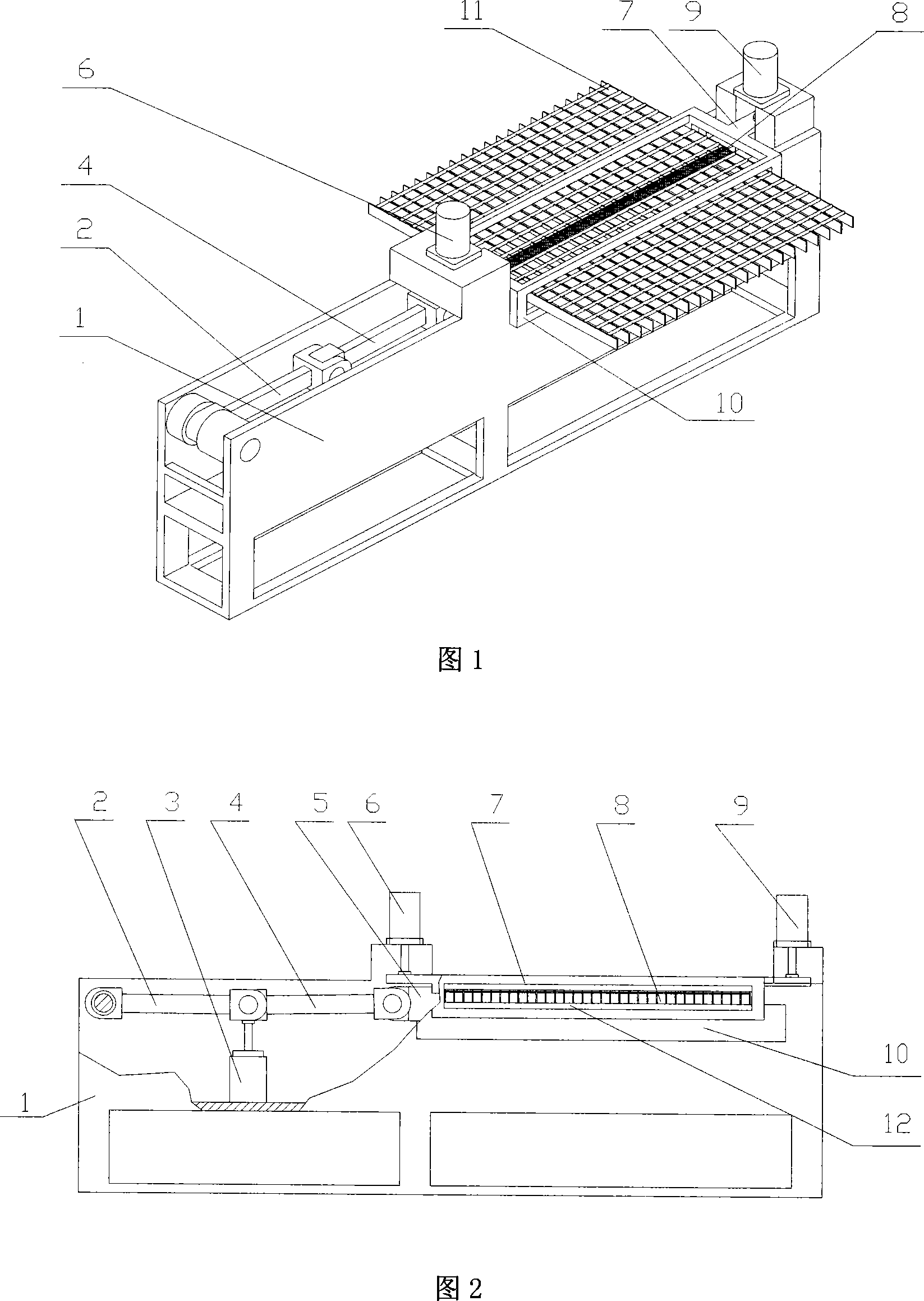

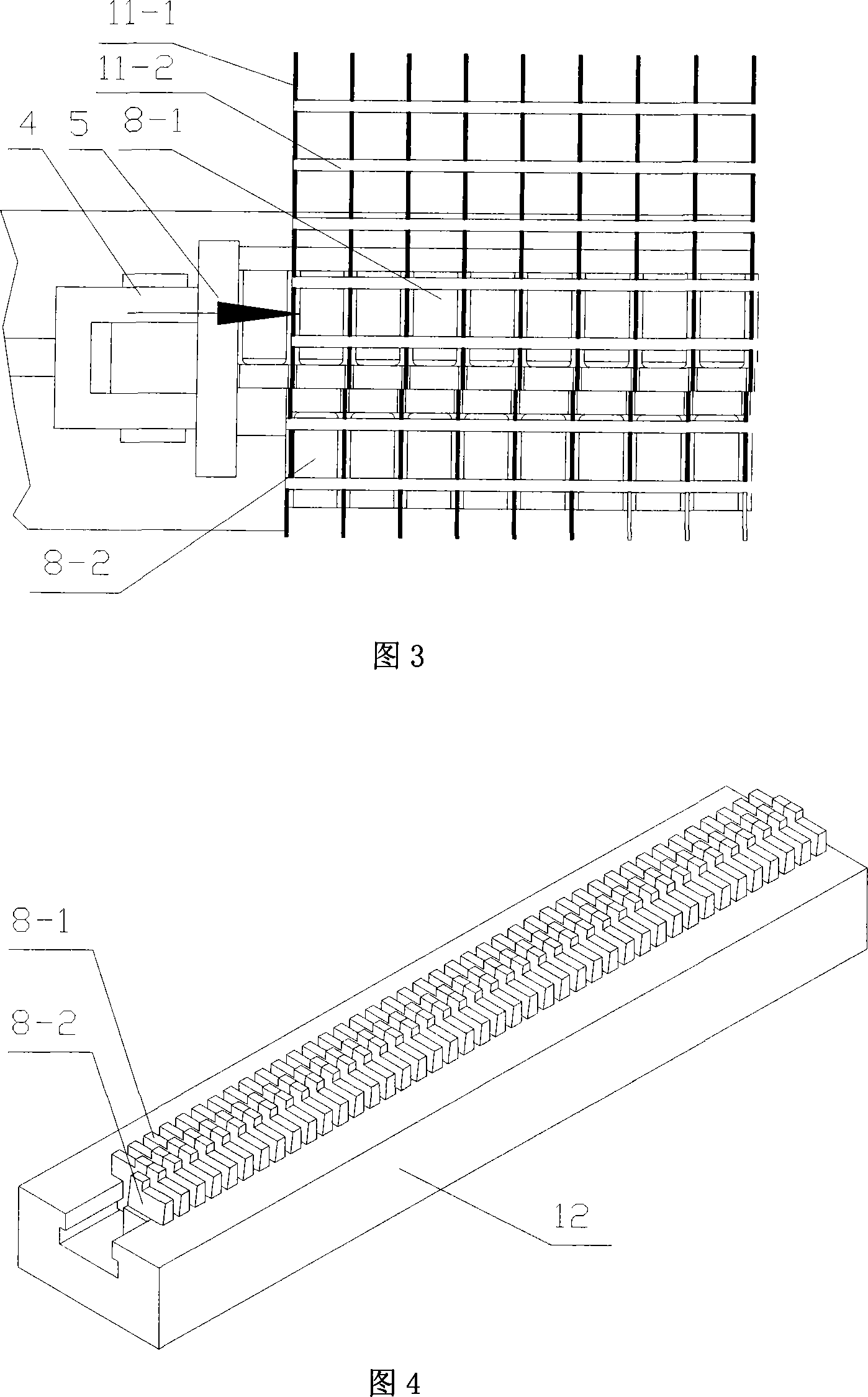

[0012] As shown in Fig. 1, Fig. 2 and Fig. 4, a bed table 12 is arranged inside the machine body 1 of the shearing machine. The bed table 12 is fixed on the bed base 10. The bed table 12 is in the shape of a horizontal platform with a wide opening. Upper narrow trapezoidal groove. An oil cylinder 3 is provided in the inner cavity on the left side of the fuselage 1, and the movable push rod of the upper end of the oil cylinder 3 can move up and down. At the upper end of the movable push rod, the left end of the connecting rod 2 is fixed at the upper left of the fuselage 1, and the connecting rod 2 The right end and the left end of the connecting rod 4 are connected to form a common end, and the common end is connected to the movable push rod of the oil cylinder 3. A guide block 5 is arranged in the middle of the fuselage 1, and its left side is in tight contact with the right end of the connecting rod 4.

[0013] Two rows of combined blades 8 are arranged in the bed 12, which are m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com