System and method for augmenting turbine power output

A power output, gas turbine technology, applied in the direction of turbine/propellant fuel delivery system, cleaning method using liquid, chemical instrument and method, etc., can solve the problems of expensive, power increase, complicated use, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Gas turbines have a wide variety of applications such as power generation, gas compression, and many other mechanical transmission applications. The various aspects presented herein can be used with any type of gas turbine; however, for convenience, the description will be made here in terms of a gas turbine used in a power plant. Those of ordinary skill in the art will readily understand the adjustments required for other types of appropriate turbines.

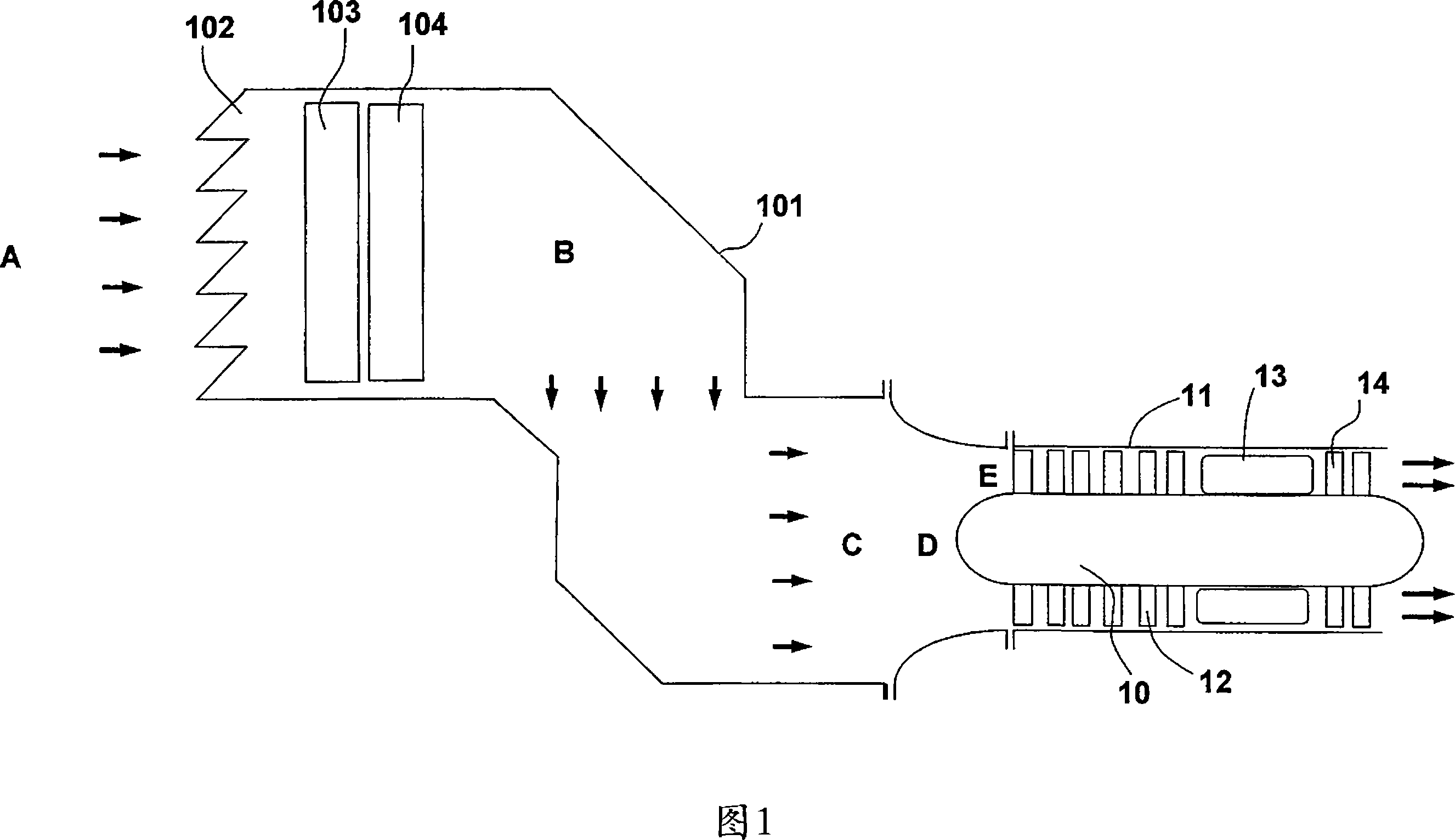

[0031] Figure 1 shows a representative configuration of a gas turbine intake section. Arrows show the direction of airflow. Ambient air enters duct 101 through weather louver 102 , screen 103 and air filter 104 to the inlet of gas turbine 10 . Gas turbine 10 includes a rotor with blades and a casing 11 . At the front end of the shaft, compressor blades 12 compress the air to a high pressure, eg typically 10 to 30 times the normal air pressure. The compressed air is delivered to the combustion chamber 13 . Fuel (no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com