Metal powder laser forming process temperature field detection method and its systematic device

A technology of laser forming and metal powder, which is applied in measuring devices, radiation pyrometry, thermometers, etc., can solve problems such as high cost, harsh processing environment conditions, and processing environment interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

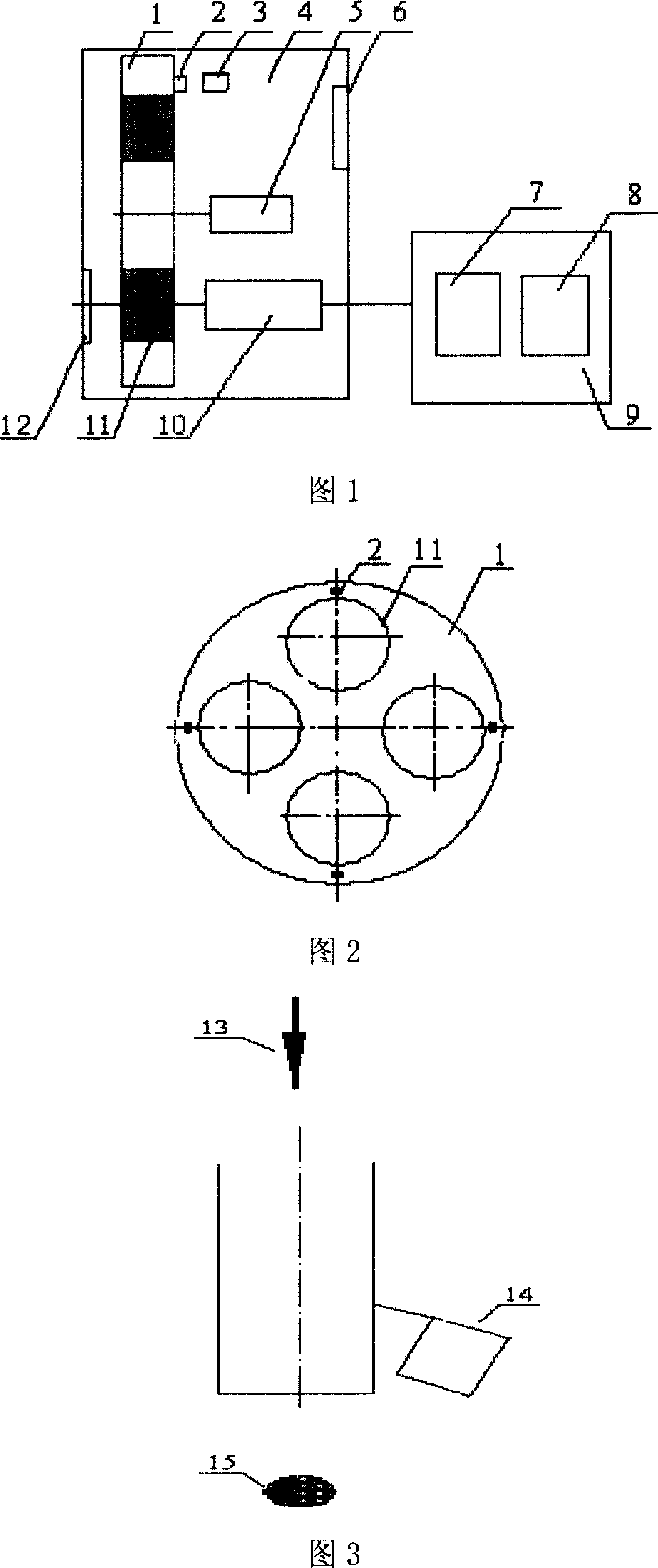

[0043] The present invention will be further described below in conjunction with the accompanying drawings.

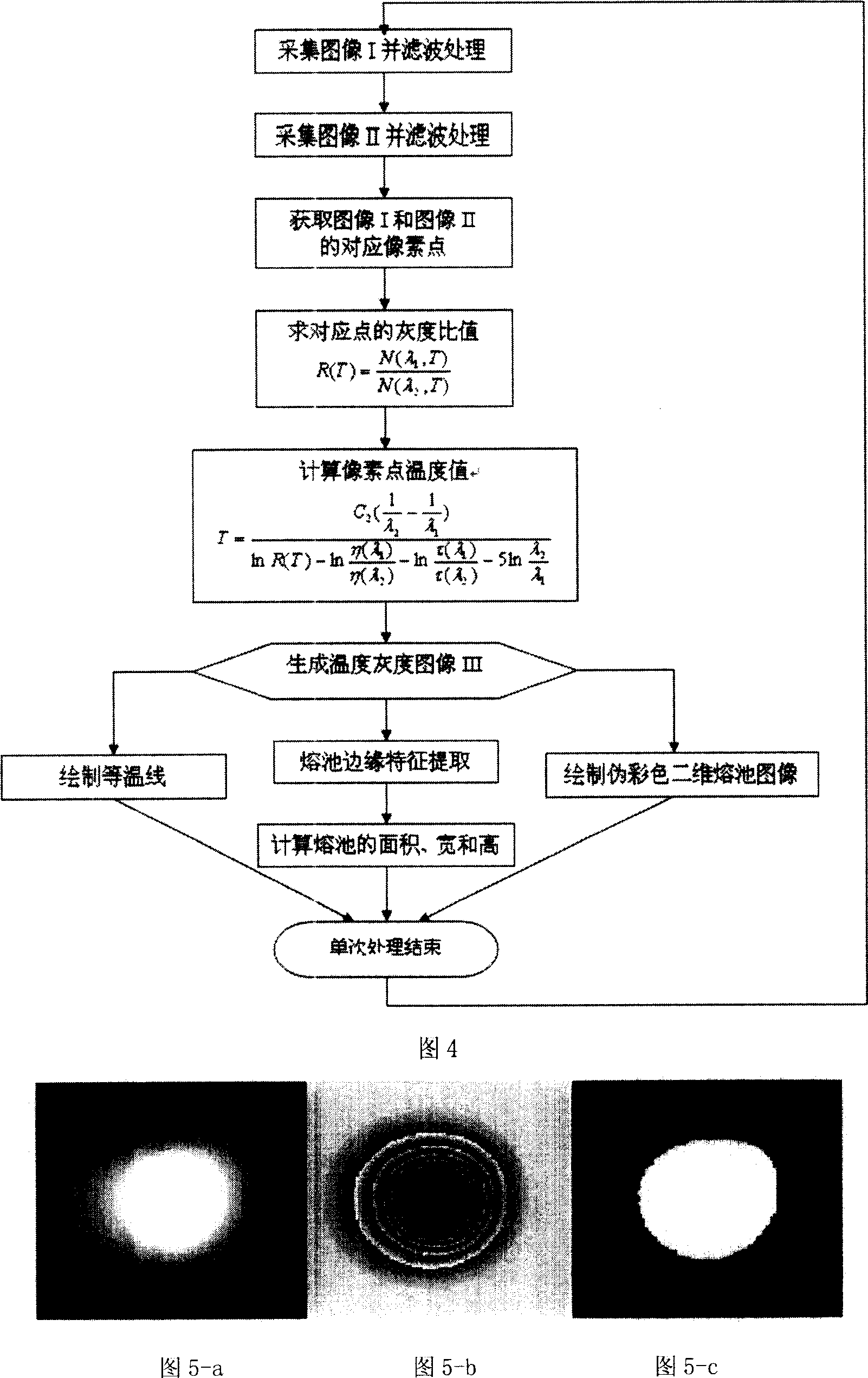

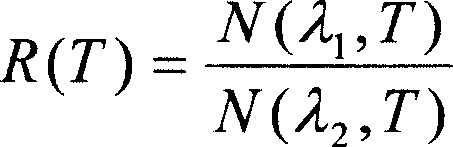

[0044]The temperature field detection method in the metal powder laser forming process of the present invention: adopts the dual-wavelength infrared image colorimetric temperature measurement method, and alternately places the filters of the two wavelengths in the collection optical path in time-sharing, and the step-by-step continuous collection comes from two For the image of the melting pool at different wavelengths, the image grayscale colorimetric calculation is performed based on two infrared images from different wavelengths, and the temperature value of each point on the image is obtained according to the relationship between the ratio and temperature, and the grayscale value is used to represent the temperature value. Furthermore, the grayscale image is processed, and then the generated grayscale image is image-processed to obtain its shape and temperature chan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com